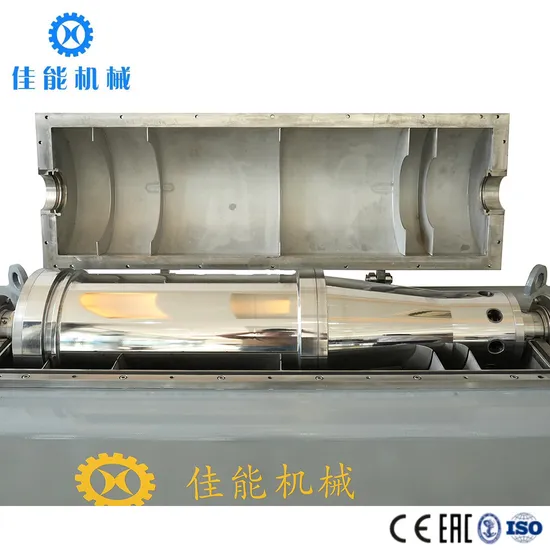

Oat Juice Horizontal Spiral Centrifuge for Efficient Separation

| US$15,000.00-90,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LW Series

Application

Oat Juice

Certification

CE, MET

Power Source

Electric

Automatic Grade

Automatic

Operating Type

Continuous Decanter Centrifuge

Installation

Horizontal

Centrifuge Type

Horizontal Spiral Centrifuge

Feature

High Efficiency

Separation

3 Phase Separation

Discharge Type

Self-Cleaning

Separation Method

Sedimentation Type

Material

SS304 or SS316 L or Ti

Control

PLC Control

Electronic Component

ABB or Siemens

Condition

New

Transport Package

Wood Case

Trademark

JIANENG

Origin

China

Production Capacity

500/Year

Packaging & Delivery

Package Size

600.00cm * 150.00cm * 180.00cm

Package Gross Weight

9500.000kg

Product Description

Company Profile Jiangsu Jianeng Machinery Manufacturing Co., Ltd. is an esteemed and forward-thinking high-tech enterprise, fully owned by Nanjing Jianeng Machinery Manufacturing Co., LTD. Established in 2001, we have continually distinguished ourselves through research, design, manufacturing, and outstanding service quality. Originally founded in the dynamic Nanjing Yuhuatai District, our cutting-edge new facility is strategically located at Jinyuan Road No. 7, Xuyi Economic Development Zone, Huaian City, Jiangsu. This expansive site covers 58,700 square meters, featuring a modern 38,600-square-meter workshop, a sleek 4,000-square-meter office building, and a 2,100-square-meter science and technology building. We are dedicated to producing China's finest disc and decanter centrifuges, achieving a remarkable annual production capacity of 2,000 sets.

Main technical parameters ofdecantercentrifuge | ||||||

Model | LW250 Series | LW350 Series | LW450 Series | LW530 Series | LW580 Series | LW650 Series |

| U. mm Drumdiameter | 250 | 350 | 450 | 530 | 580 | 650 |

| m³/h Water lux | 3 | 10 | 20 | 30 | 40 | 50 |

U. w Main motor power+ Auxiliary motor power | 15+4 | 22+7.5 | 30+11 | 45+15 | 55+15 | 75+22 |

| U. kg Weight | 1100 | 2300 | 4500 | 5500 | 6500 | 9500 |

| U. m Overall dimension | 2.7X0.7X0.85 | 3.54x0.92x1.05 | 4.35x1.12x1.35 | 4.6x1.25x1.52 | 5.12x1.3x1.48 | 5.58x1.35x1.65 |

Procedure Control

At Jiangsu Jianeng Machinery, our esteemed reputation is anchored by a state-of-the-art quality inspection and test center. Outfitted with advanced tools like chemical analyzers, product test benches, high-precision dynamic balances, coordinate measurement machines, Vickers hardness testers, imagers, flaw detectors, profilers, and coding machines, we guarantee exceptional product quality and excellence that stands unrivaled. Our exhaustive and meticulous testing protocols, combined with cutting-edge equipment, ensure outstanding quality and dependability throughout every phase of the manufacturing process.

Product Equipment

Jiangsu Jianeng Machinery prides itself on possessing a full spectrum of advanced production capabilities, spanning machining, surface treatment, cold welding, testing, test stands, installation, and commissioning. Our state-of-the-art facility houses over 300 pieces of leading-edge equipment, including CNC boring and milling centers, CNC turning centers, gantry machining centers, sophisticated testing tools, parts painting production lines, shot peening production lines, welding equipment, surface treatment machines, and high-precision dynamic balancing equipment. This comprehensive array of machinery enables us to maintain complete process independence and assure unmatched product quality. With superior processing and testing equipment, highly skilled technical personnel, scientific manufacturing methodologies, and strict compliance with national military standards and quality management systems, we unwaveringly adhere to our core principles of 'management, quality, and efficiency' across all business ventures.

One-stop Services

We offer an all-encompassing suite of one-stop services, including a plentiful supply of spare parts, expert commissioning, repair, maintenance, and adept technical consultations, all designed to support our valued customers with excellence. Sufficient Spare Parts and Standby Machines

Our robust, self-reliant production capabilities across the entire process empower us to consistently deliver products of exceptional quality, exceeding industry standards with each creation.

>> MAICTOP car accessories car hood engine grille for tundra chromed trim 2018-2021

>> Body Kit for Hyundai Tiburon 2003-2006

>> Fashion Cheap Colored Jacquard Socks Sport Athletic MID Calf Ribbed Crew Dress Sock

>> All-Steel Ceramic Tile Height Adjuster Foot Lifter Lifting Positioning Pad High Bricklayer Paving Wall Tile Hardware Tools

>> Kdcl-15h High Precision CNC Lathe Machine with CE

>> Fish Net Rope Fabric with Heavy Duty Polyester Tire Cord Reinforcement Material

>> Digital Electroencephalogram Machine 24 Channel Mapping System Portable Device EEG Medical Equipment

>> Quality Paper Cover Machine, Paper Roll Making Cover Machine, Cover Forming Machine

>> High-Performance Aluminum Anti-Static Raised Flooring for Data Centers & Commercial Spaces Durable Corrosion Resistant Heavy Load Capacity

>> Automatic Multilayer PVC Tile Production Line, Lvt Floor Making Machine

>> 800/900/2100/2300/2600MHz Patch Adhesive LTE Antenna, 3 Meters RG174 Cable Fakra Connector Compatible with 3G 2G 4G Antenna

>> No MOQ Promotion 2D/3D Rubber Soft PVC Items for Gift

>> Eyebrow Pencil Rotating Positioning Laser Marking and Sorting Machine for Any Circular Product

>> Extra Soft and High-Temperature Resistant 200 Degree Single Core 26AWG 24AWG 22AWG 12AWG 10AWG 24AWG Silicone Wire Red/Black Heat-Resistant Wire

>> Violin Salzburg and Mozart Resin Fridge Magnet

>> High Quality Foam Machine Horizontal Styrofoam Cutters Hot Wire Continuous Foam Cutter mattress Cutting Machine

>> 99450797 Camshaft Position Sensor for Trucks

>> Xj250 Xj350 Xj450/Xj550 Xj650 Xj750 Workover Rig Oil Drilling Rig Truck Mounted

>> High Surface Hardness and Wear Resistance PCD Profile Cutters Tools for Click Slotting Machine

>> Ifak Mobile Pouch Emergency Backpack and Safety Individual Medical First Aid Kit Outdoor

>> 350/500ml Double Wall Stainless Steel Vacuum Insulated Tea Bottle with Custom Logo and Painting

>> HC-I037K 93% Purity portable oxygen concentrator oxygen concentrator 10l oxygen concentrator

>> Waste Plastic HDPE PP Container Bottle Barrel Drums Regrind Recycling Washing Machine Plant

>> Strong Resistance Bullet Shape Brass Metal Aglet Tip for Shoelace Cord End

>> 10ci 13ci 22ci 26ci 30ci 48ci Paintball Cylinder

>> Flaxseed Corn Black Seed Screw Automatic Hot Price Peanut Olive Coconut Cold Small Mini Oil Press Machine

>> micro hole expanded metal mesh wholesale

>> Afar Ethiopia Ethiopian Salt Processing Equipment

>> Lightweight Plastic Pallet for Easy Handling and Transportation

>> Steering Wheel Gear Motor 12V 24V 50W Direct Drive Torque Motor Low Speed 80rpm