The Evolution of Paper and Carton Cutting Machine Exploring Technology, Design, and Applications in Industrial Packaging

Basic Info.

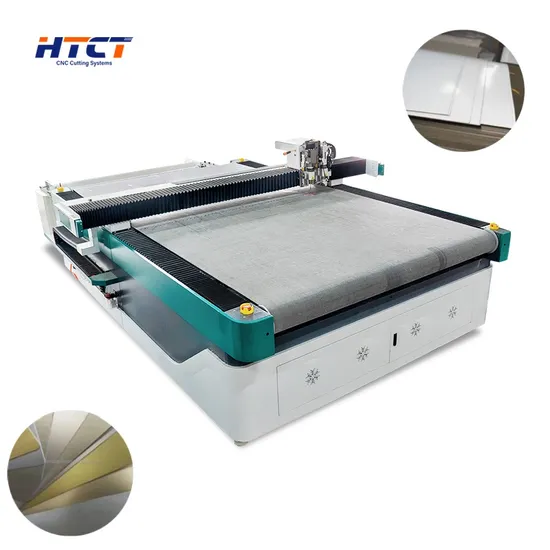

Model NO.

VCM Pro 1625

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Condition

New

Control

Automatic

Application

Paper, Plastic, Leather, Fabric

Power Source

Electric

Layout

Horizontal

Applicable Industries

Advertising Industry

Core Components

PLC, Engine, Bearing, Gearbox, Motor, Pressure Ves

Working Area Size(W*L)

Customized,1.6m*1.2m~2.2m*6m

Cutting Thickness

0.1mm--110mm (After Vauum Adsorption)

Cutting Precision

0.1mm

Maximum Speed

1500 mm/S

Drive Type

Panasonic Servo Motor

Customize

Size, Power Supply, Color, etc.

Control Panel

LCD Touch Screen

Rated Power

11kw

Rated Voltage

220/380V

Transport Package

Wooden Crate Packaging

Specification

W2200mm*L3100mm*H900mm

Trademark

HTCT

Origin

China

HS Code

8451500000

Production Capacity

5000sets/Year

Packaging & Delivery

Package Size

320.00cm * 230.00cm * 160.00cm

Package Gross Weight

1500.000kg

Product Description

Blade Cutter Honeycomb Box Foldable Corrugated Packaging Carton Cardboard Knife Cutting MachineProduct Parameters| Product Series | HT-VCM | |||||

| Model | VCM-1012 | VCM-1625 | VCM-1830 | VCM-2030 | VCM-2230 | Customizable Model |

| Cutting area (W*L) | 1.0m*1.2m | 1.6m*2.5m | 1.8m*3.0m | 2.30m*3.0m | 2.20m*3.0m | Size can be customized |

| Production Capacity | Capable of producing up to 15,000 cut pieces per day | |||||

| Cutting length | No limitation with automatic feeding system | |||||

| Cutting Thickness | 0.1mm--110mm (after vauum adsorption) | |||||

| Spreading length | Maximum 50m with spreading table | |||||

| Cutting precision | ± 0.1mm | |||||

| Maximum Speed | 1.5 m / s |

| Total Power | 11KW |

| Power Supply | 220V/380V , 50/60HZ |

| Cutting style | Straight Knife Continous Up-down Cutting |

| Adsorption method | Frequency conversion vacuum constant pressure control mode |

| Compressed air | 550KPa , 160L/min |

| Operating panel | Touch control panel |

| Operating System | Windows OS |

| System Features | Supports the overall rotation of the nesting chart, knife-edge conversion, single-piece recutting, one-key deletion of overlapping areas (supports removal of repeated lines) |

| File Format | cut , dxf , plt , iso ,pdf , ggt , gbr,hpgl |

| Applied Materials | Corrugated paper,Cardboard,Honeycomb board,Wood board,Rubber,Fabric,Leather,Textiles,Car interior,etc. |

| Standard Fitting Features | 1.Automatic adjustment of cutting speed 2.Secondary compensation for cuttingvacuum 3.Inductive safety protection device |

| 4.Automatic feeding platform 5.automatically optimizes nesting layouts |

| Other functions | Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed |

| Main components | 1. Automatic cutting bed 2. automatic feeding 3. air floatation table |

| Main Accessories | Motor | Guide Rail | Switch | Knife Drive | Conveyor Belt |

| Panasonic | HIWIN | DELIXI | maxon | German |

Advanced Knife Cutting Machine

Cutting VersatilityHigh Cutting Speed: With a cutting speed of 1.5 meters per second, it ensures rapid and efficient processing.Optimized Material Utilization: Equipped with intelligent algorithms, it automatically optimizes nesting layouts, achieving a material utilization rate of over 95%, reducing waste and cutting costs.Exceptional Productivity: Capable of producing up to 15,000 cut pieces per day, it meets the demands of large-scale production with ease.Why Choose the VCM Pro?Reduce Cutting Costs: Minimize expenses per product.Boost Productivity: Operate at high capacity with maximum efficiency.Save Materials: Achieve higher material utilization.Enhance OEE: Ensure optimal equipment effectiveness.Maximize Output: Optimize productivity per square meter.

Enhance Production Speed and Minimize Costs

Experience next-level efficiency with our Industry 4.0-compliant cutting solutions, designed to optimize production for any manufacturing model or Honeycomb cardboard, corrugated cardboard, cardboard box, cardboard box, card . Achieve unparalleled speed, precision, and cost-effectiveness, regardless of production volume, with our integrated marker-making, pattern-making, spreading, and cutting technology.

See It in Action

Send us your samples-we'll cover the postage and witness the cutting process and machine operation via live stream. Let us prove how we deliver excellence, innovation, and value.

Take the First Step Toward Efficiency

Contact us today to experience the future of cutting technology.

Efficient Cutting Workflow

Simple & Efficient Operation

Streamline your workflow with our advanced HT2024 cutting software:Design in Seconds: Create complex clothing templates in just 3 seconds with one click.Optimized Material Utilization: Powered by a vast database and intelligent algorithms, achieve automatic material layout with up to 95% utilization.Seamless Automation: Transfer layout files to the cutting machine with one click for precise automatic cutting and effortless transport to the receiving table.All this efficiency requires no more than two operators.

Comprehensive Support

We offer three operation tutorial options to suit your needs:On-site Installation & Training by professional engineers.24/7 Remote Guidance for installation and operation.Access to a 40GB Video Tutorial Library for complete learning flexibility.Efficiency Made Simple-Contact Us Today!

Our AdvantagesEmbrace the Future with HTCT

For over five years, HTCT has been at the forefront of revolutionizing the flexible material cutting industry, committed to enhancing production efficiency and empowering professionals worldwide. Today, we are proud to be among the industry's pioneers.

CNC Knife Cutting: The Future of Precision

In the era of Industry 4.0, CNC Knife cutting machines are transforming traditional methods. Compared to manual and laser cutting, CNC technology offers unparalleled precision, efficiency, and innovation-setting a new standard for the industry.

HTCT Cutting

Automatic operation that saves labor.

Intelligent layout ensures high material utilization.

Environmentally friendly blade cutting is precise and does not require heat.

Laser Cutting

Laser cutting can result in yellowing and scorching of the edges of material, which may require subsequent processing. Additionally, this method may lead to damage to the materials and produce a significant amount of smoke.

Manual Cutting

The precision of manual cutting techniques is significantly lacking, resulting in inefficient material layout and substantial waste. Additionally, manual cutting demands excessive labor and time, which undermines productivity and efficiency. It is imperative to adopt more advanced methods to address these shortcomings.Details and Sevice

All parts are from top-tier brands such as Omron, Delixi, Panasonic, etc., and enjoy a warranty of more than 3 years.

The high-strength integrated frame is designed to support loads of over 3 tons.

This high-efficiency vacuum pump boasts a maximum power output of 9 KW.

Additionally, it can achieve a negative pressure of up to -22 Kpa in the cutting area, enhancing its performance and versatility in various applications.The Panasonic servo motor is a robust component designed for cutting machines, featuring the capability to operate 4 to 5 motors simultaneously.

China Taiwan's HIWIN stainless steel guide rail features a non-slip design and is capable of achieving micrometer-level positioning accuracy.

All components are sourced from established international brands, including Delixi, Omron, Siemens, and Panasonic.

These components are recognized for their stability and durability, and they come with quality assurance.

1. The HTCT after-sales service team has more than 25 engineers.

2. There are 3 engineers at least to serve one agent/client, all of them can speak English.

3. We support a full user manual, using video and photos.

4. We support remote assistance to help you to install and use the software.

5. We support 7*24 hours of online guidance and service.

6. Our machine is with 3 years warranty, except for the felt, cutting tool, and knife blades, during this time, if there are any problems, we will change the new one for free by DHL, and for the cutting tool, we will repair for free within one year.

7. We promise to send out the replacement parts within 24 hours.

8. We will make a service group for you, including HTCT sales personnel, engineers, the sales manager, the sales director, and you (or your staff), If you have any problems, we will respond within 1 min.

9. HTCT software is a free upgrade for life.Factory ProfileShandong HTCT CNC Equipment Co., Ltd.

HTCT, established in 2019, is a factory with five years of extensive experience dedicated to the manufacturing, research, and development of advanced material-cutting machines. Our expertise in the field allows us to innovate and produce high-quality equipment that meets the diverse needs of the textile industry.

--The factory is situated in the Jinan High-Tech Zone and spans an area of 20,000 m². The product services offered include cutting for clothing fabrics, leather, multi-layer fabrics, home textiles, automotive interiors, advertising materials, and composite materials. The company operates as a provider and manufacturer of comprehensive cutting solutions for flexible materials.

--Currently, our team comprises 25 research and development engineers, 149 production technicians, 50 market service experts, and 31 overseas after-sales engineers. We provide product services to more than 80 countries and support approximately 1,750 customers globally, achieving an annual output value exceeding 50 million US dollars.

We are dedicated to delivering tailored product services that address the specific production needs of our clients.

Our goal is to assist in resolving production challenges effectively and efficiently.

>> China Heavy Duty Hydraulic Clamping Radial Drilling Machine (Z3063X20A)

>> FRP/GRP Cage Ladders

>> Taijia concrete rebar scanner locator detector price rebar scanner concrete rebar locator Detect the position

>> Amada Standard 835 CNC Bending Machine Lower Dies Press Brake Tooling

>> New Arrival 2022 Mini Handheld Neck Fan Portable Rechargeable Wearable Electric Usb Desk Stand Table Air Cooling Fans for Summer

>> 6mmx12mmx12FT Bungee Trampoline Cord

>> High Speed Low Noise Straight-Line Wire Drawing Machine-800 I-Turn Take-up Unit

>> constant tension control PVC, Pet, PE Film Laminating and Slitting Rewinding Machine

>> CE Certificate Smokeless Environmental-Friendly up to 2 Inch Hose Hydraulic Rubber Hose Cutting and Skiving Machine

>> Professional Spearfishing Scuba Diving 2 Pieces Men Camo 5mm Neoprene Thermal Customized Hoodie Wetsuit

>> Water Dispenser Spare Part ABS Plastic Cup Holder for Water Machine

>> 12V 2500 Lbs Electric Winch with Synthetic Rope for ATV off-Road Self-Rescue

>> 2-6 Bending Frame Butt Welding Machine Wire 2D Bending Machine

>> Custom Advertising Promotional Front PE Magnetic Car Sunshade Foldable and Car Window Sunshade Snow Sunshade

>> Steam Electric Heating Autoclave Tank for Rubber Seals Shoes Hoses Pipes Rubber Product Making Machinery

>> High Quality Stone Granite Construction Waste Spring Cone Crusher for Sale

>> Timeway CNC Vertical Machining Center Milling-Machine Center for Metal

>> Bozz 6.6ah 3W USA CREE LED 10000lux Mining Lamp (Kl5lm(B))

>> Good Quality Double Arms Furan Resin Sand Mixer Machine, Continuous Sand Mixer for Silicate

>> Automatic Factory Directly Cheap Price PU Injection Machine on Sale

>> Universal 100-240VAC 50/60Hz 2 USB Port Power Charger Pd Adapter with CE GS Safety Mark Coc Approval 5V 1A USB Charger 5V 2.5A 2.1A 2A Power Adapter

>> API Cementing Tools 7" 9 5/8" 13 3/8" Casing Float Shoe and Float Collar

>> Agricultural Machinery Grinding Machine Rice Thresher Machine

>> Topstar Servo Motor Injection Molding Machine

>> Recycled Pet Intrinsic Viscosity (IV) Improves Machine (SSP)

>> Easy To Operate Automatic Dried Fruit Snacks Raisins Prune Sachet Food Packing Packaging Machine With Weigher

>> Hotsale Module, Jacquard Part, Module for Electronic Module

>> UPS Battery 110~288VAC 1kVA 10kVA Uninterrupted Power Supply

>> Touch Screen Dental Equipment Portable X Ray Machine

>> Highly Recommended Automatic CNC Pipe Laser Cutting Automatic Feeding Loading Laser Cutting Machine