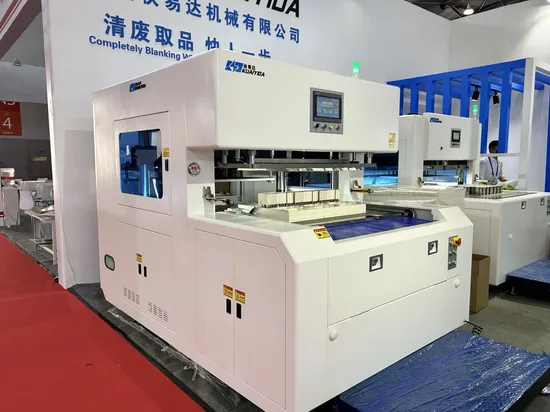

Automatic Waste Paper Blanking Separator Stripping Machine for Medicine Cigarette Box Cloth Label Tag Automatic Dismantle Machine

| US$25,000.00-50,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

KYD-1080A

Species

Blanking Machine

Imprinting Type

Platen

Placing Form of Template

Pins Type

Die Cutting Tool

Pins Type

Computerized

Computerized

Automatic Grade

Semi-Automatic

Application

Paper Packaging Materials

Max Material Stack Size

1080*780mm

Max Material Stack Height

80mm

Speed

5 Times/Min

Max Pressure

100 Bar

Air Consumption

2L/Min

Compressed Air

5-6 Bar

Power

380V/3 Phase/50Hz

Weight

3000 Kgs

Transport Package

Wooden Box Package

Specification

2650*1800*2000mm

Trademark

KUAIYIDA

Origin

China

HS Code

8441309000

Production Capacity

500 Set/Year

Product Description

KYD-1080A Row&Whole Automatic Stripping & Blanking MachineSamples

Whole Blanking Processing:

Row Blanking Processing:

Instruction

This automatic machine has a powerful waste removal function completely, which can achieve one pass fully remove all waste after die cutting for different specifications of box types, windows, and aircraft holes, and material waste edges of front and back stitching as long as they are within the size requirements of machine.

This machine have the high quality for removing the waste completely in one pass, with fast efficiency, simple operation, increasing user's production capacity.

Machine Advantage

1.pass to stripping & blanking waste area completely, High efficiency with Simple adjustment,Easy operation. Improve the user's production capacity greatly.

2.Not need the mould for different product size, with the honeycomb plate frame and pins to adapt to the changeable box shape. The lower pins support products area, the upper pins pressed on the waste area to remove the waste.

3.OEM Upper Working Panel for customer die cutting layout.

4.Row stripping & Full stripping function; can deal with more die cutting products.

5.Save Labor and Save tool cost and mould cost.

Technical Parameters:

| Model | KYD-1080A |

| Max Material Stack Size | 1080*780MM |

| Max Material Stack Height | 80MM |

| Max Pressure | 100 Bar |

| Speed | 5 times/min |

| Machine size | 2650*1800*2000mm |

| Weight | 3000 KGS |

| Power | 380V/3 phase/50HZ/10KW |

| Air Consumption | 2L/min |

| Compressed Air | 5-6 Bar |

Certifications

Packaging & Shipping

Company ProfileWENZHOU KUAIYIDA MACHINERY CO.,LTD

established in 2023, we focus on the development and innovation of blanking &stripping machine, provide efficiency products and reasonable stripping solution to every user. Company structure is scientific and reasonable with humanized management mechanism. Mature customer service system, technical engineers at any time provide after-sale consultation and arrangement installation and trouble shooting service for foreign customers

Our Workshop

Exhibition Photos

After Sales Service

Warranty period of the productThe product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways:

a. Send spare parts to the customer.

b. Remotely assist customers in maintenance.

c. Notify our agent company to send personnel to the customer's factory for maintenance.

d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.About transportation damageIn the process of product transportation, if product damage occurs, it is determined that our product packaging and reinforcement work is not in place, and our company will bear the corresponding losses.About machine maintenanceWe will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.Problems during useIf there is any problem in the process of using the product, the customer can directly call or send an email to our after-sales department (24-hour hotline). The personnel of our department will respond immediately and make a decision on the response measures within 24 hours

>> Corn/ Wheat Starch Milk Washing Hydrocyclone Starch Refining Equipment

>> Customized ISO9809-1 70L Ya Carbon Dioxide Gas Oxygen Equipment Autoclave CO2 Cylinder

>> 3D Wire Bending Machine Supermarket Trolley 3D Forming Machine

>> 65W 19V 3.42A Notebook PC Power Supply Power Adapter for Asus Zenbook

>> LMR195 Coaxial Cable Assembly with SMA-N Connectors for Antennas

>> Best Quality Hv Cable Cu/XLPE/CAS/PVC 38/66kv 38/69kv 64/110kv 76/132kv XLPE Insulated Underground Power Cable

>> 6020 4020 Fiber Laser Cutting Machine with High Speed

>> PP Plastic Sheets Rigid Plastic Sheets for Tank and Equipment

>> torque rheometer |2018 new model

>> Colourful Vinyl Tape Measure Flexible Sewing Tailor Tape for Clothes (OEM service)

>> 12js-130 Rock Picker Mounted Stone Provided Farm Machine Heavy Stone Picker

>> The Best Selling Food Grade Additives Aluminum Free Double-acting Baking Powder

>> Stylish Neoprene Dumbbell Set for Women′s Fitness Goals

>> Processing customized wear-resistant, anti-aging, anti-wear nylon floor stick for mine cableway

>> Paper Product Making Production Line Toilet Paper Making Machinery

>> Used Mobile Medical radiography system X Ray Equipment Second Hand Practix 100 plus X-Ray Machine

>> Cotton Garment Fabric Non Woven Waste Recycling Machine

>> Durable Lightweight Corduroy Bucket Bag Spring Cross Body Bag Vertical Casual Mini Tote Bag with Adjustable Shoulder Strap for Comfort

>> Rubber Automotive Timing Belt OEM Auto Spare Part

>> plate load tests (static plate) with standard plate 300mm/600mm

>> Modern TV Stand with Storage LED Wooden

>> Solar Adventure Rechargeable LED Camping Lantern of USB LED Flashlight Lamp Light

>> Tepps 280ap Stainless Steel Plastic Continuous Bag Packing Food Smart Sealer

>> Space Saving Wall Mounted Toilet Brush with Holder for Bathroom

>> Fresh Vegetable of China Fresh Ginger Wholesale Air Dried Ginger Price Per Kg

>> 8cm Plastic Sea Ball Blow Molding Making Machine

>> OEM/ODM Plus Size Oversized Tshirt Men Women Trending Heavyweight T-Shirt 100% Cotton Camiseta Casual Design Logo Printing Unisex Custom T Shirt

>> Factory Price F20 Series UV Laser Marking Machine

>> Toilet Plunger and Bowl Brush for Bathroom Cleaning

>> HC-H011C High performance weight meter body health analyzer body fat analyzer machine/fat analyzer scale/body composition analyz