Double Pistons Continuous Screen Changer Manufacturers

| US$5,500.00-43,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

GM-DP-L series

Automation

Automation

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Attribute to

Auxiliary Part of Plastic Recycling Machine

Function

Polymer Melt Filtration System

Raw Material

High Quality Alloy Steel

Drive Mode

Hydraulically

Controll System

Digital Electrical Controll System

Suitable Materials

Almost All Kind of Polymers

Transport Package

Sea Worthy Packaging

Specification

CE, SGS

Trademark

Gamch

Origin

Zhenzhou

HS Code

8421299090

Production Capacity

300 Sets/Year

Product Description

Specifications1,screen chnager 2, Leak-free mold 3,esay operation 4, reasonable price 5, CE,SGS approval

Our advantages

1, Senior technical engineer with more than 15 years of experience in the polymer filtration fields

2, Fully equipped with all needed fabricating machinery,guattantee the quality and the date of delivery of the products.

3,Customized design is welcome

4,Quick delivery time

5,OEM service is provided

6,Reliable and trustworthy service

Product Description

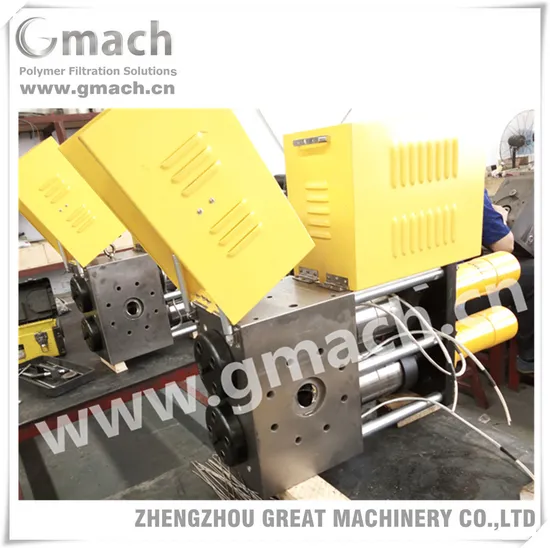

Double pistons continuous screen changer manufacturers

This GM-DP-L series Double pistons continuous screen changer manufacturers is consist of

The main body of the screen changer Hydraulic unit Electrical controlling pack(this part is optional choice by customers, the above picture shows two kind of controll system) This GM-DP-L series Large capacity continuous screen changer for polymer melt filtration for hot melt adhesive production machine is designed based on GM-DP-R series dual rods continuous screen changer , this kind of Double piston large capacity continuous screen changer enlarge the filtration area by instead the round breaker plates as the rods full of holes, and the filter screen is wrapped on the rods. And this kind of continuous screen changer now is widely used for the hot melt adhesive, high output plastic recycling machine.

After successful trials at Kunshan ,A ABS recycling factory, we have equiped two sets of the ABS recycling machine with this kind of double piston continuous screen changer with large capacity.Through the filtration process, The ABS flakes can be processed at a throughput rate of 1100kg/h. That is to say, this kind of large capacity screen changer can meet the high output recycling extrusion machine .

Characteristics of GM-DP-L series Double pistons continuous screen changer manufacturers

The filter screen is wrapped on each slide bearing bars full of small holes-the same function as the breaker plates "Continuous type" means operation of screen change without machine halt or disruption of melt flow. Equiped with air venting system Fit for almost all kinds of polymers It works well under the high pressure 400bar(40Mpa) not impact the high performance. The filtration screen area covers from 400cm² to 2500cm², depending on the size, fit for output range from 100kg/h to 4800kg/h.

Benifits of this kind of Large capacity continuous screen changer for polymer melt filtration Continuous operation Leak-free mold of operation Large filtration area meet the high output extrusion machine Customized design adapters venting groove discharge the gas mixed in the polymer melt Simply controll by a easy operated control handle Reasonable price and proved technology

Types

| Type | Screen D&A | Overall dimension (mm) | Heating power (KW)) | Output (kg/h) | ||||

| Screen diamension L*W (mm) | Filtration area (CM²) | L | W | H | L1 | |||

| GM-DP-L-100 | 251x80 | 200x2 | 220 | 200 | 320 | 810 | 3.5/4.7 | 450-1200 |

| GM-DP-L-120 | 314x100 | 314x2 | 250 | 220 | 360 | 970 | 5.0/7.2 | 800-1800 |

| GM-DP-L-155 | 408x130 | 530x2 | 320 | 270 | 450 | 1100 | 8.2/11.1 | 1000-2600 |

| GM-DP-L-175 | 471x180 | 846x2 | 370 | 310 | 480 | 1320 | 9.4/12.7 | 2300-4400 |

| GM-DP-L-195 | 533x190 | 1012x2 | 400 | 380 | 550 | 1470 | 10.2/13.8 | 2900-6000 |

| GM-DP-L-220 | 596x200 | 1192x2 | 440 | 410 | 590 | 1620 | 13/17.5 | 3900-10000 |

| Remark:The output rates depend on the individual extrusion process parameters. | ||||||||

>> China Factory Garden/Farm 2WD Walking Tractor Mini Small Rotary Tiller with 7.5HP Gasoline Engine Cultivador De Energí a

>> Hf-458t Thin-Wall Products High Speed Precision Injection Molding Machine

>> Modern Executive Desk Office Table Desk Director Computer Table Furniture Executive Office Table with Good Price

>> underground Straight Guide Aluminium Roller electrical straight cable roller

>> Gphq Hot Sale Zw Series External Vibrator with Copper Wire Winding

>> SHENGKE Simple Wrist Watch Bracelet K0059L Fancy Chic Girls Handwatch Women Watch Ladies SK Brand Watches

>> Perfume Online Wholesale and Retail Dubai Arabic Original Perfume Top Selling High Quality Fragrance Men Women Long Lasting Classic Scent Body Spray Erba Pura

>> EU Stock Amazon Top Sale Organic Goji Berry

>> Kids Sports Trampoline Indoor Fitness Safety Round Jumping Bed

>> SHENGKE Latest Starry Sky Face Design Watch Steel Mesh Band Milanese Strap Women Quartz Wrist Watch jam tangan

>> Smart Home Atmosphere Lights LED Hexagon Light APP Remote Control

>> PVC Auto Dosing Conveying System for Powder Pellet Granule Material

>> Rubber Flooring Tile Mat Brick Making Machine, Rubber Paver Tile Press Machine, Rubber Vulcanizing Press, Rubber Floor Vulcanizer, Rubber to Tile Machine

>> Si-3303 Si metal Si powder Si lump Metallurgy Materials Best Price

>> Large & Very Long Horizontal 1400x12000 6T 12m Length CNC Lathe

>> Open Mouth BOPP PP Paper Wpp Laminated Bag Waterproof Agricultral Feed and Seed Bag

>> Plastic Bottles Blow Molding Machine (TCY701D)

>> Universal High Quality 11kw Vertical Milling Machine Price X5040 CNC Metal Milling Machine

>> Gopro Hero11 Black Waterproof Action Camera with 5.3K60 Ultra HD Video, 27MP Photos, 1/1.9" Image Sensor, Live Streaming, Webcam

>> Gear Shift Lever Base D-MAX for ISUZU 8-98219761-0 (discount 2% off)

>> Factory Direct Laundry Dry Cleaner Clothes Oil Grease Remover Dry Stain Remover Textile From Oil

>> PE100 PE80 Water Well Flexible Black Pipe Blue Line

>> Customization Gear Steering Pump Water Pump Booster

>> Best-Selling High-Cost-Effective Lathe Cw6163 Series Large Heavy-Duty Horizontal Manual Lathe

>> Easy Operation 2td-S2 ODM OEM Custom 1200X1130X1300mm Working Size Agricultural Soil Tiller

>> 16mm Zj4116 Bench Drill Press Drilling Machine

>> Ulap Q1501 15.6 Inch FHD 256GB SSD Office Computer Laptop with Fingerprint

>> Gypsum Hollow Block Selling Machinery Gypsum Powder Machine From Dalu Factory Directly

>> Hot Selling Bulk Packing Produce Sliced Dehydrated Carrot Strips

>> Prefabricated Swimming Pool Enclosure Tempered Glass Sunrooms Aluminum Frame Polycarbonate Retractable Sunroom Roof