High Precision 500GSM-1600GSM Product Weight Range Needle Punching Line for Automotive Interiors Nonwoven

| US$700,000.00-2,000,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

YYL

Automatic Grade

Automatic

Certification

CE, ISO9001: 2000, GOST, UL(Advance Specified by Customer)

Customized

Customized

Condition

New

After-sales Service

Life Time

Width

up to 4000mm

Product Weight Range

500GSM-1600GSM

Type

Nonwoven Equipment

Supply Voltage

Customized

Color

Customized

Delivery Time

6-7 Months

Transport Package

Partial Packing with Wooden Cases

Trademark

YINGYANG

Origin

Changshu Jiangsu China

HS Code

8449009000

Production Capacity

Maximum 800kg/H

Product Description

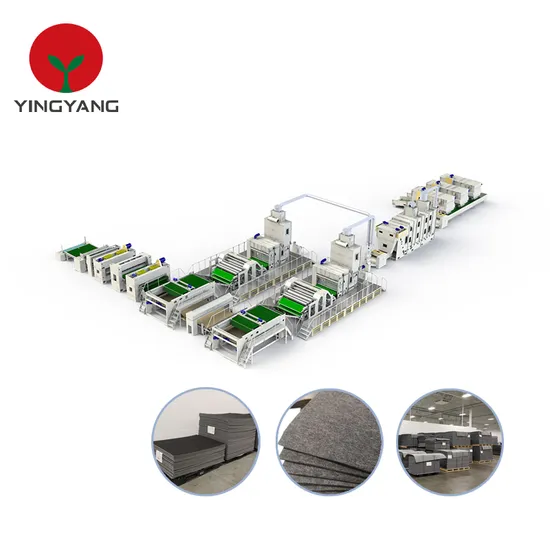

High Precision 500GSM-1600GSM Product Weight Range Needle Punching Line for Automotive Interiors NonwovenProduct Description

Function and Characteristics:

This line usually includes three sets of needle punching machines and it can make different kinds of needle punched product for automotive interior nonwovens, such as the automotive floor carpet, automtoive wheel arch liners, automotive rear deck lid liners, and so on.

High quality, High capacity, High efficiency, Energy saving, High Automatic, and Invironment friendly

Production process:

Bale opener→pre-opener→blending machine→main opener→(vibration feeder+ carding+ cross lapper)×2→batt feeder→needle punching machine*3→Winder&cutter Product Parameters

Main specification:

| product net width | up to 4000mm |

| product specification | 500gsm - 1600gsm |

| Material | 3-15 denier polyester and polypropylene fiber |

| Production capcaity | ≤800kg per hour |

Detailed Photos

All machines are new design and powder painting. All the main cylinders of carding machine are made from specialized armor plate and with our own special machining process. And all machining facilities and measuring instrument are high advanced imported from Japan and European countries. The enclosed structure design for carding machine highly improves the cleaning frequency. The special design for the pedestal and platorm of carding and feeder is very convenient for the machine maintenance.

| PET, PP fiber | |

| product width | ≤9500mm |

| product weight | ≤1000 gsm |

| capacity | up tp 1000kg/h |

| Main production line | |||

| Geotextile production line | Acoustic fiber board production line | Automotive interior nonwoven production line | Synthetic leather substrate production line |

| Thermal bonded wadding production line | Through -air bonded nonwoven production line | Spun-bonded nonwoven production line | Spun-laced nonwoven production line |

| Filter felt production line | Needle punched wipe production line | Scrubbing pad nonwoven production line | Comforter filling production line |

| Airlay felt nonwoven production line | Glass fiber production line | Jute felt needle punched production line | Geo-synthetic clay liners lamination production line |

Company Profile

Certifications

Packaging & Shipping

After Sales Service

FAQ

>> Ins Gift VIP Credit Card Packing Box Custom Sliding Drawer Envelope Card Packaging

>> Vmc550 Vmc650 Vmc850 Vmc1160 Vmc1270 Vmc1370 Vmc1890 Vmc1890 OEM ODM 3 Axis 4 5 Axis CNC Milling Machine Horizontal Vertical CNC Machining Center Bt40 Bt50 Vmc

>> Nadun Vt45 Precision CNC Vertical Turning Center with CE ISO Standard

>> Digital Human Anatomy System 3D Body Virtual Autopsy Table for School

>> Sephcare thermochromatic pigment

>> Three Station Injection Blow Moulding Machine

>> Four Wheel Mobile Lifting Platform with a Wide Operating Table Lift

>> Factory Price Automatic Signs Making CNC Bender Making Aluminum Profile Channel Letter Bending Machine

>> Reliable Heavy Duty Lifting Stage for Sturdy Industrial Performance

>> Automatic Center Pivot Irrigation System

>> Artificial Crafts Handmade Satin Ribbon Organza Rose Flowers for Garment

>> U-Stand Portable Whiteboard Magnetic Dry Erase Easel Height Adjustable 360 Rotating Flip Chart for Office

>> Parts for Manufacture of Semi-Conductor Device Glass Tube Do-41L

>> Frozen IQF 3 Ways Mixed Vegetables California Mixed Vegetables Blend with Cauliflower, Broccoli and Carrot with Wholesale Price

>> China Qunfeng CE, ISO, SGS Construction Machinery Brick Making Machine

>> Factory Price Woven Lanyard Polyester Custom Image Lanyard

>> Tdxz Flour Bran Silo Vibro Discharger Silo Bottom Vibration Unloader Discharger Bin Activator

>> Acemien PVC Glazed Trapezoid Roofing Sheet Plastic Tile Effective Rroduction Line Making Machine

>> Gfrp Fiberglass Tank or Vessel Filament Winding Machine, Production Line, Mandrel or Mold for Diameter DN2200, 2400, 2500, 2600, 2800, 3000, 3200, 3500, 3600mm

>> High-Volume Crushing Machines on Sale Advanced Grinding System for Efficient Biomass Grinding

>> B Series Fgg 304 2-30 Pin Self Locking Circular Push Pull Connectors

>> Ergonomic 2D Lumbar Support High Quality Custom Color Swivel Executive Mesh Office Chair

>> 300L Manufacturer Specially Designed Copper Core Flat Solar Panels

>> China Factory Horizontal Flat Bed Metal CNC Turning Lathe Machine

>> ODM Riha ABS Offer Standard Injection Molds Gear Mini Gears

>> OEM 5010315825 63782A High Quality Vacuum Brazed Aluminium Radiator used for Midlum truck

>> Fidget Educational Archeology Toys: Christmas Gift, Wholesale Magical Atlantis & Fossil Excavation Blind Box for Kids. (00389)

>> Jinmao Textile Machine High Speed High Precision Short Running In Long Life Spinning Machine BS JM1 EM2 gb 11# Series Ring Traveller

>> Air Type Label Remover for Beverage Water Cola Drink Bottles

>> Foshan Toye Supply New Low Price Dental Equipment Instrument Mounted Unit LED Sensor Light Dental Unit Chair