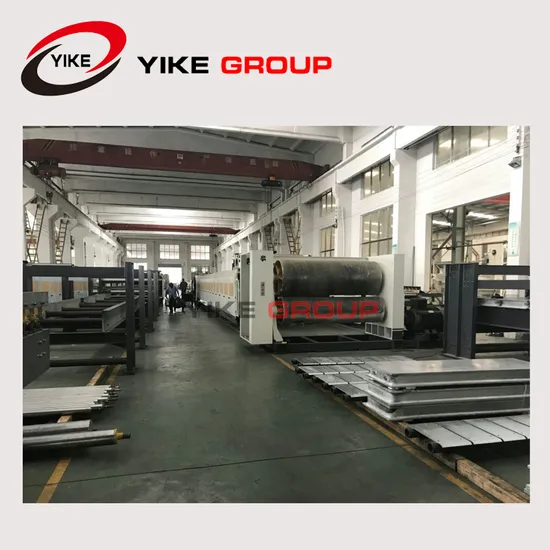

Corrugated Cardboard Production Line Double Facer Machine

| US$100,000.00-150,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

YIKE Double Facer Machine

Condition

New

Certification

RoHS, ISO 9001:2000, ISO 9001:2008, CE

Automation

Automatic

Suitable for

Paper, Corrugated Cardboard

Paper Thickness

3/5/7 Layers Cardboard

Item

Double Facer Machine

Size

1800/2200/2500

Type

Packaging Line

Name

Carton Box Making Machine

Function

Corrugated Box Machine

Usage

Making Corrugated Cardboard

OEM

Accept

Speed

150m/Min

Machinery Test

Provided

Application

Food, Beverage, Commodity, Medical, Chemical

Voltage

380V/415V/440V

Delivery Time

60 Days

Use for

3/5 Layers Line Width 1800-2500mm

Transport Package

Standard Packaging

Specification

Standard

Trademark

YIKE Group

Origin

China

HS Code

84413090

Production Capacity

30sets/Month

Product Description

SM-F type double facerStructural features:

★Heating plate surface by grinding treatment,hot plate width600mm,a total of 16 pieces heating plate,Cooling stereotypes Department 4 m.

Preheat board is made of contacts board, in accordance with the national standard of pressure container, enclosed the pressure container certificate and inspection certificate.

★Hot plate using the touch plate design structure. Plate movements using pneumatic spring-type structure.

★On both sides about conveyor belt deviation adjustment adopts automatic adjustment,2 sets of the conveyor belt tensioning system,one set is manual(fine tuning),the other is pneumatic adjustment(high speed).

★Thermal pipe heating plate temperature control points seven sections with temperature display.

★up cotton belt with double cylinder S cotton belt tensioning device.

★bottom cotton belt with s-shaped correction manually tensioning mechanism, structure simple and practical,under with manual fine-tuning.

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output.

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam.

Technical parameters:

1,MAX.effective width:2200mm

2,operation direction:left or right(according to customers factory)

3,highest Mechanical speed:150m/min

4,temperature requirement:160-200ºC

Roller diameter parameters: 1.up drive rubber roller diameter:¢700mm bottom drive rubber roller diameter: ¢400mm Wear rubber Outsourcing 2,Former follower with roller diameter:¢270mm After setting belt driven roller diameter:¢186mm

3,Pressure belt roller diameter: ¢70mm Shaping roller diameter:¢86mm

4,The belt tension roller diameter:¢130mm The roll diameter with detuning:¢124mm

5,Under the belt tension roller diameter:¢130mm Entrusted with the roll diameter under the belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated.

Power motors and electrical parameters: 1.Main drive motor power:30KW 380V 50Hz Continuous (S1) working standard 2,Hydraulic station motor power :2.2KW 380V 50Hz Continuous (S1) working standard

Mainly purchased parts, raw materials and origin:

| Name of main parts | Brands or place of origin | Material and type |

| Main skeleton | Tiangang or laigang | NO36Channel steel and NO16Beam |

| Heating plate | Tiangang or jigang | Q235BContainer board production |

| Main drive motor | Hebei hengshui | 30KWfrequency motor |

| Cotton belt | Shenyang | Thick cotton webbing10mm |

| traps | Beijing | Inverted bucket |

| contacts | France Schneide | |

| bearing | HRB,ZWZ,LYC | |

| Drive wallboard | Hebei | Gray cast ironHT250 |

| Pneumatic elements | Zhejiang sonorCSM | |

| Photoelectric switch | Korea Autonics | |

| Seat belt bearing | Zhejiang wuhuan |

>> China New Type keleier 4040 Ro Pressure Vessel 8040 Frp Ro Membrane Housing

>> Tct Circular Saw Blade for General Purpose Wood Cutting

>> 120cm Small Rice Harvester, Wheat Reaper, Gasoline Harvester, Paddy Reaper

>> China Factory High Quality Hot Sales Electric Motorcycles Designs Good Price for Sale

>> Fairly New Agriculture Machinery Combine Harvester Corn Kernel Wheat Machine for Sale

>> Factory Price Automatic Multi-Function Commercial Cookies Biscuit Cheese Sticks Machine

>> Packing Premade Bag Pouch Doypack Juice Cooking Oil Milk Coffee Machinery Automatic Water Sachet Shampoo Packaging Machine

>> Congo Red Thermal Stability Tester

>> 2023 Hot Sale High Precision Horizontal 5 Axis CNC Screw Milling Machine for Metal Tool

>> 5 Axis CNC Bridge Saw Support Dxf File Format

>> FACTORY SELL 6CT oil seal seat gasket 3933384 4205010 3913447 3938043 4205010 3926126

>> PP Honeycomb Sheet Pallet Sleeve Box for Home Appliances Industry

>> Customized 30′ ′ Carbon Detachable Handle Ice Fishing Rod

>> 1000PCS/Roll Square 40*40mm 50*50mm Bar Code Printable 8.2 MHz RF Security Tags EAS Anti Theft Stickers for Retail Stores

>> Customized High Precision Hardware Part

>> 20kHz 2000W Ultrasonic Welding Machine Piezoelectric Ultrasonic Generator Welding System

>> Pet Blowing Machine Including Blower

>> Factory Wholesale Price Aluminum Bottle Cap 4 Color Offset Printing Punching Machine Aluminum Cap Machine Bottles Caps Machines

>> Body Kit For Benz E Class W213 modified E63S Amg style Front car bumpers with grill

>> High Quality Steel Trailer Wheel Rim for 22.5X11.75

>> Extruder Fish Feed Pedigree Dog Food Making Dog Dry Food Packaging Machine

>> Folding Camping BBQ Grill Set Portable Barbecue Grill Stove 304 Stainless Steel Mini Pit For Camping Picnic BBQ Accessories

>> Aluminium Waterproof Motorized Opening Roofs aluminum pergola

>> ht225 Digital Concrete Test Hammer Price Digital Esclerometro

>> P2 Indoor LED Display Portable Standing LED Poster Advertising Panel Screen

>> ultrasonic fuel tank level sensor With Explosion Proof, water level gauge

>> Module spare parts 140XBP00400

>> Simulation Children Sport Archery Shoot Game Children Bow Arrow Set Kids Toy

>> Factory Direct Sale PP Polypropylene Granules for Boxes

>> Plastic Poultry Chicken Feeder and Drinker Making Machine