Automatic Pet Plastic Milk Bottle Making Machine

| Negotiable | 1 Set (MOQ) |

Basic Info.

Model NO.

ZQ-B600-4

Making Method of Parison

Injection Molding

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

After-sales Service

Engineers Available to Service Machinery Overseas

Number of Cavity

4 Cavities

Max.Output

5500-6000bph

Max Volume

600ml Bottles

Auto Systems

Fully Automatic

Delivery Date

30 Days

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Transport Package

General Packing

Specification

Max Volume: 600ml

Trademark

ZQ

Origin

Huangyan, China

HS Code

8477300000

Production Capacity

30 Sets/Month

Product Description

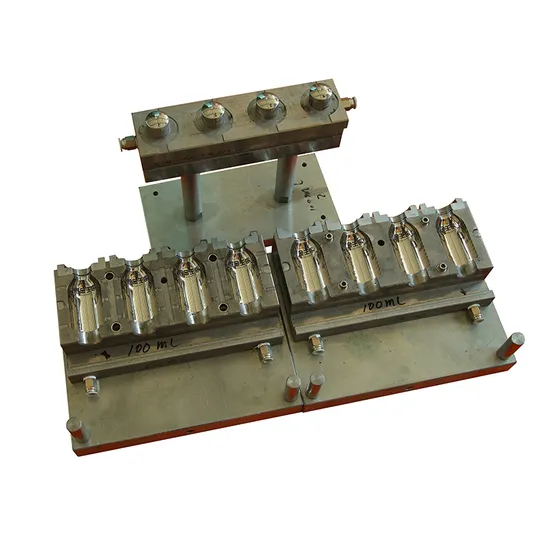

Automatic PET Plastic Milk Bottle Making Machine

5500-6000 bottles/hour, max 0.6L, 4 cavity

ZQ-B series full-automatic pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has one to two cavities and the maximum capacity of the products is 0.6L and 2.0L. It can blow bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

Pet Stretch Blow Moulding Machinery

1). High Automatization

2). High Intelligence: The machine can be controlled through touch screen and running status is shown on it.

3). High Quanlity: Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

4). High Speed: 2700BPH(2-cavity).

5). No Contamination: Closed production zone, good self-lubrication system avoid contamination.

6). Low Cost: Low consumption of electricity, air and water.

7). High Transparency: Easy maintenance, absolute safely, visual inspection, low noise.

Pet Stretch Blow Moulding Machinery,equipment information.

| TYPE | ITEM | ZQ-B600-2 | ZQ-B600-3 | ZQ-B600-4 | ZQ-B600-6 |

| CONTAINER | Number of cavity | 2 cavities | 3 cavities | 4 cavities | 6 cavities |

| Output | 2400-2700 pcs/hr | 3000-3300 pcs/hr | 5500-6000 pcs/hr | 7000-8000 pcs/hr | |

| Max. container volume | 0.6L | 0.6L | 0.6L | 0.6L | |

| Max. neck diameter | 38mm | 38mm | 38mm | 28-30mm | |

| Max. container diameter | 65mm | 65mm | 65mm | 60mm | |

| Max. container height | 230mm | 230mm | 230mm | 260mm | |

| ELECTRICAL SYSTEM | Number of lamp | 21pcs | 28pcs | 35pcs | 56pcs |

| Max. heating power | 21kw | 28kw | 32kw | 34kw | |

| Installation power | 24kw | 28kw | 32kw | 48kw | |

| Actual power consumption | 14kw | 18kw | 22kw | 24kw | |

| AIR SYSTEM | Operatating pressure | 7-9kg/cm² | 7-9kg/cm² | 7-9kg/cm² | 7-8kg/cm² |

| Low pressure consuming | 1000Ltr/min | 1200Ltr/min | 1600Ltr/min | 1600Ltr/min | |

| Blowing pressure | 25-35kg/cm² | 25-35kg/cm² | 25-35kg/cm² | 25-35kg/cm² | |

| High pressure consuming | 1500-2000 Ltr/min | 2000-2200 Ltr/min | 2200-2500 Ltr/min | 2000-2200 Ltr/min | |

| CHILLER WATER | Operating pressure | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² |

| Temperatuer | 10º C | 10º C | 10º C | 10º C | |

| Consuming | 5600kcal/hr | 5600kcal/hr | 5600kcal/hr | 8000kcal/hr | |

| Flow rater | 30Ltr/min | 30Ltr/min | 30Ltr/min | 88Ltr/min | |

| MACHINE | Machine dimension | 2.3x1.5x1.7(m) | 3.5x1.95x2.1(m) | 3.7x1.95x2.1(m) | 5.0x2.1x2.1(m) |

| Machine weight | 1.8ton | 3.6ton | 3.7ton | 5.0ton |

Note: The specifications are subject to change without notice for the further improvement.

Note: Custom production accepted. Any client idea tried.

>> China New Type keleier 4040 Ro Pressure Vessel 8040 Frp Ro Membrane Housing

>> Tct Circular Saw Blade for General Purpose Wood Cutting

>> 120cm Small Rice Harvester, Wheat Reaper, Gasoline Harvester, Paddy Reaper

>> China Factory High Quality Hot Sales Electric Motorcycles Designs Good Price for Sale

>> Fairly New Agriculture Machinery Combine Harvester Corn Kernel Wheat Machine for Sale

>> Factory Price Automatic Multi-Function Commercial Cookies Biscuit Cheese Sticks Machine

>> Packing Premade Bag Pouch Doypack Juice Cooking Oil Milk Coffee Machinery Automatic Water Sachet Shampoo Packaging Machine

>> Congo Red Thermal Stability Tester

>> 2023 Hot Sale High Precision Horizontal 5 Axis CNC Screw Milling Machine for Metal Tool

>> 5 Axis CNC Bridge Saw Support Dxf File Format

>> Wooden Cutlery Kitchen Utensil Wooden Kitchen Utensils Cookware Sets Cucharones Customized

>> Portable HDPE Horse Stable Horse Stall with Roofing 3X2.2m

>> Elite Scissor Lift Fruit Vegetable Lift Greenhouse Pipe Rail Trolleys for Picking

>> Stainless Steel Hygiene Corrosion Resistant Quick Connect Emulsifier Mixing Machine

>> Bedside Table Lamp with Melting Wax for Aromatherapy

>> Anti Water White Color Seaming Tape for Landscape Synthetic Turf

>> Na2s Flakes - Top-Notch Sodium Sulphide/Sulfide for Foreign Markets

>> Taijia Ferroscan Profometer. Multi Functional Rebar Detector Corrosion Detector rebar scanner locator detector

>> Vertical Wood Band Saw Cutting Machine Timber Sawmill Machinery

>> Computerized Rubber Polyretec Standard Wood Box Package Metal Tire Shredder

>> High Quality Digital Display UTM 1000KN Hydraulic Universal Testing Machines

>> High-Performance Injection Molding Machine for Flower Pot Production

>> Food Additives Sodium Erythorbate As Antioxidant, Preservative And Coloring Agent

>> Np-P10 Good Reviews New Trends Paper Cushion Making Machine

>> 3ml Transparent Aromatic Liquid Bottles Perfume Portable Cosmetic Packaging Oil Bottle Purification with Easy Open End Screw Metal Cap

>> Ortonbath Spain Fully Back to Wall Close Coupled Back to Wall Rimless Toilet with Cistern PP Soft Close Seat Cover 2PC Toilet Bowl

>> Automatic Hose Pipe Clamp Making Machine Price

>> Customized diesel engine small scale ore mine limestone wet dry used ball mill machine stone grinding gold ball mill for sale

>> Mini Centrifuge with Advanced Rotor Buckle Installation for Precision

>> Hotel Brief Style Grey Linen Bedding Set with King Queen All Size