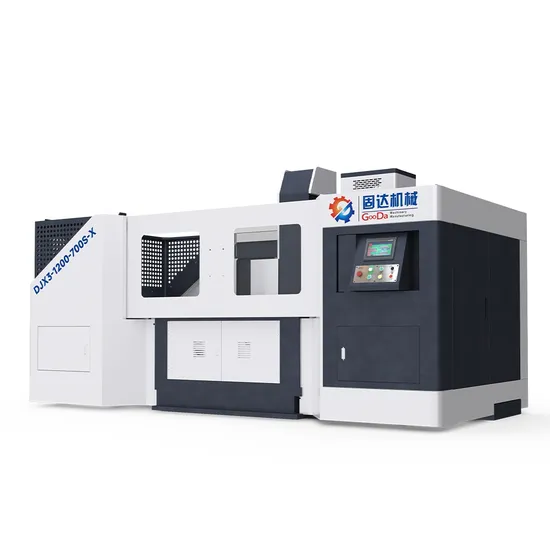

3 Axis Automatic CNC Chamfering Machine for Steel Plate & Mold Base Edges Milling

| US$6,699.00-7,299.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DJX3-1200-700S-X

Automatic

Automatic

Style

Desktop

Certification

GS, CE, ISO

Worktable Size

700*1350mm

Maximum Chamfer

C4

Processing Range

(20-300)*(150-700)*(150-1200)mm

Cutter Diameter

Φ90mm

Transport Package

Steel Box

Specification

Customized products

Trademark

GooDa

Origin

China

HS Code

8459619000

Production Capacity

500sets/Year

Packaging & Delivery

Package Size

3400.00cm * 1750.00cm * 1930.00cm

Package Gross Weight

3000.000kg

Product Description

Main FeaturesGooDa Chamfering Machine DJX3-S-X-Series is designed to maximize productivity by full-auto deburring. It adopts CNC touch screen, automatic measuring, automatic chamfering. The air floating magnetic chuck can easily rotate the workpiece at different angles.

This machine has excellent performance, high efficiency, and high reliability. It is suitable for metal processing industries such as mold steel, aluminum, and mold processing.

Main Functions

•Ra≤1.6, chamfer dimension: C1-C4

•Min. processing size (L*W*H): 150*150*20mm

•Max. processing size (L*W*H): 1400*800*300mm

•Designed to maximize productivity by automatically deburring

Three-head linked chamfering

Three-head linkage, triple efficiency! When chamfering horizontally, the upper and lower edges of the workpiece can be chamfered at the same time without flipping.

The upper spindle is equipped with a tool setting sensor, which can automatically measure the workpiece and record the tool path, improving chamfering efficiency and achieving safe and efficient production.

Air floating magnetic chuck

It enables easy movement of the workpiece by using air pressure to make the workpiece float, enhancing the anti-vibration ability of the worktable, reducing wear and ensuring accuracy.

CNC control system

Visual operating system, only need to input processing parameters to achieve high-performance motion control.

The operation is simple and convenient, with high stability, meeting the demand for efficient processing.

High-quality castings

The main components of this machine are made of high-quality castings, which are processed by CNC machine tools and subjected to stress relief annealing.

Full surrounding protective sheet metal

The protective sheet metal cover is designed to protect the important components of the machine, preventing metal debris from flying out and causing injury, as well as preventing cutting fluid from contaminating the ground, thus providing a safe and environmentally friendly machining environment.

It is equipped with automatic detection functions to enhance production efficiency.

Our team of experts is ready to help you find the machine most suitable for your processing needs. Get Expert Assistance Now! Product Parameters

| Model | DJX3-1200-700S | ||

| Category | Attribute | Value | Unit |

| Worktable | Worktable size | 700*1350 | mm |

| Max. load capacity | 2000 | KG | |

| Processing range | Number of control axes | 5 | / |

| Maximum chamfer | c4 | / | |

| Processing range | (20-300)*(150-700)*(150-1200) | mm | |

| Spindle | Spindle speed | 2825 | rpm |

| Spindle motor power | 0.75 | KW | |

| Cutter diameter | Φ90 | mm | |

| Feed speed | Servo motor | 1.0/1.0/1.0/1.0/1.5 | kw |

| Maximum rapid feed rate | 10 | mm/min | |

| Maximum cutting feed rate | 4 | mm/min | |

| Suction cup | Specifications | 700*1200 | mm |

| Tank | Capacity | 1.5 | L |

| Size & weight | Machine weight | About 3000 | KG |

| Machine size ( L*W*H ) | 3400*1750*1930 | mm | |

Applications

Company Profile

Factory Display

Certifications

FAQ

Q1. What is your minimum order quantity and warranty?

A1: MOQ is one set, and the warranty is 12 months.

Q2. What CNC system do you use?

A2: FANUC, SIEMENS, MISTSUBISHI, etc. It depends on your choice.

Q3. When is the delivery time?

A3: For conventional machines, we will deliver them within 30-45 working days after receiving your deposit; For special machines, the delivery time may be longer, and we will provide you with an updated timeline accordingly.

Q4. What is the packaging for the machines?

A4: Packaging: PE bag cover (inside), plywood box, and steel beam frame. Other packing methods are also available.

Q5. How can I select the most suitable machine?

A5: Please let us know your machining requirements or the machine size, and we can recommend the best model for you.

Alternatively, you can choose the exact model yourself. You can also provide us with the product drawings, and we will help you select the most appropriate machine.

Q6. What are your trade terms?

A6: FOB, CFR, CIF, or other terms are all acceptable.

Q7. What are your payment terms?

A7: We accept T/T with a 30% deposit when placing the order and the remaining 70% balance before shipment.

We also accept an irrevocable letter of credit (LC) at sight.

Production will begin once we receive the advance payment. When the machine is ready, we will send you pictures. After receiving the balance payment, we will proceed with the shipment.

Q8: Are you a manufacturer or a trading company?

A8: We are a combined manufacturing and trading company, specializing in the innovative development and production of machine tools, with extensive experience in global exports. We warmly welcome you to visit our factory.

Q9: Can you provide OEM services?

A9: Absolutely. We are happy to create a customized plan based on your requirements and offer the best service to meet your needs.

Q10: How can we receive training for the machines?

A10: You can send your team to our factory for free training, or we can arrange for one of our engineers to travel to your location for on-site training.

>> 20: 1 Stainless Implantation Contra Angle Handpiece

>> Small Plough Machine Crawler Cultivator Gasoline Annd Diesel Engine Mini Selfpropelled Power Tiller Rotary Cultivator Tiller

>> PP Fast Food Separating Plate Catering Tray Fruits Container Clamshell Box Cup Lid Blister Packing Forming Machine

>> Nougat Candy Plant / Machine

>> Multi Four Head Broderie Industrial Computerized Embroidery Machines with Flat Frames

>> Custom HVAC Air Duct G-Clamp For Flange

>> Coal briquette making-machine for coal powder/coke powder/gypsum powder

>> HONEYWELL FC-QPP-0002 C300 controller

>> Automatic Cotton Soft Tissue Folding Making Machine

>> Reusable PP Non-Woven Shopping Colorful Non-Woven Fabric Tote Bag

>> Vertical Benchtop Plastic Injection Molding Machine Price

>> Vertical Ring Die Sawdust Wood Pellet Mill / Bio-Energy Sawdust Pelletizer

>> Modern european designs leather wooden beds king queen size

>> Factory sale charcoal briquette mesh belt dryer machine for briquetting line

>> 320 Roll Label hot stamping Laminating Die Cutting Slitting and Rewinding Machine

>> Hot Sale Hydraulic CNC Copper Bus Bar Busbar Punching Bending Cutting Embossing Machine Processing Line Equipment

>> Building materials diamond hole expanded metal mesh optifix mesh

>> 6FT Pet Pine Needle Artificial Christmas Tree Decoration for Holiday Decoration Gift

>> Wholesale Durable Reusable Eco-friendly Metal Matte Rose Gold Double Blade Edge Men Safety Razor

>> DIN3356 Cast Steel Swing Check Valve

>> PCB Pogo Pine Terminal Design High-Speed Progressive Stamping Die Maker

>> 1000litre Vacuum High Speed Mixing Body Lotion Cream Conditioner Making Emulsifying Tank

>> Tonghui Th1963A Highest Annual Accuracy Tcal ± 5° C Digit Multimeter

>> 90011 Hydraulic Carbon Steel Material Hose Fittings Connectors

>> Factory Outlet L-Threonine Feed Grade 98.5% CAS 72-19-5 Nutrition Supplement L-Threonine

>> Biggest Manufacture Gypsum Drywall Production Line in China

>> 2021 new American style white frame PVC up and down window can be used as screen window

>> Factory Price Corrugated Box Making CNC Cutter Digital Industrial Cardboard Box Making Cutter Machine

>> Automatic Sliding Hermetic Door Hospital Galvanized Steel Automatic Door

>> Korea Revolax Deep Dermal Filler Hyaluronic Acid Dermal Filler for Nose Lips