ASTM B209 Alloy 3004 H14 Temper Kraft Paper Psmb Aluminum Coil/Stucco Embossed Sheet /Aluminum Jacketing /Polysurlyn Moisture Barrier Aluminum Jacketing

Basic Info.

Model NO.

1060/3003

Certification

ASTM

Technique

Coated

Grade

3000 Series

Temper

O - H112

Surface Treatment

Coated

Alloy

Non-alloy

Surface

1050 1060 1100 3003 Psmb

Transport Package

Standard Seaworthy Package

Trademark

Mesco steel

Origin

China

HS Code

7606122000

Production Capacity

2000

Product Description

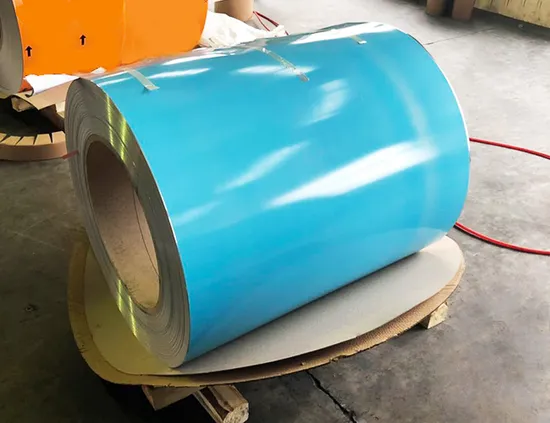

Product DescriptionPolysurlyn Laminated Aluminum Coil uses aluminum plate as raw material embossed with pattern design and compounding Polysurlyn as moisture-proof retarder. The film thickness is about 7 microns.It is firmly covered on the surface of aluminum coil board by high temperature and high pressure. Polysurlyn laminated aluminum coil is of moisture-proof, anticorrosive, wearable and durable. Another aluminum coil is aluminum coil with kraft paper.

Chemical Composition (%):

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al |

| 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | 0.10 | - | - | 0.05 | 0.15 |

| Alloy & Temper | Thickness (mm) | Tensile Strength (Mpa) | Elongation (%) |

| 3003-H14 | 1.0~1.2 | >=145~195 | >=2 |

| Item | Aluminum Plain Jacketing roll with Moisture Barrier |

| Aluminum coil Thickness | 0.12-0.2mm |

| Aluminum coil width | 500-1250mm |

| Polysurlyn thickness | 0.076mm |

| Color | Blue |

| Polysurlyn weight | 0.08kg/m2 |

| Corrosion Test | no visible change |

| Peeling off | not easy to be off |

Basic Mental | Aluminum coil or Stainless Steel coil |

Features of insulation aluminium cladding are:

1.Customized packaging solutions for extended shelf life.

2.Excellent barrier against moisture, oxygen & odour.

3.Excellent mechanical properties even at low thickness.

4.High burst strength and puncture resistant.

5,Light weight: Aluminum is about 1/3 weight of iron or steel, making it easier to handle and less expensive to ship.

6, Strong: the tensile strength can be 85-120Mpa, and can satisfy most of insulation jacketing needed.

7, Corrosion resistant: they do not rust.

8, Easy to fabricate & assemble.

Application

Aluminum cladding is recommended for use in all of the following insulation system applications:

Standard outdoor use on all pipe, vertical tank insulation systems up to 8 ft outer diameter, and all horizontal tanks. Indoor insulation system applications up to 8 ft outer diameter where increased damage resistance is desired. Company Profile

FAQ

Q: How long is your delivery time?

A: Our delivery time is typically within 7-15 days after receiving the deposit or L/C at sight. Please note that special designed products may require a longer lead time. Q: Do you provide samples? Is there an additional charge?

A: Certainly! We offer complimentary product samples. However, please note that the delivery fee will be covered by our customers. Q: What are your payment terms?

A: Our payment terms are as follows:

(1) 100% T/T

(2) 30% in advance, remaining balance before shipment. Q: How do you guarantee quality?

A: We ensure quality through the following measures:

- Always providing a pre-production sample before mass production.

- Always conducting a final inspection before shipment. Contact us

If you are interested in our products, please send us a specific inquiry. Include details such as the product name, thickness, width, quantity, coating, delivery time, destination port, and application. We will provide you with a customized offer that suits your needs.

>> Reliable Heavy Duty Lifting Stage for Sturdy Industrial Performance

>> Automatic Center Pivot Irrigation System

>> Steel Round Flat Bar and Carbon Steel Cold Drawn Steel Square Carbon Steel Round Bar 1215 12L14 4140 4135 8620 Sj235 C45 S45c C35 S35c

>> 5 LED Bulbs Air Turbine High Speed Handpiece Air Turbine 2hole 4hole

>> Double-Shaft Shredder Blade Plastic Film Household Waste Packing with Crusher Rotor Knife Claw Knife Crushing Knife

>> Tower Fabrication Machine FINCM CNC Transmission Tower Power Transmission Steel Shear Shearing Marking Punching Machine

>> Wind Power Hydraulic Pipe Flange for Foundation Ring

>> Hot Sale Fishing Net Machine with Single Knot Nylon/HDPE Braided Sports /Fishing Net

>> Auto Car Rear Bumper Step Pad For Toyota Tacoma 2012 - 2015 52162 - 04011

>> Ruipuhua Secondary Packaging System For Single Pouches Secondary Packaging Machine Flow Wrapper

>> PVC Soft Film Eco-Friendly Customized Plastic Film for Swimming Ring

>> Horizontal Small Flat Bed Metal Turning Bench Lathe Machine Center Slant Bed CNC Lathe Swiss Lathe

>> Wholesale Premium Kitchen Household Bamboo Cheese Board With Cutlery Set

>> Leaf A3 60cm Dtf Printer with XP600 I3200 Printheads for T-Shirt Hoodies Printing

>> 1ton Excavator Mini Excavator for Sale

>> Three Phase High Voltage Slip Ring AC Motor

>> Wholesale 5A Replica Online Store Genuine Real Leather Luxury Shoulder-Bag Ladies Fashion Lady Replicas Guangzhou Handbag Top Vintage Brand Designer Women Bags

>> Automatic toothbrush cartoning machine brush heads carton sealing machine

>> Emergency Strobe Light Vehicle Road Warning Light with Alarm for Truck Car Road

>> Concrete Brick Making Machinery Qt4-26high Technology Automatic Concrete Hollow Block Making Machine

>> Dual Spindle CNC Lathe Ty208ms with High-Precision C-Axis Indexing

>> Bcsports Dart Factory Supply 2ba Multi Color Soft Dart Tip

>> Hpe Dl380 G11 Rack Server

>> Wholesale High Quality Massage Table Messaging SPA Bed Message Therapy

>> Snowman Christmas Wooden Racket with Ball DIY Craft Toy Wooden Elastic Paddle Ball Game Rackets

>> Construction Waste Recycling Vertical Impact Crusher

>> R Series Belt Conveyor Helical Gearbox

>> Full Automatic Animal Poultry Cattle Feed Pelleting Equipment

>> Deals Low Price High Frequency Metal Heating Induction Heater (JL-15/25)

>> Intel E810-Xxvda2 Adapter 10/25GB Ethernet 2-Port SFP28 Smart Wired Wireless Pcie Pcie PCI SFP Server PC Internal External