LAG-S100 Ladle Slag Detection System (Eddy Current)

Product Details

Product Details

Product Description

Product DescriptionLAG-S100 Ladle Slag Detection System (Eddy Current)

Overview

The continuous casting ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of electromagnetic induction detection.

The meaning of slag detection

To achieve high output: In order to ensure the cleanliness of molten steel in the ladle, if we detect slag by eyes, we often close the ladle prematurely, so that it will reduce the yield of molten steel. However, if we use slag detection system, we can detect slag accurately and timely, so that the amount of residual steel is controlled at 1%-2% to achieve high output.

Improve the cleanliness of molten steel: The steelmaking slag gets into the tundish is the main reason that affects the cleanliness of finished steel. The use of the slag detection system can reduce the amount of steelmaking slag carried into the tundish to a very small amount, and can also reduce the defects on the slab surface at least 80%.

Avoid blockage of the nozzle: The steelmaking slag gets into the tundish is also the main reason for the blockage of the nozzle due to secondary oxidation. After using the slag detection system, the blockage of the nozzle can be greatly reduced.

The composition of the system

The slag detection system mainly consists of five parts: sensor, preamplifier, signal processing unit, central processing unit and platform control box.

System control flow chart

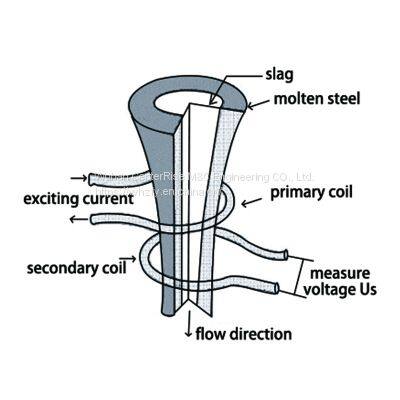

The working principle of the sensor

The sensor adopts the principle of electromagnetic induction for signal detection, and its typical structure is two concentric coils. When the primary coil is supplied with an intermediate frequency excitation current, due to the action of the magnetic field, an eddy current is generated in the steel flow, and the direction of the magnetic field is opposite to the direction of the magnetic field generated by the coil. Because the conductivity of slag is much lower than that of molten steel at high temperature (about 1/1000), the eddy currents generated in slag are much smaller than those generated in molten steel. In the process of pouring steel, all the molten steel flows out at the beginning of pouring. At the later stage of pouring, there will be steelmaking slag mixing out, which reduces the conductivity of the melt and enhances the electromagnetic field. This signal is measured by the secondary coil.

The principle of sensor construction

The primary coil and the secondary coil are isolated by high temperature resistant materials, and the coils are encapsulated in a flat ring made of special steel as a whole. Then two pairs of signal lines are drawn from the two-pole coil using a unique technical method, and sent to the secondary part.

The installation of the sensor

The sensor is installed in the ladle reference plate, coaxial with the ladle nozzle, and acts as a guide part for the ladle nozzle casing tube at the same time.

The technical Features

The ladle slag’s coil made of imported materials and installed at the bottom of the ladle as a guide component for the ladle nozzle can work normally in an environment of 900 °C for a long time, achieving no burning, no damage and good weak slag signal detection characteristics . The average service life of the sensor reaches more than 800 furnaces.

The signal connector of the ladle slag coil can meet the reliable connection of the microvolt level (1uV=10-6V) slag signal under the conditions of high temperature, high impedance and strong oxidation, and realize the repeated use of long-term zero impedance.

After the ladle slag coil works for a long time in a high temperature environment, changes in distributed parameter characteristics such as impedance cause signal drift. The system can automatically identify and compensate, which ensures the accuracy of system signal processing and alarming.

The function is complete, which can actually reflect various information of molten steel casting. It has various functions such as curve storage, status display, alarm display, output control, and information printing, etc., which can effectively meet the requirements of the production process.

The technical indexes

Sampling time:<10ms

System response time:<0.1s

Zero point average volatility:<4%

System detection value accuracy:<5% (duty ratio)

Slag volume alarm setting value: user-defined (recommended to use 20%)

Average sensor life: >800 furnaces

The working condition

Sensor use ambient temperature:<900℃

Operating temperature of secondary instrument:<40℃

Storage and transportation temperature of secondary instrument: -20℃-+70℃

The relative temperature used by the secondary instrument: at 25°C, the maximum is 95%

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact zero zero eight six one three nine nine five five eight eight five nine seven

>> Innovative Parallelogram Mounted Reversible Pivot Plow for Agricultural Work

>> 10 Inch 300W High Performance New Fashion Home Theater Active Heavy Subwoofer Active Speaker for Arbitrary Connection

>> Liquid Fertilizer Calcium Thiosulphate

>> Water Cooling ISO 9001 Approved Inte Aluminum Sheet Drill Machine

>> Factory galvanized steel stucco wire mesh with professional experience

>> Protect your cells from oxidative stress three-in-one 300ml Hydrogen Gas Inhalers 150ml Hydrogen Gas Inhalers

>> Cryo Body Shape Cryolipolysys 4 Handles 360 cryolipolyses Fat Cell Body Slimming Machine Criolipolisis

>> Women Ladies′ Rain Jacket Dust Coat with Mesh Lining Windbreaker

>> IP/WiFi Touch Screen System Smart Wireless Remote Control Video Doorphone Intercom

>> Package Lab Consumable PP Disposable Medical Supplies 1250UL 96 Wells Pipette

>> ABB CI871K01 PROFINET IO Communication Interface 3BSE056767R1

>> Automatic Soft Closing Sliding Door System Auto Soft Close Doors Car Electric Suction Door For Tesla Model 3 Model Y

>> Hot Sale Glass Spice Jars with Labels Bamboo 24 PCS 4 Oz Seasoning Containers Set Spice Containers with Shaker Lids for Kitchen

>> Decorative Bedroom Abstract Pattern Glass Mosaic Wall Mural

>> Peru Hot Sale High Quality Dq1504 150HP 4WD Four Wheel Agricultural Farm Tractor

>> Copy Marble Stone Look Tile Australia Style 800*800mm Porcelain Polished Fullbody Glazed Marble Ceramic Wall and Floor Tile for Hotel Supermaket Project

>> Hot Sale: Plastic Injection Blowing Molding Machine IBM Machine Manufacturer in China

>> Customized Gym Swimming Pool Metal Locker 9 Door Workshop Staff Clothing Storage School Steel Lockers for Changing Room

>> Hook Arm Lifting Garbage Truck Hydraulic System 20 Cbm Garbage Dump Truck for Sale

>> PLC Splitter 1x2 1x4 1x8 1x16 1X32 Fiber Optic SC UPC/APC Connector

>> Wholesale Vintage Custom Blank Unisex 100% Cotton Plain 6 Panel Outdoor Summer Sport Baseball Cap

>> High Speed 55ton Standard Hydraulic Injection Molding Machines for Sale

>> TF Types Of Rotameter Digital Rotameter Vertical Rotameter

>> Autoclavable Pharmaceutical Use Cleanroom Jumpsuit

>> Timing Chain Kit For Ford 5.4 Triton 5.4 Fortaleza 5.4 Expedition 5.4 FX4 5.4 F150 F250 MUSTANG 5.4 Kit De Tiempo ford 5.4

>> Korean Market Bedroom USB Car Mini Humidifier Office Ultrasonic Personal Humidifier Air Humidifier

>> Customized High Quality 8/9FT Nine-Ball Pool Table

>> High Speed Extrusion Blow Molding Machine Automatic Double Station 1 Liter 2L 5L 10L 20L Plastic Bottle Making Blower Machine

>> Cost Savings Large Power and 1390-Ec Work Area CO2 Laser Engraving Cutting Machine for Wood Sheets Acrylic Leather

>> The New Christmas Tree Embossed Refrigerator Sticker with The Same