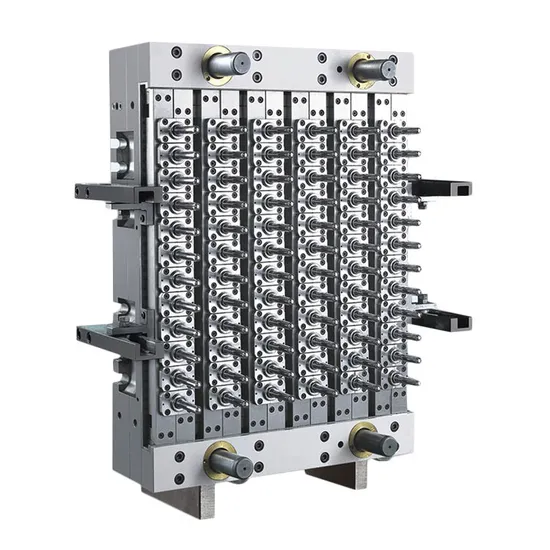

P20 Steel Advanced Pet Preform Mold Cycle Time 11-20s

Basic Info.

Model NO.

TH-S2

Material

Steel

Shaping Mode

Injection Mould

Runner System

Hot Runner

Cavity Quantity

48

Certification

CE

Customized

Customized

After-sales Service

Video Technical Support

Mold Plate

P20 Steel S136 Steel H13 Steel

Mold Life Time

3-5 Million Shots

Cycle Time

11-20s

After -Warranty Service

Online Support

Transport Package

Wooden Case

Specification

Customized

Trademark

pairui

Origin

China

Packaging & Delivery

Package Size

80.00cm * 30.00cm * 40.00cm

Package Gross Weight

200.000kg

Product Description

Product Name and Specialization: Unveiling excellence in our Plastic PET Preform Mold, masterfully crafted to create core, cavity, lip cavity, and neck thread with precision and finesse.

Core & Cavity Steel Composition:

Options include 2316# steel, S136 stainless steel, or tailored solutions based on your specific requirements, ensuring robust performance.

Mould Base & Standard Components:

Utilizing top-tier DME, HASCO, MISUMI, LKM standards, or custom creations with P20, 3CR13, 4CR13 materials, delivering unparalleled reliability.

Steel Hardness Specifications:

Base material features hardness of HRC30-35, ensuring durability and resilience.

Core and cavity materials exhibit an impressive hardness of HRC45-48, offering outstanding wear resistance.

Special parts boast superior hardness ranging from HRC60-62, epitomizing strength and longevity.

Plastic Material Compatibility:

Versatile with PET, PP, ABS, PC, AS, TRITAN, and more, facilitating diverse applications.

Cavity Number Flexibility:

Options include configurations such as 1*4, 1*6, 1*8, up to 1*48, catering to varied production demands.

Advanced Injection System:

Featuring Pneumatic Valve Gate with options for shut-off, free-cut, short tail, long tail, enriching your molding experience.

Efficient Ejector System:

Incorporates a Mould Slider + Stripper Plate Ejection, ensuring smooth and precise operations.

Remarkable Features of the PET Preform Mold:

1. Mold plates crafted from P20 steel with pre-hardening, core, cavity, and neck screw utilizing S136 high strength, anticorrosive stainless steel. Precision one-time processing ensures concentricity and compact mold structure.

2. Innovative spiral cooling for each core and cavity reduces cycle time, boosting efficiency and cutting costs. The pull plate design ensures reliable preform release, integrating slider, pushing plate, and ejection with self-lubricating copper alloys for low friction.

3. Individual cavity self-locking mechanism ensures precision, minimizing defects and simplifying disassembly.

4. Off-center adjustment system maintains preform thickness within 0.10mm. Double cone positioning enhances precision, preventing flash, irregularities, and defects.

5. Expertly designed preform molds using advanced software ensure optimal thickness and height, producing lightweight yet robust bottles.

6. Hot runner valve gate option eliminates preform tail cutting, reducing labor costs. Standard interchangeable components simplify maintenance.

7. Employing top Chinese or imported hot runner systems like Yudo/Mastip/Hasco, each cavity with independent temperature and heater control, preventing defects and lowering AA levels.

8. Comprehensive Customer Service: Enjoy a one-year free warranty and lifelong technical support, ensuring peace of mind.

| Mold | 24 48 72 cavity PET Preform Mold Can Be Customized |

| Preform Neck | 28mm,30mm |

| Preform Weight | Customized |

| Runner | Hot Runner |

| Core Material | S136 |

| Cavity Material | S136 |

| Screw Neck Material | S136 |

| Mold Base | 4CR13 Steel |

| Mold Life | 5 millions |

| scope of Application | Water bottle |

| Delivery time | 60-70 days |

------Our Distinguished Partners------

------Frequently Asked Questions (AFQ)------

Q1: What types of products do you offer?

A1: We provide a wide array of products including Sticker Labeling Machines, Shrink Sleeves Labeling Machines, Shrink Wrapping Machines, Injection Molding Machines, Blowing Machines, Filling Machines, Packaging Machines, and various Plastic Products.

Q2: How can you submit your inquiry?

A2: Reach out to us effortlessly through email, phone call, fax, or instant messaging platforms such as Trade Manager, WhatsApp, or Skype. Share your inquiry, and we'll be delighted to assist you.

Q3: How do I select the right machine for my needs?

A3: Share your specific requirements with us, and our team of experts will provide you with tailored advice to help you make an informed decision.

Q4: Is technical support available after purchasing your machine?

A4: Absolutely! We offer comprehensive video technical support and online assistance to ensure seamless operation and satisfaction.

- Should you require, we can arrange for our skilled technicians to travel to your facility. They will provide hands-on guidance and training for installation and maintenance of the machine.

>> Wholesale Summer Men′s Short Sleeve Shirts High Quality Running Workout T Shirt Custom Gym Fitness T-Shirts

>> Iron Casting Parts CNC Machinery Service Lifting Bracket Crane Machinery Parts

>> Meat Thermometer Digital Food Thermometer Waterproof Ultra-Fast Instant Read Meat Thermometer for Grill

>> Foot Type Grain Rice Wheat Pedal Type Thresher Machine Price

>> Thermal Break Polyimide Bars Mould

>> China Exports Fresh Vegetables Naturally Grown Garlic Fresh Garlic in Bulk Wholesale

>> 130L Bowl Movable Double Speed Spiral Four Mixer Dough Kneading Machine

>> Custom print China factory ice cream popsicle food grade aluminum foil plastic sachet back side seal frozen food packaging bag

>> Commercial herb, fruit and vegetable drying machine fruit dryer machine

>> Machining Non-Standard Custom Screw Lift Worm Gear Worm Shaft

>> Five Axis CNC Flame Pipe Cutting and Profiling Station (Roller-bed type)

>> Hot Sale Germany Plug Wall Socket with 2 USB Ports Travel Adapter Plug

>> Paddy Cutter Harvest Machine Rice Wheat Harvester Combine Machine Price Agriculture Harvesting Machinery

>> Custom Logo Print Recycled Brown White Kraft Shopping Food Packaging Paper Bag Handles with Your Own Logo

>> Mat for Egg Farm Chicken Poultry Laying Hen Nest Mat

>> Htjy-100A100kv Automatic Insulating Oil Breakdown Voltage Test Kit Insulation Oil Dielectric Strength Test Set Transformer Oil Bdv Tester

>> 4K 8K 2.0 2.1 HDMI Cable Metal High Definition 60Hz 120Hz 48gbps Certified Ultra High Speed TV Compuer Projector Laptop Set-Top Box Monitor Connection Cable

>> Multi-Brand RF Remote Control for Automatic Gate Opener

>> High Shear Food Emulsion Pump Milk Beverage

>> Factory Wholesale Cheap Price High Speed 100% Full Capacity 8GB 16GB 32GB 64GB Class 10 TF Mico Memory SD Card for Mobile Phone

>> Sanki 1m3 Cube Cylinder Portable Skid with suction Pump 50-80L/Min Flow Rate Flow Meter Fuel Dispenser Mini Mobile Fuel Station

>> Timing Chain Guide for Fiat Automotive Timing Rail TR3002

>> Industry Workshop Turnover Detachable Storage Stack Racking Stillage for Warehouse Rack

>> Anon China New Power Engine Mini Garden Tractor Tiller

>> Computer Control Medium Speed Dry Laminating Machine with Glue

>> 5s High Quality Vertical Turret Milling Machine Z-Axis Automatic Lifting (NT40 spindle)

>> Rotary BOPP hot melt labeling machine / label making machine for round bottle

>> Kid or Baby Plate

>> Wholesale Biodegradable 16oz Plastic Bowl Set Cereal fiber Food Rice 12cm Cutlery Dinner fiber Salad Wheat Straw Bowl

>> Pink Kitchen Multi-Functional Salad Utensils Vegetable Chopper Carrot Potato Manual Shredder Cook Vegetable Tools Fruit Cutters