Butadiene Rubber Br9000 for Tyre Manufacturing

| Negotiable | 20 Bags (MOQ) |

Basic Info.

Model NO.

Butadiene Rubber BR9000

Appearance

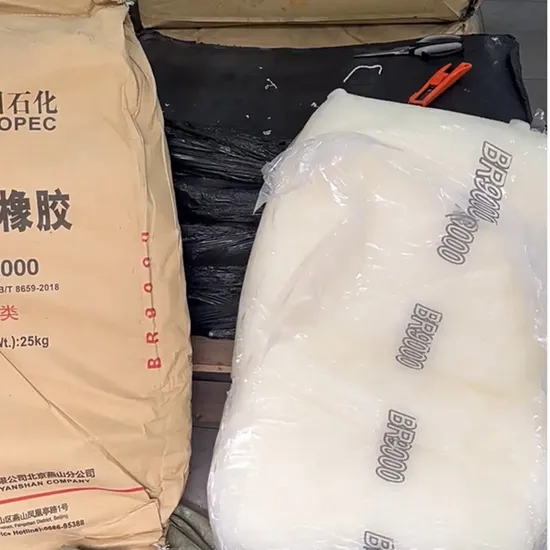

Light Colour Translucent Lump

Form

Lump

Shelf Life

2 Years

Output

100000 Ton/Year

Harbor

Qingdao/Shanghai

Product Name

Cis-1 4-Polybutadiene Rubber

Transport Package

Plastic Woven Bag with PE Liner

Specification

25kg/Bag

Trademark

LW

Origin

China

Production Capacity

100000 Ton/Year

Product Description

Product DescriptionDescriptions

Cis-1, 4-polybutadiene rubber (butadiene rubber) is a light-colored translucent lump and does not contain coked particles, mechanical impurities and oil stains.

Specifications

| Items | Standard | Test Result | Test Method |

| Appearance | Light color and translucent, primary shape is lump, does not contain coked particles, mechanical impurities and oil stains | Light color and translucent, primary shape is lump, does not contain coked particles, mechanical impurities and oil stains | Visual inspection |

| Volatile matter, % | ≤0.50 | 0.36 | GB/T 24131.1-2018 |

| Ash, % | ≤0.20 | 0.02 | GB/T 4498.1-2013 |

| Raw mooney, ML(1+4)100ºC | 45±4 | 44 | GB/T 1232.1-2016 |

| Compound Mooney, ML(1+4)100ºC | ≤65 | 50 | GB/T 1232.1-2016 |

| Tensile stress at 300% 145ºC, 25min, MPa | 7.0-12.0 | 9.3 | GB/T 528-2009 |

| Tensile stress at 300% 145ºC, 35min, MPa | 8.0-13.0 | 9.9 | GB/T 528-2009 |

| Tensile stress at 300% 145ºC, 50min, MPa | 8.0-13.0 | 10.0 | GB/T 528-2009 |

| Tensile strength 145ºC, 35min, MPa | ≥13.2 | 15.4 | GB/T 528-2009 |

| Elongation at break 145ºC, 35min, % | ≥330 | 420 | GB/T 528-2009 |

| MH/dN.m(160ºC,25mim) | Report value | 13.5 | GB/T 25268-2010 |

| ML/dN.m(160ºC,25mim) | Report value | 2.0 | GB/T 25268-2010 |

| ts1/min(160ºC,25mim) | Report value | 2.6 | GB/T 25268-2010 |

| t′c(50)/min(160ºC,25mim) | Report value | 5.2 | GB/T 25268-2010 |

| t′c(90)/min(160ºC,25mim) | Report value | 9.0 | GB/T 25268-2010 |

Butadiene rubber (Cis-1, 4-polybutadiene rubber) has the characteristics of high elasticity, low temperature resistance, wear resistance, flexural resistance, aging resistance, water resistance and low hysteretic loss and heating, mainly used in tire manufacturing, rubber shoes, tape, rubber plate, rubber hose and other rubber products industry. Butadiene rubber can be used alone or mixed with other rubber types to improve the performance of other rubber types.

Packaging

1. Packing in net 25KG per bag.

2. The storage should be in rows and stacks, and maintain a certain row spacing, stacking height is not more than 10 bags. It should be placed in a room temperature, ventilated, clean and dry warehouse, and it is strictly prohibited to stack in the open air.

3. Should prevent direct sunlight and rain soaking, transport vehicles should be clean, to avoid packaging bag damage and debris mixed.

Company Profile

Limwell New Material Tech.

In 2013, Shanghai Limwell New Material Tech. Co., Ltd. started the operation in Shanghai, China.

Limwell is an exportoriented comprehensive company, dedicating efforts mainly on the manufacturing and trading of rubber additives and tyre specific materials. Our manufacturing bases are in Shan-dong and Zhe-jiang provinces of China. In addition to that, we have also built partnership with a number of China local plants to enrich our product family.

Our Products include processing additives, anti-ozone waxes, masterbatches, resins, peroxides, flameretarders, and a wide spectrum of other materieals used in tyre and rubber products. With the belief in mind to provide both trusted product quality and outstanding sales service, we have become the stable supplier for a great number of tyre and rubber products plants all around the world.

We uphold the concept ''quality goes first, services upmost, human oriented and sustainable development'', and we're willing to be the best fit partner on your way to success!

Shanghai Office

Our Plant

One of our plants is located in the Zheshang Science and Technology Park in Jiashan, Zhejiang. This plant is at the center of prosperous Jiangsu Zhejiang Shanghai economic zone, and has achieved fasr and sustainable growth since the establishment due to strong market demand and our outstanding research and quality control capabilities.

This plant can provide high quality masterbatches, homoginizer, vulcanizer, scorch retarder and several other rubber processing additives. In 2014, we paseed ISO9001 and ISO14001 certificate audit. In 2016, we passed the TS16949 Quality System and OGSAS 18001 certificate audit.

In the last development procedure, we have also paid attention to operate in a sustainable and environment friendly manner, strictly adhering to the national and local environment protection regulations.

>> Rubber Product Making Machinery 1/8-1.1/2′′ 6-38mm Hydraulic Hose Pressing Machine AC Crimping Tool Price

>> Factory Customized Advanced Sony Imx415 8MP 4K Ultra HD Super Definition&High Frame Rate USB Camera Module

>> Winter Autumn Orthopedic Shoes for Kids with Orthotic Insole

>> Best Shipping Agent Service to Thailand

>> IP65waterproof LED Split Solar Street Light with Remote Control Solar Street Light High Lumen for Road Application

>> Educational Training Equipment Flat Panel Smart Interactive Whiteboard

>> Automatic Servo Control Hot Foil Stamping Machine JXC-75

>> Planning The Runner System Layout

>> World Brand 88HP Paddy Bean Wheat Combine Harvester for Sale

>> Customized High Speed Fabric Ultrasonic Garment Welding Machine

>> Carding Wire Used for Card Clothing

>> LTS726H 26000kg Single Drum Roller (Single Drive)

>> Opfd-1450 Factory Direct High Efficiency and Energy Saving Embossing Tissue Folding Machine

>> Sclerometer Concrete Ultrasonic Rebound Hammer Ultrasonic Pulse Velocity Tester hot sale

>> Lycra Swimsuit Vacation Wetsuit Long Sleeves Long Pants Sun Protection Large Size

>> Hot Selling Skmei 1815 Muslim Qibla Watch Gold Digital Wristwatch Waterproof 50 Meters for Men

>> Pet Support Nonwoven Fabric for Water Filter

>> HBQZ China Factory Produce Hydraulic Foldable Crane Machine Price (SQ880ZB8)

>> Garage Fixture Light Beauty Salon Hair Salon T5 LED Hexagon Lighting

>> Modern fronts patio entry sliding glass for home aluminum folding accordion door

>> 7 6 fishing Wholesale 5-7 section carbon fiber hot sale boat trolling genuine Pesca big Sea fishing rod continental 3m

>> Powder Coated Aluminum Raised Expanded Metal Mesh for Building Facade

>> Wholesale Price CS Bonnet For BMW 2 Series F20 F22 F87 M Series M2 M2C Style Aluminum CS Front Hood Engine Cover Hood

>> LED 1500W Smoke Fog Bubble Machine Bubble Smoke Machine Fog Bubbles Blower for Wedding Party Stage Event Concert Hot Sale

>> Quality Customized Men′s and Womens Outdoor Polar Fleece Zipper Jacket

>> J-BRAID 8 GRAND Braided Fishing Line monofilament Superline 150M Super Strong High Performance Lines

>> 15t Construction Machinery Wheeled Diggers Mini Wheel Excavator

>> Manual Vial Crimper 8mm 13mm 20mm Medical Vial Capping Machine

>> Hot Sale High Purity Graphite Material 99.9% Extruded Graphite Rod

>> Customized PU Leather Cosmetic Bag Female Large-Capacity Portable Makeup Organizer Toiletry Bag