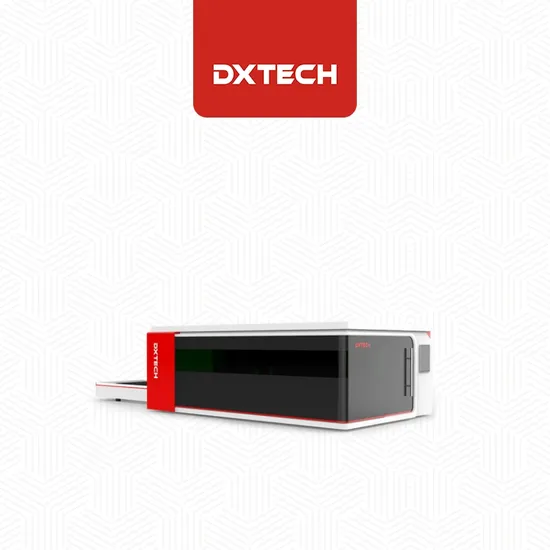

3015 Automatic Full Cover Stainless Steel Fiber Laser Cutter Fiber Laser Cutting Machine with Protection Cover

| US$30,000.00-55,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

DXTECH-1530SL

Application

Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Free Electron Laser

Laser Technology

Laser Control Fault Cutting

Laser Power

1-3kw

Wortable Size

1515X3030mm

Laser Source

Raycus, Max, Ipg Optional

Table Bearing Capacity

800kg

Gantry

Avaition Grade Aluminum

Transmission

Hiwin Guide Rails

Structure

Sheet Welded Bed

Motor

Inovance

Laser Head

Ospri

Control System

Weihong

Transport Package

3 Layers

Specification

4000KG

Trademark

DXTECH

Origin

Jinan, Shandong Province

HS Code

8456110090

Production Capacity

100 Sets/Month

Product Description

3000W 3015 Fiber Laser Cutting Machine for Sheet Metal Cutting 1500W Aluminum Carbon Steel Laser Cutting Machine Introduction

The DXTECH laser cutting machine with a closed exchange platform is an ideal solution for sheet metal cutting businesses that prioritize both high work efficiency and environmental protection. This machine is equipped with a fast exchange table that allows for simultaneous loading and unloading, as well as an enclosed cover that prevents smoke generated during the cutting process from being released into the air. In addition, all components and parts are made of high-quality Chinese products, ensuring reliable operation and a high cost-performance ratio.

Features

1. This machine has been certified by several international quality inspection systems, such as CE, FDA, UL, and ISO9000, ensuring that it meets the highest standards of quality and safety.

2. Equipped with an exchange worktable, this machine can continue cutting material while the operator unloads finished parts and loads new materials onto the other table. This feature reduces downtime between cuts and increases overall productivity.

3. The tube welded structure of this machine offers numerous advantages, including rigidity, stability, deformation resistance, easy maintenance, and high precision, among others.

4. With its fast speed and high efficiency, this machine can cut the most commonly used metal sheets, including steel, aluminum, copper, and more.

Machine Details

Major Parameters

| Model | DXTECH-1530SL | DXTECH-1540SL | DXTECH-2040SL |

| Working area (mm) | 1500*3000mm | 1500*4000mm | 2000*4000mm |

| Positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

| Maximum speed | 100M/min | 100M/min | 100M/min |

| Max. acceleration | 1.2G | 1.2G | 1.2G |

| Laser power | 1kw - 3kw | 1kw - 3kw | 1kw - 3kw |

| Laser | Multiple options | Multiple options | Multiple options |

| X-axis motor power | 850W | 850W | 850W |

| Y-axis motor power | 1300W*2 | 1300W*2 | 1300W*2 |

| Z-axis motor power | 400W | 400W | 400W |

Cutting Thickness of Different Laser Powers

Cutting Samples and Applications

The fully enclosed fiber laser cutting machines with exchange table are particularly effective at cutting metals because of the high energy density of the laser beam, which enables the machine to cut through thick metal sheets quickly and accurately. They are also able to cut intricate shapes and designs with high precision on stainless steel, carbon steel, aluminum, copper, brass, galvanized steel, titanium, and other alloys. Fiber laser cutting machines are versatile and can be used in various industries that require precision cutting of metals and non-metallic materials:

1. Manufacturing: Fiber laser cutting machines are widely used in the manufacturing industry to produce parts and components for various products.

2. Automotive: Cut metal parts for vehicles, including body parts, frames, and exhaust systems.

3. Aerospace: Cut metal parts for aircraft, including structural components, engine parts, and landing gear.

4. Architecture: Cut metal sheets and other materials to create decorative and functional architectural elements such as railings, staircases, and facades.

5. Electronics: Cut precision components for electronic devices such as smartphones, computers, and other consumer electronics.

6. Medical: Produce medical devices and implants, including surgical instruments and prosthetics.

Quality Inspection Before Delivery

Packing and Delivery

Improved packaging: Three layers--- -The innermost layer is the EPE pearl cotton film package; -The middle layer is wrapped up with environmental protection material ; -And the outermost layer is winding up with PE stretch film. They're very environmentally friendly. If you need a wooden box, we will make a fumigation-free wooden package outside the machine.

Why Choose DXTECH?

Company Scene

Certifications

After-sales Services

Global Customers

Partners

Payment Methods

>> CPU 6 Pin To 8 pin Graphics Video Card PCI Express Power Splitter Cable 6Pin Female Double 8Pin Male

>> 99.99% X-ray Lead Plate Roll / Coil / Strip 0.5mm 1mm 1.5mm 2mm 3mm 4mm 5mm Lead Sheet Roll

>> Huida Automatic Hydraulic Scrap Copper Steel Waste Metal Recycling Baler Baling Press Machine

>> Fashion Custom Logo Luxury Thick Frame Oversized Square Women Men Handmade Acetate Designer Sunglasses

>> Stainless Steel Rustproof No Drilling 2 in 1 Sink Caddy Sponge Holder for Kitchen Organizer

>> Electric New Winkko Color Box 2.0kg Garden Tools Cordless Sweeper

>> Cotton Kitchen Towel Waffle Hand Towel Large Bath Towel Microfiber Face Towel

>> 20T/30T Pull out Anchor Tester Rebar pull out test machine for sale

>> Agricultural Cultivator Parts Plough Disc Harrow Blade

>> Sc200/200 Passenger Material Construction Hoist Building Lift Architectural Single Cage Construction Elevator

>> Eco-Friendly Materials EVA Foam Sheets for School Education Crafts

>> Professional Boxing Training Gloves Custom Design real leather Boxing Gloves Cheap Leather Boxing Gloves equipment

>> Double Loop Wire-O Binding for Stationery Supplies

>> New Arrival! FDA Certification 200 Millions Shots 4 Wavelengths Skin Rejuvenation Diode Laser Hair Removal Machine by Clinic Salon Equipment Factory Price

>> Factory Price Baby Basket Portable Universal Children′s Car Safety Seat

>> 200mm 250mm 300mm PP PVC Rolled Type Round Cooling Tower Fill Media

>> SNAT607MCI ABB module supply

>> Custom Embossed Badges 2D / 3D Logo PU/Leather/Rubber/Silicone/Soft PVC Patch for Clothing/Clothes/Bag

>> 10 Tray Electric Convection Oven with 3 Deck Rack&Digital Panel

>> Galvanized Pipe Seamless Steel Pipe Galvanized Stainless Steel Pipe Steel Tube

>> Bison China 5HP 6.5HP Gx160 Mini Poker Concrete Vibrator with Hose

>> Libite Cordless Rotary Mini Hammer

>> Automatic Fruit Coconut Peeling Machine for Papaya Pumpkin Cantaloupe

>> Rear window glass Lift Support shocks struts for Chevrolet S10 Blazer 1983-1994

>> OEM/ODM Metal Sand Casting Heavy Duty Sewer Manhole Covers C250 D400 Ductile Iron Manhole Covers

>> Conector Coaxial del cable rg59 RG6 lmr195 de 90 grados en la esquina recta del enchufe de SHV

>> 8t Rating Bow Shackle for Offroad 4X4 Recovery

>> 1000kg-2500kg/H Hot Sale Woodworking Oak Beech Pine Wood Sawdust Alfalfa Pellet Machine Hay Pellet Machine for Fire Pelets

>> Disposable Balloon Helium Tank 22.3L Low Pressure Steel Helium Cylinder

>> Top Quality PE LDPE EVA and Soft Rigid Pulverizer Plastic Grinder Machine