Precision Crankshaft Grinder for Advanced Metal Surface Finishing

| US$68,000.00-70,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

520CNC Grinding Machine

Type

Surface Grinding Machine

Processing Object

Hardware Mold Accessories

Abrasives

Grinding Wheel

Controlling Mode

CNC

Automatic Grade

Automatic

Cylindrical Grinder Type

Surface Grinding Machine

Precision

High Precision

Certification

SGS

Condition

New

System

Syntec CNC

Name

Grinding Machine

Usage

Metal Surface Grinding

Machine Name

CNC Grinding Machine

Transport Package

Box

Specification

1.8*1.8*1.9M

Trademark

CYMT

Origin

Dongguan

HS Code

8460292

Production Capacity

500

Product Description

Product DescriptionThe Cheng Yu Machinery Technology Co., Ltd. offers an unparalleled range in grinding technology with CYMT CNC Profile Grinding Machines and Punching Bar Grinding Machines. These machines are engineered to perfection for delivering top-notch metal surface finishing.

Thanks to the CYMT-CNC system, operating these machines has never been simpler. The user-friendly design significantly streamlines operating procedures.

This innovative system not only enhances control but also elevates the performance of CNC grinding machines to new heights.

Our machines are designed for ease, ensuring that whether you are a novice or an expert, you'll find them easy to learn and master.

| parameter | 520CNC | 730CNC | ||

| Travel | Table size (x*y) | mm | 200×450 | 300×650 |

| X axis travel | mm | 450 | 650 | |

| Y axis travel | mm | 200 | 300 | |

| Max center of wheel to table | mm | 400 | 400 | |

| Maximum load | kg | 100 | 200 | |

| Table | Table T cell specification | mm×N | 12×3 | 12×5 |

| Table speed | m/min | 0-25 | 0-25 | |

Y axis | Minimum feed | mm | 0.0001 | 0.0001 |

| Single feed | 0.0001~10 | 0.0001~10 | ||

| Fast moving speed | mm/min | 0~5000 | 0~5000 | |

Z axis | Minimum feed | mm | 0.0001 | 0.0001 |

| Fast moving speed | mm/min | 0~5000 | 0~5000 | |

grinding | grinding wheel size max | mm | Φ180×Φ31.75×20 | Φ180×Φ31.75×20 |

| grinding wheel speed | R.P.M | 0~4500 | 0~4500 | |

motor | spindle motor | W | 3700 | 5500 |

| the Z axis motor | W | 1700 | 1700 | |

| the Y axis motor | W | 750 | 1100 | |

| the X axis motor | W | 750 | 1100 | |

| cooling motor | W | 90 | 90 | |

| Roller dresser motor (optional) | W | 750 | 750 | |

| Fourth axis motor | W | 750 | 1100 | |

Size | height of machine | m | 1.8*1.8*1.9 | 2.2*2.0*2.0 |

| floor space | m | 2.1*2.3*2.1 | 2.5*2.5*2.2 | |

| weight(about) | kg | ≈1600 | ≈2800 |

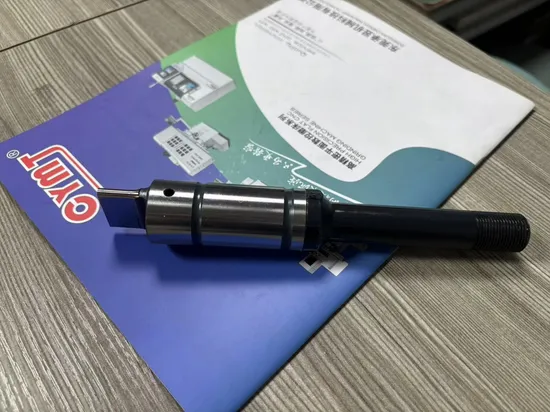

| general picture | Maximum clamping diameter | mm | 25 | 45 |

| Maximum perforation diameter of indexing head | mm | 25 | 45 | |

| Positioning and Repeat Positioning Accuracy≤ | mm | 0.003 | 0.003 | |

| Transverse machining length (standard installation) | mm | 150 | 300 | |

| Vertical processing length (standard installation) | mm | 60 | 160 |

Controller Functions and Features

CYMT-CNC Control System

The sophisticated Cheng Yu CYMT-CNC controller boasts a multitude of advanced features and functionalities. With superior computational power and an enriched Human-Machine Interface (HMI), users are liberated from the need to write complex programs or use UG programming. Seamlessly execute large-scale and intricate machining processes. Notably, the process can be paused to adjust processing parameters, resuming from the exact point of suspension. This ensures efficient parameter optimization for enhanced productivity.

Features

1. No matter the complexity of the shape, a simple program suffices. Just edit a tooth shape and utilize the graphic display function to bring your design to life.

2. The grinding wheel array function allows for the repair of multiple repetitive shapes on a single wheel, promoting cyclic use and efficiency.

3. Enjoy the convenience of the automatic tool setting function. Specify the punch bar diameter and YZ reference with ease, providing data transparency at a glance.

4. With the handwheel simulation trial processing function, beginners can avoid crashes due to setting errors, ensuring safety and precision.

5. The extra grinding and processing complementary function makes processing tolerance straightforward and manageable, ensuring high-quality outcomes.

6. The scheduled grinding function allows for self-programmed multi-processing, maximizing flexibility and efficiency in operations.

7. Choose from a variety of preset processing types for effortless programming. For instance, enter the length and width for waist circle processing, and let the machine handle the rest, including eccentricity adjustments.

8. With the grinding wheel memory function, you can effortlessly reuse previously used wheels without the need for resetting, enhancing operational convenience.

9. Modify processing technology freely, unlocking boundless potential for efficiency improvements and innovation.

Company Profile

Cheng Yu Machinery Technology Co., Ltd. was born in the dynamic heart of Dongguan City, Guangdong Province, seamlessly blending 30 years of Taiwanese expertise in grinding machine manufacturing with cutting-edge technological advancements. Our team of seasoned professionals embodies this rich heritage of innovative design and engineering excellence.

In the fast-evolving realm of CNC machine tools, the future is not just on the horizon; it's here and now with high-speed precision, multi-functional capabilities, intelligent systems, open architectures, parallel drive mechanisms, and networking. Embracing green environmental standards is no longer a luxury but a necessity that defines the modern CNC machinery trajectory. At Dongguan Chengyu Machinery Technology Co., Ltd., we're not just producers; we are curators of precision and innovation in machine tools and accessories. Our core philosophy of 'technology, innovation, and reliability' is embodied in our meticulous quality policy. We focus on understanding our customers' processes, production types, and quality needs. This lays the foundation for our product design and production technology, driving us to enhance the applicability of our offerings and expanding the numerical control industry's frontiers. With high automation, precision, and quality at the forefront, our comprehensive quality management system, state-of-the-art equipment, and exceptional technology ensure excellence. Driven by market demands, Chengyu Machinery has carved a niche in designing and manufacturing high-precision solutions, ranging from CNC surface grinding machines and forming machines to sophisticated four-axis punch grinders, vertical slider grinders, and gantry rail grinders. Our expertise extends to industrial robots, automated production lines, and integrated applications. Here’s a glimpse into our CNC grinding machine series: I. HS Series (Models: 618 / 250 / 3060 / 4080 / 40100) - Available in servo and hydraulic types Processing capacity: Masterful at surface grinding and grooving operations Innovative patented hydraulic control system (hydraulic type) Functions: Equipped with versatile grinding programs for flat surfaces and precise groove cutting Feed mode: Customize your grinding experience with selectable front, back, left, or right options, with memory retention for each program Safety feature: Automatic shutdown in case of grinding wheel overload II. Advanced Series (servo and hydraulic types) Processing capacity: Excels in surface grinding, grooving, and sophisticated scheduling combinations Innovative patented hydraulic control system (hydraulic type) Functions: A suite of grinding programs including surface, grooves, sole, side, unequal distance, and depth displacement grinding Grinding wheel dressing: Automated routine for base plane dressing based on coarse and fine grinding schedules, includes automatic dressing and compensation Feed mode: Selectable front, back, left, or right modes with program-specific memory retention Grooving options: Capable of equidistant and non-equidistant unequal grooves III. Four-Axis CNC Grinding Machines - Available in horizontal and vertical configurations Processing capabilities: Accommodates arbitrary equal division and specialized skipping tooth processes Tailored waist circle processing with AB size input Triangle fillet precision: Input the inscribed circle size B and fillet radius R Quadrilateral fillet processing: Enter side lengths A and B along with fillet size R Eccentric circle operations: Input eccentricity and the starting/ending diameters Circle processing: Enter starting and ending diameters for seamless operations Arc functions: Define arc size and rotation angle for precise arc formations Additional capabilities: Includes step difference and rotation profile functionalities Processing schedules can be meticulously saved as files for effortless future retrieval and operation.

FAQ

1.What is your advance?

A:(1)We have ourselves factory. We accept the order if you want to customize products or design the product.

(2)Professional website platform and one-to-one online service.

(3)Various products in low MOQ and competitive prices.

(4)We have a strong R&D team and now we have 52 patents products.

(5)80% exporting products have been sold to Europe,America and Japan, high quality.

2. What's the minimum order quantity?

A: One set is acceptable

3. How about the payment Term?

A: We accept T/T,Western Union,LC

4. What's your port?

A: Shenzhen/Guangzhou.

5. Can we use our own shipping agent?

A: Yes,you can. we had cooperated with many forwarders.If you need,We can recommend some forwarders to you and you can compare the

price and the service.

6. Can we use our own LOGO or design for sticker?

A: Yes,you can contact with the salesman. And sent us more details about the LOGO or sticker.

7. How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to

quantity.

8. Do you provide samples? Is it free or extra ?

A: Yes, we could offer the sample for cheaper price but do not pay the cost of freight.

>> China Linen Cotton Fabric Manufacturer Customized Home Textile Digital Print Linen Cotton Viscose Fabric for Garment Household

>> Deep Throat Depth CNC Hydraulic Press Brake

>> Low Price Chinese Sinotruk New HOWO 6cbm 4X2 Light Truck Garbage Truck for Sale

>> Tilt in Spece Mobility Kid Chair for Old People Electric Rise Recliner Massage

>> Discount Cowtotal Factory Universal Auto Car Electric Fuel Pump for Toyota Corolla Noah Innova Hyundai Nissan Mitsubishi Pajero Chevrolet Mazda3 Suzuki

>> JIMBO smart 20 guns metal digital storage fire resistant gun safe cabinet

>> 50 Meters Dental Floss Nylon Floss Waxed with Mint Flavor Customized

>> St-747e Direct Drive Motor Overlock Industrial Sewing Machine Textile Machine

>> High Quality Biomass Comprehensive Crusher, China Alva Woodworking Machinery, Wood Chipper

>> Office Small Automatic 2 Roller Adjustable 220mm Width Photo A4 Hot Cold Laminator Laminating Machine

>> Timing Chain Kit Ford with OE 5W7Z6268AA F6AZ6L266CA 1L2Z62253BA TK4690

>> 2030c Woodwork Machinery Furniture Molding Wood German CNC Machines Other Woodworking Machinery

>> YOU KISS shelby style body kit for ford mustang

>> Metal Roll Forming Line with Servo Flying Punching& Servo Flying Cutting

>> Toptooling Custom 2K and 3K Overmolding Plastic Injection Molds

>> G1/2" Brass Nickel Plated Hexagonal Nut

>> Highspeed Plastic Injection Molding Machine Pet350 Produce Food Containers

>> Semi Auto / Semi Automatic Pet Blow Molding Machine for Plastic Bottle

>> Hot Seller Wooden Rubber Paint Kendama Toy Wholesale

>> Rocky Buffalo Occupational Clogs White Ob ESD Microfiber Upper Clogs

>> Surface Multi-Purpose Grinding Machine for Grinding Internal and External Cylindrical and Conical Workpieces

>> Precision and Efficient Intelligent Moon Cake Egg Yolk Crisp Snow Mei Niang Shortcake Molding Equipment

>> High Speed Metal Circular Saw Machine SD-50r

>> Multifunctional Fishing Tackle Bags Single Shoulder Crossbody Bag Waist Pack Fish Lures Gear Utility Storage Fishing Bag

>> Small Lifting Block of 5ton Chain Block Manual Chain Hoist

>> Bestchickencage Ventilation Control System China Poultry Barn Ventilation System Factory Sample Available Saving Energy Ventilation Systems for Broilers

>> Hydraulic Type Automatic Small Plastic Water Bottle Pet Preform Injection Making Machine

>> High Efficiency Meat and Bone Crusher for Feed Processing Plant

>> Good Drainage Root Control Series Plastic Nusery Pot for Green House

>> IGBT Single Tube Inverter Air Plasma Cutter, Cut 40 Air Plasma Cutting Machine