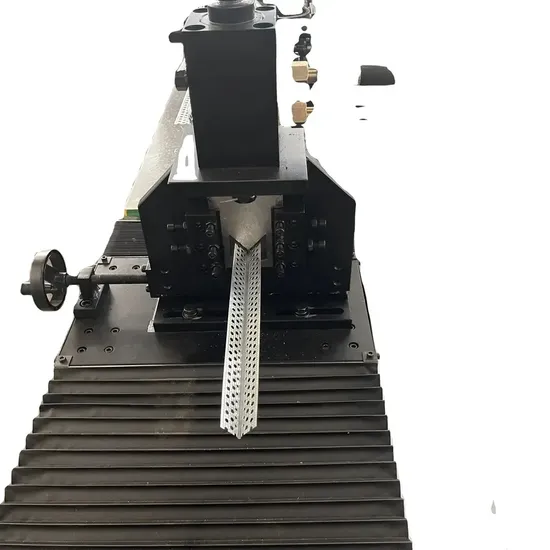

Fast Speed Angle Bead Roll Forming Machine Drywall Corner Bead Making Machine 01

Basic Info.

Model NO.

ZH233

Tile Type

Colored Steel

Certification

CE

Condition

New

Customized

Customized

Usage

Roof, Wall, Floor

Delivery Time

40 Days

Key Selling Point1

Easy to Operate

Key Selling Point2

High Quality

Key Selling Point3

Durable Parts

Transport Package

Plastic File

Specification

6800mm*1.35mm*1.3mm

Trademark

Zhongheng

Origin

Hebei, China

HS Code

8455221000

Production Capacity

20 Sets Per Month

Packaging & Delivery

Package Size

100.00cm * 30.00cm * 50.00cm

Package Gross Weight

50.000kg

Product Description

Key attributes Industry-specific attributes TypeTile Forming Machine

Tile Type

Steel

Use

ROOF

Voltage

380V or as required

Rolling thinckness

0.3-0.8mm

Feeding width

1220mm

Other attributes Production Capacity

10-20m/min

Place of Origin

Hebei, China

Weight

4000 kg

Warranty

1 Year

Key Selling Points

Easy to Operate

Core Components

Pressure vessel, motor, Bearing, Gear, Pump, Gearbox, Engine, PLC, Other

Brand Name

ZHONGHENG

Dimension(L*W*H)

7*1.6*1.5 m

Machinery Test Report

Provided

Video outgoing-inspection

Provided

Name

Angle bead roll forming machine

Control system

PLC(imported Brand)

Color

Client's Request

Usage

roof panel

After-sales Service Provided

Video Technical Support

Cutting blade material

Cr 12 High Grade Steel

Packaging and delivery Packaging Details

1.Good Price Corrugated Iron Sheet Roofing Tile Making Roll Forming Machine need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Port

Tianjin

Selling Units:

Single item

Single package size:

100X30X50 cm

Single gross weight:

2000.000 kg

Supply Ability Supply Ability

20 Set/Sets per Month

Product descriptions from the supplier Product Display

1.CE,ISO certification

2.Custom Design Acceptable

3.Higher Precision And Faster Speed

As a professional manufacturer,we can make Portable KR-18 standing seam roofing machine snap lock metal roof panel machine by customer`s demand, with a profile drawing and thickness, we can design the machine quickly.Until now,we can do many kinds of roof panel machine,such as trapezoidal sheet making machine, corrugated sheet making machine, glazed tile making machine, Double Layer Roll Forming Machine and so on.

Components and Function

| Suitable material | PPGI GI AL |

| Coil Width | 50mm |

| Thickness | 0.5mm-0.8mm |

| Power | 380V 50Hz 3Phase as custom |

| Main motor | 5.5KW |

| Hydraulic motor | 4KW |

| Speed | 10-40m/min |

| Forming stations | 10rows |

| Roller material | Cr12 steel with vacuum heat treatment HRC57°-60° |

| Shaft material | 45# steel quenched and tempered |

| Screem HMI | Delta , Touch Screen |

| PLC | Delta , Siemens |

| Processing precision | Within 1mm |

| Weight | 5T |

>> relojes skmei 1669 gold watch relogio digital steel wristwatches

>> Syrup Vial Ampoule Oral Liquid Filling Machine Plastic Ampoule Liquid Dispensing Equipment

>> HS1421 Heavy Duty Truck Part Vg1560080022 HOWO 336 Electric Fuel Injection Pump

>> China Three-Dimensional Blow Molding Machine (Robot)

>> High Quality Chunmee Tea Te Verde 41022AAA for Mali Senegal Mauritania

>> 4 in 1 Fiber Laser Welding Cutting Cleaning Machine

>> Land Leveling System Farm Machines Tractor Trailed 3 Point Mounted Laser Grader with Laser Level

>> High Speed Common Nail Manufacturing Machinery Automatic Steel Nail Production Line Make Machine Set Wire Nail Making Machine

>> China new product bay design PVC garden windows

>> 150W LED Corn Bulb Replace 400W Metal Halide Ce RoHS

>> Popping Boba/Explosive Pearls/Crispy Waves/Crystal Balls/Milk Tea Pearl Production Equipment

>> REVO Engine A14NET A14XEL timing chain kit for OPEL 5636360 55562235 5636453 TK1017-6

>> High Quality Impact Resistant Material High Purity Magnesium Ingots

>> Zimbabwe Ibr Galvanized Roof Tile Roll Forming Machine

>> Hamai Style CNC Duplex Milling Machine Th-550nc CNC Twin Head Milling Machine

>> New style Universal exhaust tips muffler for amg w204 11-14 AMG

>> China OEM Reliable Manufacturer 9000 BTU Electric Air Conditioner

>> Most Popular Fluorescent Dark Green Coolant Dye

>> Custom Fashion Ladies Short Sleeve Red Floral Crochet Lace MIDI Sleek Ladies Party Dress

>> Household Christmas Decoration Bumble Inflatable Abominable Snowman

>> Australia standard modern aluminum double glazed awning window with fixed panel

>> Modern Layout Design Layer Chicken Cage Laying Hens Cage

>> Custom Design Factory Working Table Workstation Workbench

>> Chicken Layer Cages Price Battery Cage Design Battery Cages for Chicken Laying

>> Yh-Six Colors Six Stations Screen Printer Machine (yinghe brand)

>> 7 Inch SD USB Digital Photo Frame in Plastic

>> Punched Hole aluminum anti skid Serrated walkway Grip Strut perforated plank grating

>> Adv 508-RW1300 Metal Working Sheet Surface Deburring Polishing Machine

>> Stn 5.1 Inch 240*128 Resolution Stn LCD Module

>> Pallet Roll-in Low Profile Lift Table