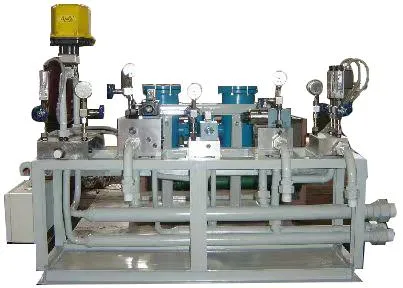

Hollysys Low-Pressure High-Pressure Anti-Wear Fire-Resistant Oil Control Eh Hydraulic Control System

| US$799.00-23,900.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

EH Hydraulic Control System

Certification

IEC61131-2; IEC61000-4

Speed Adjustment Range

Turning Gear Speed at 120% of Rated Speed

Speed Measurement Accuracy

≤ ±1 R/Min

Load Control Range

0 to 120%, Accuracy 0.5%

Speed Variation Ratio

Continuously Adjustable Within a Range of 3 to 6%

Control System Insensitivity

< 0.06%

Maximum Overspeed at Full Load

< 7% of Rated Speed and Able to Maintain Idling

Steam Extraction Pressure Unevenness

0 to 20%

System Control Cycle

< 50 Ms

Minimum IEC Operating Cycle

10 Ms

Transport Package

Standard Packing

Trademark

HollySys

Origin

China

HS Code

9032899099

Production Capacity

5000 Sets/Year

Product Description

The hydraulic control system exists in various forms, including the low-pressure turbine oil control system, the high pressure anti-wear oil control system, and the high-pressure fire-resistant oil control system.Low Pressure Turbine Oil Control System (EH-HLP)Introduction

The low pressure turbine oil control system retains the power oil source from the original hydraulic control system, which is the main oil pump supply method. The control valve actuatoris converted to an electro-hydraulic servo actuator. The control valve is managed through the original valve mechanism (cam or lift plate). The valve position command signal generated by the DEH system is processed through the servo amplifier board and the electro-hydraulic converter valve, forming the control oil pressure to the throttle valve, thereby actuating the servo motor. The actuator stroke is measured by a displacement sensor and fed back to the input of the servo amplifier board, ensuring it matches the valve position command. This allows the actuator stroke to be fully controlled by the DEH system.

High Pressure Anti-Wear Oil Control System (EH-ZRS)Introduction

The high-pressure anti-wear oil control system includes an integrated independent oil source, providing a qualified high-pressure working oil source for the normal operation of the entire hydraulic control system. The working fluid uses environmentally friendly anti wear hydraulic oil with turbine oil characteristics, offering the same control precision and fire-resistant properties. This system features high positioning accuracy, large driving force, stepless speed regulation, and rapid shutdown protection, making it highly cost effective and suitable for small to medium-sized units. Its main components include an independent oil source unit (oil station, accumulator, anti-wear hydraulic oil, etc.), a servo actuator (servo motor, servo valve, OPC solenoid directional valve, etc.), a trip control system, and an oil pipeline system (oil pipelines and various valves).

System Features

· High precision: FIndependent oil source pressure of 14.0 MPa, and high output stiffness for an actuator

· Reliability: Anti-wear hydraulic oil, no environmental pollution, redundant configuration of the oil supply pump in the oil supply system, and two sets of oil pumps mutually reserved

· Availability: 100% continuous adjustable work, and closed-loop servo control system

· Rapidity: Dynamic response time < 0.3s, and fast closing time < 0.2s

· Convenience: Actuator that is compact in size and easy to install, disassembly of the actuator not required for annual maintenance, and replacing only the seals of the hydraulic components on the pump station and actuatorT800N DEHIntroduction

The high-pressure fire-resistant oil control system includes an integrated independent oil source, providing a qualified high-pressure working oil source for the normal operation of the entire hydraulic control system. The working fluid uses phosphate ester fire resistant hydraulic oil, offering high positioning accuracy, large driving force, stepless speed regulation, and rapid shutdown protection, making it suitable for large units. Its main equipment includes an independent oil source unit (oil station, regeneration unit, accumulator, fire-resistant oil, etc.), a servo actuator (actuator, servo valve, OPC solenoid directional valve, etc.), a trip control system, and an oil pipeline system (oil pipelines and various valves).

System Features

· High precision: Independent oil source pressure of 14.0 MPa, and high output stiffness for an actuator

· Reliability: Redundant configuration of the oil supply pump in the oil supply system, and two sets of oil pumps mutually reserved

· Rapidity: Dynamic response time < 0.3s, and fast closing time < 0.2s

· Oil requirement: Phosphoric acid grease resistant fuel

· Maintenance requirement: Regular replacement required for short life of the anti-fuel oil, regular testing required for oil quality, filtration, purification, replacement, and maintenance of equipment

Turbine Control System Overview

Introduction

As the three necessary systems for turbine control, DEH is mainly responsible for controlling the startup, speed increase, operating under load and load regulation of the turbine to ensure stable operation of a turbine unit. ETS is mainly responsible for automatically and quickly cutting off the steam intake of a turbine when a fault occurs to protect the unit. TSI can continuously, accurately and reliably monitor the important parameters of turbine startup, operation and shutdown through sensors. When the monitored parameters exceed the limit, it can accurately and timely reports alarms or shutdown signals.

Features and Advantages

· Intelligent Velocity Measurement: The DEH special speed measurement module (3 out of 2) adopts the latest all-digital circuit, which can generate primary frequency regulation quantity, and cooperate with the servo module to complete the fast primary frequency control function.

· Efficient Configuration: With built-in fast DP (redundant) bus and CAN (redundant) bus, the primary frequency control function adopts independent high-speed CAN bus fast communication loop technology, featuring quick response.

· Intelligent Servo: The DEH special servo module adopts the latest all-digital circuit, and cooperates with the DEH special speed measurement module to complete the fast primary frequency control function through the CAN bus.

· Redundancy and Reliability: Servo module adopts redundancy configuration. Any servo channel can realize online redundant hot standby, and can automatically switch to the standby module when it is judged that the working module is faulty, and the switching time of the servo module is ≤ 10 ms. Servo valve adopts redundancy configuration. Two servo valves receive command signals at the same time to drive the oil motive to act. When one of the servo valves is determined to be faulty, a closure command is issued to the lockout valve of that servo valve. Subsequently, the remaining servo valve takes over all operations while an isolation electromagnetic valve is actuated to cut off the oil flow. Additionally, a shut-off valve on the oil line is used to isolate the fault point for maintenance, ensuring the continuous operation of the unit.

· Quick Master Control: The minimum IEC operating period of the controller is 10 ms, which can meet the rapidity requirements of ultra-supercritical units.

· Fast Frequency Regulation: With qualified primary frequency regulation capability, DEH can make the regulation period lower than 30 ms (non-control period).

· High-Performance Hydraulic Control: The hydraulic control system utilizes an independent high pressure 14 MPa control oil source, and the control of the oil actuated motor is integrated into the servo control system. This hydraulic control system is capable of achieving an oil actuated motor response time of less than 0.3s.

Applicable Model

Technical Parameters

· Speed adjustment range: Turning gear speed at 120% of rated speed

· Speed measurement accuracy: ≤ ±1 r/min Load control range 0 to 120%, accuracy 0.5%

· Speed variation ratio: Continuously adjustable within a range of 3 to 6%

· Control system insensitivity: < 0.06%

· Maximum overspeed at full load: < 7% of rated speed and able to maintain idling

· Steam extraction pressure control accuracy: ±0.01 MPa (suitable for C/CC units)

· Steam extraction pressure unevenness: 0 to 20%

· System control cycle: < 50 ms

· Minimum IEC operating cycle: 10 ms

· Anti-interference measure: Resistance to interference from various electromagnetic waves and communication devices on site, complying with IEC61131-2 and IEC61000-4 standards.

Company Profile

>> Taijia High quality Concrete strength test Schmidt Testing Rebound Hammer

>> Catalyst Dispenser for Catalyst or Styren - 15ml Graduated - Clearcolor

>> Alternator and Starter Training Platform

>> Wireless Remote Control Electric Longboard Skateboard

>> Upgraded Front Dump Underground Wheeled Scaling Jumbo Mining Crushing Trolley

>> True Wireless Stereo Wireless Earbuds Bt Headphone Earphone Electronics Tws I12

>> 3.5ton 3.5t 3500kgs Diesel Forklift Trucks Toyota Model CE with Japanese Isuzu C240 Engine Fork Lift Hyster/Yale/Linde/Crown/Toyota/Hangcha/Komats

>> CNC Wheel Lathe Machine Manufacture Horizontal Lathe CNC Machine

>> Adf Stylish Wine Tote Bag for Easy Transport and Storage 2 Bottles Wine Bag

>> European Style Carb 2 Vinyl Engineered Parquet Plank Wooden Laminated Laminate Wood Flooring

>> High Speed A4/A3 Paper Roll to Sheets Cutting Machine (One Roll Feeding)

>> Boom Barrier Gate System High Speed Drop Arm Barrier Gate for Car Parking Management

>> UL Approved Pendent Fire Sprinkler

>> Cement hydraulic roof color tile machine

>> High quality & best price FOR Chevrolet Onix 2020-2021 Front fog lamp Cover Right 26215448

>> Timing Chain Guide for Toyota Corolla 1NRFE 1.3L OEM 1356647010 1356647030 TR1050

>> Portable Complete Badminton Net Stand Set Storage Box Base with 2 Battledores 2 Shuttlecocks

>> The Cheapest 150cc Air-Cooled Engine Three-Wheeled Motorcycle Agricultural Cargo Three-Wheeled Motorcycle

>> Industrial-Grade Tire Shredder for Optimal Waste Management Solutions

>> Gasoline Mini Tiller/Cultivator/Weeder 4-Stroke Air-Cooled Efficient Power

>> Direct Dyes Yellow 106 for Paper Dyeing

>> PP Body kits for Land Rover Range Rover Evoque Body kits 2016-2018 EVOQUE SVR Style body kits for 2018 Range Rover Evoque

>> Ball Pen

>> Good quality pine lvl beam for construction 65*95 mm

>> Windshield Wiper Motor MB623285 for Mitsubishi Pajero Sport L200 Trion Strada 96-04

>> Manual Radial Z3032X10 Drilling Press Machine Manufacturers Mechanical Rocker Arm Drilling Machine

>> Shred More, Faster! Best Industrial Paper Shredder with Feeding Conveyor

>> High-Speed Pcie X4 Gigabit Ethernet Card with 4 RJ45 Ports

>> SINOBI Gentleman Business Wristwatches Exquisite Calender Window Display Quartz Men Classic Watch Jam Tangan Pria S9829G-D

>> aluminum arched glass casement door for villa