Hanbs Swiss CNC Lathe with Fewer Test Runs

| US$40,100.00-40,500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HS-320

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Contour Control

Control Method

Program Control

Numerical Control

CNC/MNC

Processing Precision

0.02~0.03(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE

Condition

New

Optional System

Fanuc

Spindle

Single Spindle

Transport Package

Wood

Specification

2250X1200X1850mm

Trademark

HANBS

Origin

China

Production Capacity

40sets/Month

Packaging & Delivery

Package Size

2500.00cm * 1400.00cm * 2130.00cm

Package Gross Weight

3000.000kg

Product Description

Hs-320 Swiss CNC Lathe with Fewer Test RunsProduct Description

Enhanced Precision and Accuracy:

With CNC machining, computer programs precisely control every movement of the machine, ensuring unparalleled accuracy and consistency.

Increased Efficiency and Productivity: CNC machines are capable of running continuously for extended periods without any breaks or interruptions. This allows manufacturers to achieve higher production rates and meet tight deadlines efficiently.

Versatility for Complex Designs:

One significant advantage of CNC machining is its ability to handle complex designs with ease, CNC machines can precisely execute complex designs by following instructions from CAD (Computer-Aided Design) programs.

Cost-effectiveness and Time-saving:

the precise and consistent nature of CNC machining eliminates the need for extensive quality control inspections, saving both time and money in the production process.

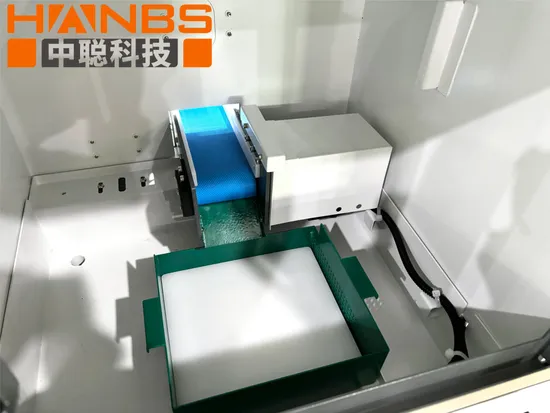

Product Photoes

The spindle adopts high precision internal mounted electric spindle.

Double-channel design, significantly improve the production efficiency.

Optional functions

Product Information

| Project | ||

| Processing references | Maximum machining diameter | Φ20mm |

| Maximum machining length | 190mm | |

| Maximum axial bore diameter | Φ10mm | |

| Maximum axial work wire size | M8 | |

| Maximum spindle speed | 10000rpm | |

| Radial maximum bore diameter | Φ7mm | |

| Radial maximum bore tapping size | M6 | |

| Radial power head maximum rotation speed | ER11:10000/ER16:8000 | |

| Rated speed of radial power head | ER11:8000/ER16:6000 | |

| Maximum workpiece removal length | 100mm | |

Tool dimension | Number of knives installed | 6 |

| Tool (turning tool) | 12X12 | |

| sleeve | Φ25.0 X 4 | |

| Clip head guide sleeve | Spindle spring collet | TSUGAMI B0205CCR |

| Power head collet | ER11,ER16 | |

| Guide bushing | TSUGAMI BS-20#-B | |

| Feeding speed | Z1/Y-axis feed velocity | 30m/min |

| X1 | 20m/min | |

| Electric motor | Spindle drive power | 2.5/3.7KW |

| Power head drive power | 1KW | |

| For cutting fluid | 0.4KW | |

| Cooling of spindle | 0.075KW | |

| Lubricating oil | 0.01KW | |

| Others | Spindle center height | 1060mm |

| Barometric flow | 0.7mpa 0.5m³/min | |

| Main circuit breaker capacity | 40A | |

| Input power | 9.3KW | |

| Weight | 2.6T | |

| Overall dimensions | 2250X1200X1850mm |

Processing case

Factory

Packing&Shipping

Certifications

Q&A

1: How to select machine tools?

A: For selection, please send us the drawing of the turned part, our engineers will evaluate the drawing and provide the CNC lathe configuration that suits your needs.

2: What are your main products?

A: SmartLathe has concentrated all its resources to successfully develop the HS series of Swiss CNC lathes, including HS-820, HS-926, HS-320, HS-512 and CNC machines.

3: Where is our factory located? How to visit?

A: Our factory is located in Dalang Town, Dongguan City, Guangdong Province, China. We warmly welcome you to visit our factory.

4: What are the trade and payment terms?

A: FOB, CFR, CIF and EXW are acceptable. t/t, l/c, d/p.

5: What is the maximum order quantity?

A: 1 set. If you order more, we will offer you more favourable price.

6: What is the delivery time?

A: Full range of standard models are in stock. As for customisation, it depends on the situation.

7. Do you have any certificates?

A: Yes, our machines are CE compliant and our factory is ISO 9001 certified.

8. How long is the warranty period?

A: The warranty period is normally 12 months after the bill of lading date. 9.

9. Machine installation.

A: If the buyer requests, we can assign technicians to install on site.

10. Technical support

A: We provide technical response within 12 hours and troubleshooting solution within 48 hours.

>> Automatic CNC Reinforce Concrete Spun Pile Cage Welding Machine

>> Construction Material Composite Pipe & Tube PPR Thermal Insulation Pipe

>> 13.4L ISO Tped Seamless Steel Portable Household Health Care Medical Oxygen Gas Cylinder

>> Unleash Granite and Marble Block Quarrying Potential with Stonewin′s 12mm Diamond Wire Saw: Precision in Action

>> Door to Door Sea Freight From China to Europe

>> Colorful Plastic Sheets Custom-Made Plastic Parts Cast Nylon Sheet Plastic Boards

>> Disposable Square Palm Leaf Plates Compostable Heavy Duty Dinner Plates

>> High Output Plastic Pet Bottles Recycling Machine Pet Plastic Flakes Floating Washer Machine

>> Hoade Second Hand 2021 Concrete Pump Truck 67m with Cheap Price

>> 50W Deep Laser Engraving Fiber Laser Marking Machine for Metal

>> Ukiss Genuine Car Parts Front Hood Bonnet For BMW 3 4 Series F30 F35 F32 F33 F36 Facelift CS Aluminum Front Hood Engine Covers

>> Factory Metal CNC Engraving Milling Chamfaring Machine Tat760

>> PVC Insulated Oxygen Free Copper Conductor Audio Connector Speaker Cable

>> ISO2531 En545 En598 Ductile Iron Pipe Class K7 K9 K12 C40 C30 C25

>> 600*600 Interior Decoration Aluminum Expanded Metal Ceiling Titles

>> Personalized Beverage Design ODM Craft Beer Beverage Export Beer

>> Excellent Polishing Industrial OEM Screw Die Custom-Designed for CNC Lathes

>> High Quality 5kw High Frequency 2000ml Urine Bag Welding Making Machine with Sliding Table

>> 5tonne European Standard Electric Wire Rope Hoist for Single Rail Electric Trolley

>> Mini Electric Chain/ Wire Rope Hoist for Lifting Goods

>> Dialead Power Tool Core Drill Bit Diamond Segment for Reinforce Concrete

>> High Power 15kHz Ultrasonic Lace Machine for Welding Plastics and Non-Woven Materials

>> Hot dip galvanized steel grating: power plant sewage treatment plant platform step steel grating plug-in composite heavy-duty grating

>> French Secret Lashtoniic Brow & Lash Enhancer Serum Promotes Longer Thicker Lashes

>> TM-8812 Ultrasonic Thickness Gauge From China Ultrasonic Plastic Thickness Gauge,Gauge Plate Sizes

>> Fully Automatic Roll to Sheet Release Paper/Self-Adhesive Label/PVC Film Laminating Cutting Machine

>> 1.5mm Thickness Matte Surface Luxury Vegetable Tanned Corrected Grain Genuine Buffalo Leather

>> Efficient 3.5 Ton LPG Forklift Truck Featuring Nissan Power

>> Industrial Film Blowing Machine Blown Film Machine Lift up and Down

>> 2021 Hot Sale 4 Inch 300psi Frp Ro Membrane Housing/4040 Pressure Vessel Housing