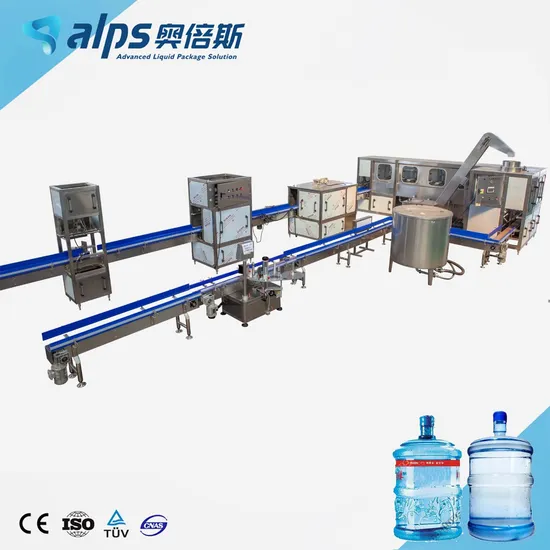

Automatic 5 Gallon 20L Barrel Mineral Pure Drinking Water Production Bottling Plant

| US$32,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

QGF

Type

Volumetric Filling Machine

Automatic Grade

Fully Automatic

Material Type

Liquid

Filling Valve Head

Multi-Head

Feed Cylinder Structure

Multi-Room Feeding

Dosing Device

Plunger

Filling Principle

Atmospheric Pressure

Packaging Container Lifting Structure

Chute Lifting

Structure

Linear

Packaging

Bottle

Packaging Material

Plastic

Keywords

Complete 5 Gallon Barrel Water Production Line

Material

SUS304 / 316L

Filling Product

Pure Water / Mineral Water

Bottle Volume

3 Gallon - 6 Gallon

Filling Precision

1% (Liquid Level)

Capacity

100bph - 2000bph

Bottle Material

PC / Pet

Function

Rinsing Filling Capping

Voltage

Customized

Control

PLC

Certificate

Ce, ISO, SGS

Transport Package

Wooden Case

Specification

30 CBM

Trademark

Alps

Origin

Zhangjiagang

HS Code

8422309010

Production Capacity

10 Sets Per Month

Packaging & Delivery

Package Size

6500.00cm * 2200.00cm * 2600.00cm

Package Gross Weight

3400.000kg

Product Description

Automatic Complete 5 Gallon 20L Barrel Bucket Mineral Drinking Water Bottling Plant Product Description

*We supply complete solution for the recycled bucket water bottling machine,including Water treatment system / Decapping machine / Inside brusher / Externer brusher / Automatic 5 Gallon rinsing filling capping machine / Automatic Cap sleeve label machine / Code sprayer / Film wrapping machine / Automatic 5 gallon palletizer system

| Technical parameter: Gallon Water Filling Machine | ||||||

| Model | QGF-100 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Capacity (for 5 gallon) | 60-100bph | 300bph | 450bph | 600bph | 900bph | 1200bph |

| Suitable bottle shapes | PET circular or square | |||||

| Compressor air | 3 & 5 Gallon | |||||

| Air consumption | 0.3-0.7Mpa | |||||

| Rinsing pressure | 0.37 m3/min | |||||

| Application | recycled bucket water bottling machine | |||||

| Total power (KW) | 1.5kw | 3.8kw | 4.5kw | 5.2kw | 6.2kw | 7.8kw |

| Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height | 1.8m | 2m | 2.2m | 2.3m | 2.5m | 2.6m |

| Weight(kg) | 800kg | 1500kg | 2000kg | 2500kg | 3000kg | 35000kg |

The filling line specially for 3-5 gallons barreled drinking water ,with type QGF-100,QGF-240,QGF-300,QGF450,QGF-600,QGF-600,QGF-900,QGF-1200. It integrateds bottle washing,filling and capping into one unit ,in order to achieve the purpose of washing and sterilizing,The washing machine uses multi-washing liquid spray and thimerosal spray,the thimerosal can be used circularly,The capping machine can be cap barrel automatically ,The line equips with water spraying device in order to ensure those caps sterile and clean, it also can automatically carry out barrel,washing,steriizing,filling,capping,counting and products discharging,with complete function,modern design and high degree of automation ,It is a new kind of barreled water auto producing line ,which integrates mechanism,electricity and pneumatics technologies together

Flow Chart:

1.Decapping Machine ; 2.External Brusher ; 3. Automatic 5 Gallon Rinsing Filling Capping Machine ; 4.Cap elevator ;5.Code sprayer ; 6.Light checker ; 7.Cap film shrinker Machine ; 8 .Plastic bag wrapping machine ; 9.Bucket collect

Cooperated Brand:

FAQ

1.Q:Are you a factory or trading company?

A:We are a factory, professional water treatment system manufacturer and small bottle water filling & packing machinery with about 10 years experience. Factory covers an area of 12000 square. There have been more than 50 countries use our products.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Donglai town,Zhangjiagang city,Jiangsu province,China. about 2 hours away from PVG Airport . All clients are warmly welcome to visit us !

3.How about installation ?

We will send our engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back,accommodation and USD100 / day/person.

4.Q:How long is the warranty of your equipment?

A:2 years warranty after receipt check upon delivery.And we will comprehensively provide you all kinds of technical support services in after-sale service

5.Q:What is the features of our company?

A: We provide turnkey project for customers, including sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training; etc

>> 3 Series E46 M3 E39 M5 2001 2006 Refit New E46 M3 Fog Light for

>> High quality prehung fiberglass exterior double solid wood front doors

>> Leabon CE Certification Maize Stalk Crusher Straw Bale Shredding Machine Price

>> Wholesale Blank Jogger Suit Designer Cotton Oversized Womens Tracksuit Set

>> Rubber Accelerator TBBS (NS) CAS 95-31-8 Vulcanizing Accelerator TBBS From China

>> New Style Corn Maize Thresher Sheller Peeler Corn Peeling Threshing Machine

>> High Speed Light Bench Drill Zhx-13 Table High Precision Drilling Machine Maximum Diameter 13 mm

>> 808nm diode laser hair removal machine and mini laser cutting machine In Guangzhou Renlang

>> Class 3 Professional High Technology Gun Safe Double Vault Door Factory

>> Electric Scrap Lifting Magnet Machine MW5-70L/1

>> Home Decoration Waterproof Click Flooring Nonslip Rigid Core 3.5mm 4mm 5mm 6mm Wood/PVC/Lvt/WPC/Lvt/Vinyl/Spc Flooring Laminate Flooring

>> Kitchen Equipment Sweet Maize Sheller Fresh Corn Threshing Machine

>> Classic Inflatable Water Slide Walking Bouncy Slide for Water Park

>> New Semi-Chrome Front Bumper Upper Grille Front Kidney Grill for BMW X5 E53 51137113733

>> Color Auto Body Paint From Car Paint Factory Hot Sales All Over The World

>> Provide Printing Service Paper Cardboard Bottle Carton Milk Juice Packaging Box

>> UICE 9'' Black Removable Regular Style no Screw Surfboard Fins For Inflatable Paddle Board

>> H12 Non-Return Check Valve Vertical Spring Check Valve Stainless Steel

>> Good Quality Spiral Sand Washing Machine For Washing Iron Ore Silica Sand Minerals Ore

>> Nordic wood shoe cabinet shoe racks cabinet storage organizer

>> Durable CNC Machined Aluminum Extrusion Bracket for Industrial Use

>> Factory Wholesale Solid Material Fishing Rod Spinning Rod, Fishing Pole Fishing Tackle

>> Best Selling Low Carbon Steel High Strength Plate Alloy Structural Steel Sheet Ss400 A36 Q345 Mild Steel Hrs Hot Rolled Steel Plate Black Ms Iron Sheet

>> Square High Quality Huge Capacity Chicken Automatic Double Drum Spiral Oven

>> Premium Quality Top Sellers Custom Design & logo Leather Professional Fitness MMA Boxing Gloves

>> Motorcycle Parts Motorcycle Air Filter Element for Bajaj Pulsar 200ns

>> 2020 new style portable water filter water faucet filter tap water filter

>> Good Choice for Flower Packaging and Table Runner/Table Cloth Jute Linen Like Polyester Fabric Decorative Cloth Home Deco Roll Linen

>> Professional Grade Pool Trampoline for Aquatic Therapy Enhance Recovery

>> Slip-Resistant Outdoor Decking WPC for Safe Family Gatherings