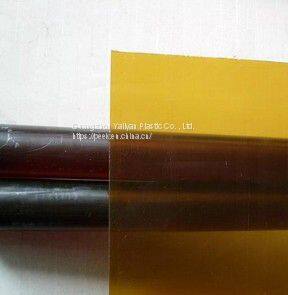

Polyimide Amanium PI Laminated Board

Product Description

Product DescriptionPolyimide is one of the organic polymer materials with the best comprehensive performance, high temperature resistance above 400℃, long-term use temperature range -200 ~ 300℃, no obvious melting point, high insulation performance, dielectric constant 4.0 under 103 Hz, dielectric loss only 0.004 ~ 0.007, F to H grade insulation materials

Polyimide refers to a class of polymers containing an imide ring (-co-N-co -) in the main chain, among which the polymer containing a phthalimide structure is the most important. As a special engineering material, polyimide has been widely used in aviation, aerospace, microelectronics, nano, liquid crystal, separation membrane, laser and other fields. Recently, the research, development and utilization of polyimide are included in the 21st century one of the most promising engineering plastics. Polyimide, because of its outstanding characteristics in performance and synthesis, whether as a structural material or as a functional material, its huge application prospects have been fully recognized, and it is believed that "without polyimide, there would be no microelectronics technology today".

performance

1, polyimide according to thermogravimetric analysis, the start of decomposition temperature is generally around 500℃. Polyimide synthesized by dianhydride of biphenyl tetraformic acid and p-phenylenediamine has a thermal decomposition temperature of 600℃, which is one of the most thermostable varieties in polymers.

2, polyimide can withstand extremely low temperature, such as -269℃ in liquid helium will not be brittle.

3, polyimide has excellent mechanical properties, the tensile strength of unfilled plastic is more than 100Mpa, the film of benzene-type polyimide (Kapton) is more than 170Mpa, and the impact strength of plastic polyimide (TPI) is as high as 261KJ/m2. The biphenyl polyimide (Upilex S) reached 400Mpa. As an engineering plastic, the amount of elastic film is usually 3-4 gpa, and the fiber can reach 200Gpa. According to theoretical calculations, the fiber synthesized by dianhydride and p-phenylenediamine can reach 500Gpa, second only to carbon fiber.

4, some varieties of polyimide insoluble in organic solvents, to dilute acid stability, generally little varieties of resistance to hydrolysis, had the performance of this seemingly faults polyimide is different from the other one big characteristics of high performance polymer, which can take advantage of the alkaline hydrolysis of recycle material dianhydride and diamine, for example, Kapton film, its recovery rate can reach 80% 90%. Changing the structure can also get quite hydrolysis resistant varieties, such as withstand 120℃, 500 hours of water boiling.

5, polyimide thermal expansion coefficient in 2×10-5-3×10-5℃, thermoplastic polyimide 3×10-5℃, biphenyl type up to 10-6℃, individual varieties up to 10-7℃.

6. Polyimide has high radiation resistance, and the intensity retention rate of the film is 90% after 5×109rad fast electron irradiation.

7, polyimide has good dielectric properties, the dielectric constant is about 3.4, the introduction of fluorine, or the air nano size dispersed in polyimide, the dielectric constant can be reduced to about 2.5. The dielectric loss is 10-3, the dielectric strength is 100 to 300KV/mm, the polyimide is 300KV/mm, and the volume resistance is 1017Ω·cm. These performances can be maintained at a high level over a wide range of temperatures and frequencies.

8, polyimide is self-extinguision polymer, low smoke rate.

9, polyimide in a very high vacuum under very little air.

10, polyimide is non-toxic, can be used to make tableware and medical utensils, and can withstand thousands of disinfection. Some polyimides also have good biocompatibility, for example, they are non-hemolytic in blood compatibility test and non-toxic in vitro cytotoxicity test.

Quality indicators

Appearance light yellow powder

Bending strength (20℃) ≥170MPa

Density 1.38 ~ 1.43g/cm3

Impact strength (no notch) ≥28kJ/m2

Tensile strength ≥100 MPa

Veka softening point >270℃

Water absorption (25℃, 24h)

Elongation > 120%

Guangzhou Yayan Plastic Products Co., LTD. Spot supply: PEEK board/rod, PPS board/rod, PVDF board/rod, PTFE board/rod, PSU board/rod, PEI board/rod, PI board/rod, PAI board/rod, PPO board / bar, PBT board/bar, CPVC board/bar, UPE board/bar, PETP board/bar, PC board/bar, POM board/bar, ABS board/bar, PMMA board/bar, PP board/bar, PE board / bar, imported PU board/bar, German PES board/bar, domestic PVC board/bar, Swiss engineering PBI board/bar, German PA nylon series board/bar/piece, MC nylon series board. Insulation materials: Taiwan red, black electric board, cold stamping board, phenolic laminated cloth bar board, heat insulation board, epoxy glass fiber bar board, epoxy board (FR-4) asbestos board, etc. Anti-static products: anti-static POM board/bar, anti-static organic board, anti-static PC board. Anti static PVC board/bar, anti static nylon board/bar synthetic SLATE and so on.

Welcome to call and visit to negotiate!

For more information, call 020-36228290

Mobile phone: 180 2748 2446

QQ: 1006680516

Contact person: Miss Huang

>> 5 Zone 7 Zone Bagged Pocket Spring Foam Mattress Colchones

>> OEM factory 10ml 30ml plastic doypack stand up shampoo spout pouch bag for cats and dogs pet

>> Heavy Duty Petrochemical Process Pump (BB2)

>> ACR Supplier Processing Aid Kf100 PVC Foaming Board Foaming Regulator

>> 2/3 Tier Spice Organizer For Kitchen Counter Multi-functional Metal Storage Rack For Holding Spice, Cutting-board, Knives

>> Sephcare food grade shiny pearl luster dust edible pigment

>> 150Mbps 5dBi 802.11b/G/N Ralink Rt5370 USB WiFi Adapter for Windows 2000/XP/Vista/7/8/10

>> HC-A008 Hot Sale USB ultrasound probe price for pc laptop

>> Bathroom Bamboo Basin Bamboo Sink Bathroom Vanity Accessories Wash Basin

>> 4*8FT Lightweight high quality HDPE Ground Mat Temporary Access Road Mat

>> Roller Type Sand Mixer in Casting Foundry Sand Mixing Machine Price

>> High Efficiency 24V Dc 1Kw 3Kw 230V Ac Inverter & Charger 5Kw Off Grid Solar Inverters Inbuilt Mppt Controller With Limiter

>> Hot Selling in Europe High Precision Lathe DN4025 Drilling Machine

>> Wg Series Lifting Door Pulse Vacuum Autoclave

>> 2G GPRS GSM Module R805C SIMCom

>> Vertical / Horizontal Digital Signage Advertising Box 2K 4K Touch Screen 86 Inch Big Transparent LCD Display

>> Geared Big Head Engine Heavy Duty Face Lathe C6016 Flange Processing Conventional Floor Facing Lathe Machine

>> stepper hydronic nema slide manual stepper exercise stappenteller

>> 5bbl 1000L 10bbl 1500L 2000L Complete Craft Beer Equipment for Microbreweries Nano Breweries Brewpub Restaurants 3 Vessel Brewing Kit Fermentation Tanks

>> Client Specification Modern Free Standing Glasshouse Building Glass Sun Room Heavy Duty Conservatory Sunroom

>> 4M41T MONTERO/PAJERO /SHOGUN/TRITON DOHC 16V 3.2L TK8030 Tming Chain Kit for MITSUBISHI with OE No.ME203100 ME203085

>> High Performance Diesel Engine Motor for Volvo D5d Cce3

>> Bottle Filling Machine Magnetic Pump Mineral Water Essential Oil Fluid Quantitative Filler

>> Promotion Hot Sales 6.5inch Two Wheels Balance Hoverboard

>> 1.5m 5t 75mm Red Polyester Lifting Endless Round Sling En1492-2: 2000

>> Rubber Bladder Water Storage Tanks 200 Liters Rubber Diaphragm Tank

>> HC-G009 Factory price Best Aneroid Sphygmomanometer with Sprague pappaport stethoscope

>> China Laser Engraving Machine for Glass Price Table Top Laser Cutting and Engraving Machine

>> High Precision Aluminum 6061, 6063 CNC Machining Parts for Automation

>> Anon High Efficiency Maize Corn Combine Harvester Versatile Corn Combine Machine