1500kg/H Extra Virgin Olive Oil Production Line by 2 Phase Centrifuge Extraction

| US$90,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LW series

Type

Centrifuge

Separation Mode

Sedimentation Type

Operating Type

Continuous Type

Installation

Horizontal

Centrifuge Type

Horizontal Spiral Centrifuge

Pressure

Low Pressure

Condition

New

Product Name

Olive Oil Extraction Line

Extraction Method

Centrifuge Extraction

Oil Yield

10%

Material

SS304

Transport Package

Export Wooden Case

Specification

9*3*2.5M

Trademark

Shenzhou

Origin

China

Product Description

Product Description1500KG/H Extra Virgin Olive Oil Production Line By 2 Phase Centrifuge Extraction

Olive oil CENTRIFUGE EXTRACTION LINE is designed specially for EXTRA VIRGIN OLIVE OIL extraction from the ready paste by 2-phase or 3-phase separation(which is followed as per local government rules regarding the pollution issues). Cold pressed extraction process could replace the traditional solvent extraction method to produce a virgin olive oil for the edible oil market. Generally,the whole system consists of the following 6 steps 1.- olive fruits reception and leaf removal system 2.- olive fruits washing system 3.- olive fruits crushing and paste malaxing system 4.- olive oil extraction system (2/3 phase optional) 5.- olive oil purification system 6.- olive oil storage and bottling system All components such as decanter centrifuge and vertical separator are made in china!

Configuration List

| S/N. | PROCESS EQUIPMENT | SPECIFICATION | POWER | QTY |

| 1 | WASHING MACHINE | FOOD GRADE SUS304 | / | 1 |

| 2 | AVOCADO DESTONER | FOOD GRADE SUS304 | / | 1 |

| 3 | PULP MALAXER TANK | FOOD GRADE SUS304 | / | 2 |

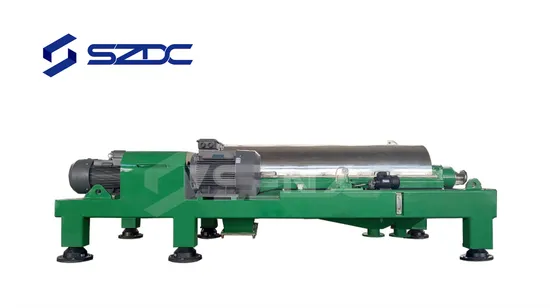

| 4 | DECANTER CENTRIFUGE | FOOD GRADE SUS304 | / | 1 |

| 5 | DISC SEPARATOR | FOOD GRADE SUS304 | / | 1 |

| 6 | CONTROL CABINET | CONTROL THE WHOLE LINE; CARBON STEEL | / | 1 |

Process Drawing

Process Description Storage&Transfer Process The collected fruits shall be put into small baskets first and delivered to factory,The baskets will stack in the ventilate storage warehouse to avoid oxidation&fermentation phenomenon because of the overheat and bruise. Fruit Washing Process The olive fruits are conveyed into the washing machine,then are rinsed and washed to remove the dust under the function of strong water flow.The water is collected for recovery by circulation tank under the vibration sieve. Crushing&Malaxing Process After crushing,the olive fruit pulp will be pumped into the malaxer for further process. The oil drops will be released and merge into large drops which can be separated easily by centrifuge. Pulp Malaxing Process After crushing,the olive pulp will be pumped into the malaxer for further process. The oil drops will be released and merge into large drops which can be separated easily by centrifuge. Centrifuge Extraction Process After malaxing,the decanter centrifuge will be followd to separate the oil from pomace and water.During this process, 2 and 3 phase decanter centrifuge are available to meet production condition. Oil Purification Process After decanter,the oil still contains little moisure and impurities. Here a vertical disc separator is used to saparate the

impurities for final purified virgin olive oil.

Different Models for Choice (The following capacity is based on the Olive fruits input)

| REYES-500 | REYES--1000 | REYES--2000 | REYES--3000 | REYES--5000 | REYES--8000 |

| 500KG/H | 1000KG/H | 2000KG/H | 3000KG/H | 5000KG/H | 8000KG/H |

>> Completely Full Automatic Mineral Pure Water Bottle Filling Machine Plant Production Line From a to Z/Filling Machinery/Liquid Filling Machine/Bottle Filling Ma

>> Guangzhou Depilation Laser Diode Hair Removal Machine good Prices

>> Metal Roofing Drain Ridge Cap Roll Forming Machine

>> Custom Machining Mechanical Parts Metal Aluminum/Brass/Stainless Steel Service

>> 220HP Combine Harvester for Fast and Efficient Corn Harvesting

>> Beater

>> a 400W LED Lightbox Power Supply Specifically Designed for Advertising Signs

>> Outdoor Climbing Multi-function Folding Pliers Stainless Steel Pocket Multi-functionTool Factory Direct Sale

>> Automatic Plastic Bucket Injection Moulding Machine for Making Slipper

>> Concrete Machinery Mortar Plastering Machine with Air Compressor P60K

>> Plastic Weaving Mat Making Machine PP Mat Making Machine, Flat Yarn Mat Weave Loom, Prayer Mat Making Machines Production Line

>> Pet Bottle Scrap Flakes Hot Washing Machine Hot Washer

>> 0.5~7.5mm Manual focus iris for vari-focal mechanical vision lens SLR camera lens follow spotlight

>> Bronco Silent Air-Cooled 5kw 6kw 7kw Silent Type Diesel Generator

>> Giant Star Machinery Good Price Computerized Woolen Making Standard Gauge Knitting Sweater Machine

>> Eco friendly 50k brazil big size pp woven rice packaging bag of rice 50 kg 100kg

>> Horizontal Aluminum Alloy Frame Casement /Sliding Window with Glass Louvre

>> 2023 Low Price Safe and Environmentally Friendly Fiber Laser CNC Cutting Machine for Metal

>> skmei watch review 9127 custom quartz men sport leather band quartz watches

>> Handheld Liquid Explosive Detection Systems SPL-1500(SECUPLUS)

>> Premium 18 Inch High Performance Woofer Speaker Cone Parts

>> D-Shaped Rubber Boat Marine Pier Fender Boat Rubber Fender Strip Rubber Fender Boat Dock Bumpers

>> High-Quality Industrial Grade Granular Urea Fertilizer

>> Tablet Free Fall Tablet Food Candy Garment Conveyor Belt Metal Equipment Ferrous Copper Brass Aluminum Stainless Steel Stannum Metal Machine Detector

>> Rock Picker with Rock Collection Boxes Matched with Tractor

>> High Quality Tr Men Material Poly Viscose Blended Suiting Uniform Fabric

>> Square Body Post Bed Type Sewing Machine Fit-2810

>> Inspection Service Consolidator Shipping to Bolivia/Bosnia/Casablanca/Morocco/Chicago/Conakry/Guinea China Shipping Mexico

>> 100-3000kg/H Wood Pallet Crusher Wood Waste Shredder Machine Industrial Wood Shredder Machine

>> Household Coreless 10kw 15kw Permanent Magnet Generator