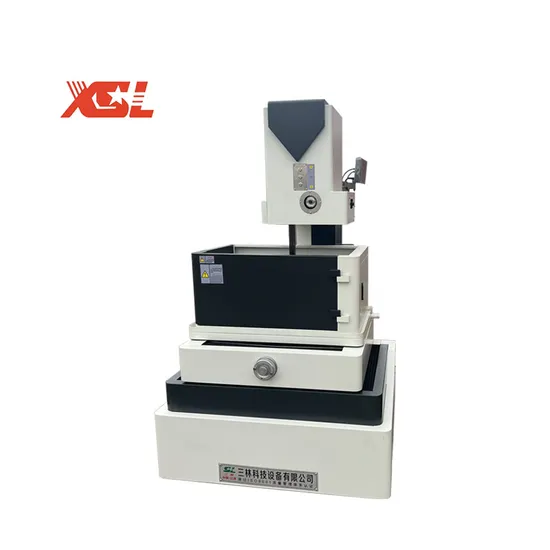

Versatile EDM Wire Cutting Machine with 1-Year Core Warranty

| US$4,000.00-5,000.00 | 1 Piece (MOQ) |

Basic Info.

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools

Movement Method

Contour Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Warranty of Core Components

1 Year

Core Components

Motor, Pump

Working Weight (Kg)

Customized

Worktable Travel (mm)

Customized

Transport Package

Wooden Case

Specification

customized

Trademark

sl

Origin

China

HS Code

8456301090

Production Capacity

100sets/Month

Product Description

| Product model | DK7720 | DK7735 | DK7745F | DK7745 | DK7750 |

| Worktable stroke (mm) | 420*270 | 710*480 | 920*540 | 810*570 | 950*650 |

| Table travel (mm) | 200*250 | 350*450 | 450*700 | 450*550 | 500*630 |

| Machining height (mm) | 200 | 480 | 480 | 480 | 600 |

| Machining taper (mm) | 6°,15°,30°/80 | ||||

| Cutting speed (m/min) | ≥120 | ||||

| Surface roughness/finish(um) | ≤2.5 | ||||

| Electrode wire diameter (mm) | 0.1-0.2 | ||||

| Electrode wire fixed line speed (m/s) | 11.5 | ||||

| Processing accuracy | According to GB7926-2005 standard≤0.02mm | ||||

| Table movement pulse equivalent (mm) | 0.001 | ||||

| Power supply | 50Hz.380V | ||||

| Machine tool power consumption (KVA) | <1.0 | ||||

| Workpiece weight (KG) | 100 | 300 | 450 | 450 | 700 |

| Main machine external dimensions (mm) | 1160*810*1300 | 1240*1170*1400 | 1700*1600*1600 | 1600*1240*1400 | 1720*1680*1700 |

| Product model | DK7750F | DK7763 | DK7763F | DK7780 | DK77100 |

| Worktable stroke (mm) | 1140*650 | 1140*750 | 1350*750 | 1350*985 | 1700*1170 |

| Table travel (mm) | 500*800 | 630*800 | 630*1000 | 800*1000 | 1000*1200 |

| Machining height (mm) | 400/600 | 600 | 600/800 | 600 | 1000 |

| Machining taper (mm) | 6°,15°,30°/80 | ||||

| Cutting speed (m/min) | ≥120 | ||||

| Surface roughness/finish(um) | ≤2.5 | ||||

| Electrode wire diameter (mm) | 0.1-0.2 | ||||

| Electrode wire fixed line speed (m/s) | 11.5 | ||||

| Processing accuracy | According to GB7926-2005 standard≤0.02mm | ||||

| Table movement pulse equivalent (mm) | 0.001 | ||||

| Power supply | 50Hz.380V | ||||

| Machine tool power consumption (KVA) | <1.0 | ||||

| Workpiece weight (KG) | 700 | 1000 | 1000 | 2000 | 2600 |

| Main machine external dimensions (mm) | 2000*1900*1700 | 2100*1940*1780 | 2300*2200*1800 | 2600*2400*1800 | 3000*2800*2500 |

Discover Our Company: Profile

Jiangsu Sanlin Technology Equipment Co., Ltd. Jiangsu Sanlin Technology Equipment Co., Ltd. stands proudly as a high-tech enterprise, expertly blending the art of production, the innovation of research and development, and the strategic acumen of sales within the realm of CNC machinery and equipment. With an esteemed presence in the equipment industry spanning decades, our company specializes in an array of sophisticated machinery including vertical machining centers, high-speed machines, and gantry machining centers, among others. Our portfolio boasts drilling and tapping centers, engraving and milling machines, medium and fast wire cutting machines, and small hole machines, each exemplifying our dedication to quality and craftsmanship. Our equipment finds its home in pivotal manufacturing sectors such as automotive, aerospace, national defense, medical food machinery, rail transit, and metal mold industries. Widely embraced across the nation, our products also make their mark in Southeast Asia, Europe, Africa, and beyond. With Sanlin, expect relentless pursuit of perfection as we aim to deliver exemplary products to our valued users. We warmly invite customers and partners to engage in cooperative ventures with us!

Frequently Asked Questions (FAQ)

A: We are a proud manufacturer and warmly welcome you to explore our factory. A: To choose the right machine model, match the worktable travel and cutting thickness to your workpiece size, and ensure that precision and surface finish meet your expectations. Our TRS series machines are engineered to offer superior precision and an impeccable finish. A: Absolutely, just inform us of your voltage requirements, and we will accommodate them. A: During the warranty period, we offer free replacement for any damaged parts. Beyond that, replacements are available at cost price. For any issues, rest assured, we provide rapid solutions, whether via informative videos or other efficient methods.Q: Are you a manufacturer or distributor? Q: How do I select the ideal machine for my needs? Q: Our local voltage is three-phase 220V (or single-phase 220V, or another specification), while the machine operates at three-phase 380V. Can you adjust the voltage to suit our requirements? Q: What can I expect from your after-sales service?

>> Automatic Wire Straightening and Cutting Machine for Welding

>> Premium Quality 5-Axis CNC Tool Grinding System Equipment with CE Certification

>> Custom No Crush Wheel Polyurethane Light Pressure Sun Wheel for Flexo Printing Spare Parts

>> Kexinda Cross T Bar Forming Machine

>> OEM 316 stainless steel yacht accessories marine hardware boat anchor

>> High Efficiency Knitting Machine Circular Parts for T-Shirt and Sweater Production

>> Trapezoid Tape Cut Machine; Automatic Rope Cutting Machine

>> Diameter 8mm 10mm 12mm 15mm 20mm 30mm 40mm 300mm Natural Mc PA6 Nylon Rod

>> High Speed Sausage Sealing Machine Pillow Bag Hot Dog Packing Machine

>> Full Automatic Small Poultry Animal Livestock Feed Pellet Small Mill Processing Plant

>> Ear Bone Nails Zircon Screw Stud Earrings Women Stud Earrings Piercing Jewelry

>> Cheap Round Hole High Quality Outdoor Waterproof Wood Grain WPC Decking

>> 90% Nylon, 10% Spandex Stretch Waterproof Navy Blue Dobby Textile Fabric for Garment

>> 500 bag/min Automatic Small Candy Sweets Package Pillow Type Packaging Machinery

>> 2.2kw High Shear Mixer High Shear Emulsifying Mixer for Daily Chemical

>> Agricultural Equipment Hot-DIP Galvanized Beef Cattle Headlock

>> Competitively Priced Hot-Selling Customized OEM Aluminum Heatsinks for Personal Computer

>> ABB SCYC51010 58052515G module brand new

>> Pink Cat Toy Camera Block Building Kids Camera Outdoor Kids Camera Children camera for Children’ S Gift

>> China High Quality Fasteners Pem Clinch Nut, Riveting Nuts, Standoffs, Studs

>> LCD Display Single Yarn Strength Tester

>> Module spare parts CFP-AI-100

>> Magnetic Drill Multifunctional Forward and Reverse Magnetic Base Drill

>> Fast Speed UV Printer with Roll to Roll for UV Dtf Sticker

>> Indoor 432X0.5W LED Studio Panel Light LED Stage Light 3200K and 5600K

>> Custom Seg Graphic Fabric Printing with Silicone Edge for Wall Frame Light Box

>> TRICONEX 8111

>> Medical Device Urine Analyzer Components Customized Injection Molds

>> Automatic Rewinding Toilet Paper Roll Making Machine

>> New CE Certified Medical Product Needle Free Insulin Syringe