Circular Saw Blade Grinding Machine Top-Face-Groove Cycle Sharpening in One Set-up

| US$999.00-49,000.00 | 1 unit (MOQ) |

Basic Info.

Model NO.

TFN 800

Abrasives

Grinding Wheel

Controlling Mode

CNC

Automatic Grade

Automatic

Cylindrical Grinder Type

Plunge Cylindrical Grinder

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Saw Blade Dia

120~810mm

Hook Angle

25°~ -30°

Top Angle

8°~ 30°

Top Chamfer Angle

45°~ -45°

Bore Diameter

12~120mm

Wheel Speed

2500~3500rpm

Grinding Speed

6~30s/Tip

Power

5kw

Weight

3680kg

Voltage

AC 380V-50Hz/220V-60Hz

Item

Tct Saw Blade Sharpening

Function

Top/Face/Notch/Groove Grinding

Application

Carbide Tips Sawblade Sharpening

Application2

Cold Saw Blade Sharpening Machine

Application3

Sawmill

Transport Package

Water Proof + Wood Carton

Specification

2500*1800*2200mm

Trademark

TORSEL

Origin

China

HS Code

8460310000

Production Capacity

5000units/Year

Product Description

TFN800 6-Axes CNC-Controlled Sharpening MachineApplication: This model is designed for cermet tipsTop/Face/Notch/Chip Break Slot/chamfer angle grinding;meanwhile it can be used to sharpen carbide tips with multi-purpose. High precision & productivity is well used for saw blade manufacturer and resharpening service center to process complete angles in 15s-30s with one set sharpener,the precision is controlled <0.025mm.

Features

High-level productivity & Efficiency Grinding machine with higher precision

• Saw Dia: <810mm

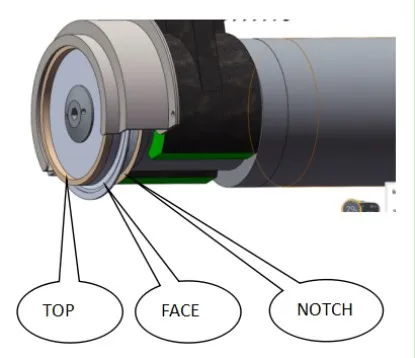

• Function: Tooth Top/Face/Notch/Chip Break Slot/negtive chamfer angle sharpening

• All the angles cycle grinding can be finished in one set-up.

• Precision: <0.02mm

• Efficiency: 4-20s/tip

• High precision, more function & more productivity, PURCHASE is cost-effective.

• Cooperation Company

Advantages of sawblade grinding machine • More precision- grinding precision: <0.02mm,be impressed by the higher accuracy. • More efficiency- experienced productivity on a higher level • More user comfort- simplify your work • More flexibility-for precision in any requirement

• More Function- grinding TOP/FACE/NOTCH/GROOVE/negative chamfer angle of sawblade

Presetting for tooth TOP/FACE/NOTCH grinding

Technical Premeter

| Saw Blade Diameter | 120~810mm |

| Hook Angle | 25°~-30° |

| Top Angle | 8°~ 30° |

| Top Chamfer Angle | 45°~ -45° |

| Face Chamfer Angle | 30°~ -30° |

| Bore Diameter | 12~120mm |

| Pitch | 2~80mm |

| Top wheel size | Φ125mm*Φ32mm*16mm |

| Notch wheel size | Φ125mm*Φ32mm*9mm |

| Face wheel size | Φ150mm*Φ32mm*14mm |

| Wheel Speed | 2500~3500RPM |

| Grinding Speed | 6-30s/tip |

| Power | 5KW |

| Dimensions | 2500*1800*2200mm |

| Weight | 3680kg |

Configuration

| Ball Screw | THK (JAPAN) |

| Crossed Roller Guide | THK (JAPAN) |

| Pneumatic Parts | SMC(Japan) |

| Servo Motor | Inovance |

| PLC | Inovance ARM600 |

| Harmonic Drive | Inovance |

4-axes CNC Controlled with 4 servo positioning system,ensure the angle grinding with higher accurate.

FAQ 1. How to chooce best saw blade grinding machine? - Best grinding machine process tools with higher precision & long service life. 2. How is the performance of TORSEL saw blade grinding machine? - TORSEL saw blade grinding machine process tool with excellent precision <0.01mm,the service life is upto 7-15 years. 3. Whats your cooperation companys?

4. How to do if I can not operate?

If you have operation problem when you get the sharpeners, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side. 5. How to get spare part after warranty

One of our sharpeners is working for Korea Resharpening service for 15 years,we still serve with after sale service.

If buyers need spare parts,or there is any problems after waranty, we will always responsible for TORSEL sharpeners, including find problems, send spart parts, and teach you to replace the parts. .

If you need to learn any information

We are online for your service.

>> Factory Direct Drop Modern Parcel Drop Box Delivery Box Outdoor Steel Mailbox

>> Fixtec High Quality 8PCS Hand Tool Set Electrician Magnetic Screwdriver Set

>> Portable Mobile Phone Repairing Tools Wylie UV Curing Lamp

>> Single Screw Extruding/Extruder Machine

>> Good Price SGCC Dx51d A653 Sgch Q235B Galvanized Steel Corrugated Roofing Sheet

>> Automatic Fruit Vegetable Carrot Pouch Flow Horizontal Packing Packaging Machine

>> 5PCS Microwavable Restaurant Borocilicate Glass Lunch Box Food Bowl Container with Lid

>> Automatic Gypsum Ceiling Board Tile Lamination Machine Production Process

>> 300W 48V 6.3A Constant Voltage Switching Mode Power Supply SMPS

>> Dession small automatic pillow type chocolate pack packing machine for sale factory price

>> Cheap Universal Slant Bed Metal Turning CNC Lathe Machine Tck6340s

>> UCM1100A Industrial High Speed rotary 2 jumbo roll to sheet Automatic Paper Cross Sheeting Cutting Machine cutter

>> Wholesale Chaeum Premium Cross-Linked Hyaluronic Acid for Chin Lip Face Wrinkle Removal Anti-Aging Injectable Dermal Filler

>> Solar Road Cone Light, Solar Warning Light Qh-01j

>> Industry Using Large Loading Capacity Spiral Mixer

>> WTN5400E Adapter′s External 180° Rotatable Antennas Allow for Customizable Network Coverage Tailored to Your Needs LB-LINK WTN5400E RTL8832CU

>> Stainless Steel Flat Pusher Brush Power Tension Constant Force Spiral Coil Compression Extension Torsion Springs for Door Lock Wire Coiled Mechanic

>> Plastic Sheet Production Equipment /Energy-Saving PP Hollow Board Formwork Extrusion Line

>> Factory Custom Skate Board Decking Surf Skate Skateboard

>> Mbm Processing Equipment Poultry Waste Rendering Plant Feather Planting Machine

>> Portable Wireless Mini Stereo Bluetooth Speaker

>> New Agricultural Machinery Workig Width 0.6m 20-25HP Tractor Pto Driven One Row Potato Harvester

>> Horizontal Vertical Heating Cooling PVC UPVC Powder Raw Material Mixer Plastic Blender Hot and Cold Mixing Machine High Speed Mixer

>> Sinotruk Wiper Arm Dz14251740013 for Heavy-Duty Truck Windshield Cleaning System

>> Heavy Duty Large Size Warehouse Spare Parts Industrial Stackable Plastic Storage Bins

>> Horizontal Universal X6132 Made in China High Precision Milling Machine for Sale

>> Custom Design Logo Shoe Strings Personalized Quality Printed Shoelace

>> Hj-2000 Aluminum Alloy Rolling Gate Crusher High Output Equipment

>> Miniature Welding Machine Incorporating Superior Welding Nozzles Laser Features

>> Automatic Plastic Shredder Grinder Crusher Machine Plastic Bottle PP/PE Film Woven Bags Crushing Machines