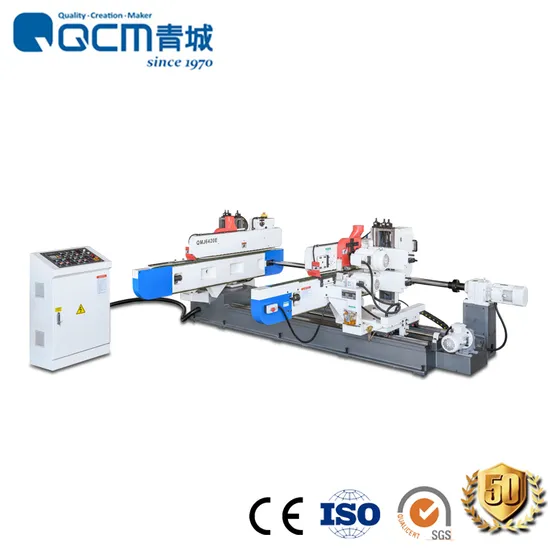

QMJ6420E Double End Saw Woodworking Trimming Machine

| US$18,900.00-19,700.00 | 1 set (MOQ) |

Basic Info.

Model NO.

QMJ6420E

Automatic Grade

Full-Automatic

CNC or Not

CNC

Structure

Horizontal

Product name

Double End Tenoning Machine (8 spindles)

Keywords

tenon mortising

Function

woodworking machinery

Electricity

Siemens

Machine body

Casting

Voltage

380v, Can be customized

Cutter Head

Spiral cutter spindle, Can be customized

Core Components

Engine, Bearing, Gearbox, Motor, etc.

Certificate

CE & ISO

Machinery Test Report

Provided

Place of Origin

Sichuan, China

Application

Wood flooring, wooden door, panel furniture

Applicable Industries

Woodworking factories, Sawmill

Professional solution

Double end trimming and tenoning for thick wood

Fit for making

Solid wood furniture and building templates, etc.

Transport Package

Plywood Carton

Specification

4100*2500*1450 mm

Trademark

QCM, Smart Panther

Origin

China

HS Code

84659100

Production Capacity

1000 Units/Month

Packaging & Delivery

Package Size

410.00cm * 250.00cm * 145.00cm

Package Gross Weight

3000.000kg

Product Description

QMJ6420E Double End Tenoning Trimming Machine Woodworking Machinery Made In China Factory Manufacture Tenoner Mortising Product Parameters| Technical Parameter | |||

| Model | Double End Tenoning Machine | Unit | QMJ6420E |

| Specifications | Processing width | mm | 230-2000 |

| Processing thickness | mm | 10-60 | |

| Feed block spacing | mm | 400 | |

| Feeding speed | m/min | 6-24 | |

| Drunken saw speed | r/min | 3000 | |

| Amputating saw speed | r/min | 3000 | |

| Left, right drunken saw diameter | mm | Φ160-Φ200 | |

| Left, right amputating saw diameter | mm | Φ250-Φ300 | |

| Drunken saw spindle diameter | mm | Φ30 | |

| Amputating saw spindle diameter | mm | Φ30 | |

| Motor Power | Total motor power | kW | 15.35 |

| Left, right drunken saw motor | kW | 2.2*2 | |

| Left, right amputating saw motor | kW | 4*2 | |

| Feeding motor | kW | 2.2 | |

| Width adjusting motor | kW | 0.75 | |

| Pressure & Diameter | Vacuum port diameter | mm | Φ120 |

| Dimensions & Weight | Overall dimensions | mm | 4100*2500*1450 |

| Weight | kg | 3000 | |

Product Main Features

1. This machine adopts integral casting body with stable performance, good precision and good rigidity.

2. Siemens and Schneide electrical products and appliances insure the whole machine run well with a stable performance.

3. Feeding guide rail is cast with sectional combination structure. 1300mm long feeding area has a feature of easy assembling, stable precision, especially suitable for large size work piece.

4. Worktable width movements uses imported linear guide and CNC automatic width setting structure which has feature of easy adjustment, precise positioning and excellent wear ability.

5. Up pressing mechanism is configured with NC electric lift, ensuring the stable pressing and more convenient and quick

operating.

6. The operating system is equipped with an imported computer touch screen and PLC for joint control, which is intuitive and convenient to operate, which can effectively reduce adjustment time and improve production efficiency.

7. Feeding chains are configuration with high precision synchronous chain, aluminum alloy chain plates and rolling bearing structure, ensuring the stable running, accurate positioning, stable and reliable.

Product Description

Company Profile

About US

QCM Machinery was established in 1970 and have been specializing in production of woodworking machinery for more than 50 years now.

We have our own casting workshop, and more than 300 sets of modern CNC machining equipment and testing equipment, such as Okuma, Mazak, Mitsubishi. Strong R&D team with 55 people can provide our customers with the biggest professional technical support.

Choose our machinery, to help you improve productivity, processing quality, and profit.

Advantages and Service

1. Lead Time?

Within 15 days for regular stock machine after receiving down payment.

45-60 days for customized machines,

60-90 days for busy season.

2. Warranty ?

3 years for machine, 3 years for the core components.

3. Spare Parts?

Unified standards spare parts are available anytime.

4. Voltage?

Regular voltage 380v, 50hz; customized voltage is available.

5. After-sale Service?

24 hours technical support by email, call and video.

our engineer is available to visit at your expenses of accommodation and round tickets.

6. Why us?

1). 50 years experience in woodworking machinery since 1970.

2). Our own casting workshop to insure extra heavy one-piece cast iron machine body for maximum stability and rigidity. Control quality from raw material.

Click on the image below to view more : )

Contact Us

>> Used Volvo 80 Crawler Excavator for Manufacturing Plant

>> 100% Polyester Linen Upholstery Fabric Sofa Fabric Flocking

>> New Woman Coat Loose Plaid Color Knit Cardigan Sweater

>> Label Packaging Box Decoration Arts and Crafts 2513UV Flatbed Printer

>> 3.2mm Customized Shape Anti-Reflective Non Reflective 93 % 94% AR Glass For showcase

>> ZICAR automatic woodworking cutting precision saw

>> Hand Push Tilling Machine Gasoline Mini Tiller Cultivator

>> China Recommended Essential Oil Distillation Equipment Machine

>> Armor Safety Bump Cap Black/Red with Reflectve Tape for Day/Night Use

>> 5% off Pd30W Two Car Charger One Point Two Cigarette Lighter Dual USB Fast Charge QC3.0 Truck General

>> High Speed Wholesale CNC Turning Lathe Machine Supplied by Physical Manufacturers Tck56-500

>> Heavy-Duty Plastic Medical Waste Management Disposal Bags for Biohazard Waste Management

>> Chinese Factory Custom Designed to Produce Wholesale High Quality Military Academy Navy and Army Soldiers Competition Metal Crystal Solid Wood Trophy Awards

>> High Speed Automatic Wood Stringer Pallet Notching Machine for Pallet Factory

>> Factory direct non-standard chamfered flat head hexagon socket straight repair screws

>> Basketball Stand Basketball Stand Standard Size Portable Steel Basketball Stand

>> Expanded Metal Bookcase

>> Personalized Suit Dust Foldable Long Wedding Dress or Covers Clothes Protector Garment Bag

>> 58 Inch 2-PC Carving Maple Billiard Cue Stick

>> Mini Auto Portable Ejector Knife Flick Knife Blade Pocket Outdoor Otf Knife

>> Diesel Common Rail Fuel Injector Denso 095000-9560 1465A257 Is Suitable for Mitsubishi Engine

>> Yonthin High Speed Computer Double 2 Heads Cap Monogram Embroidery Machine Computerized 3D Logo

>> High Precision Pd2016 Gantry Type CNC Metal Router Drilling Milling Tapping Machine

>> Slfw-a Honeycomb Paper Forming Machine

>> YFXF-90 factory price automatic multi-stage incubator price malaysia

>> EPS EPE Plastic Foam Crushing Recycling Machine Cold Press Compactor

>> Home Appliance Cooktops Burner Gas Hob Stainless Steel Gas Stove

>> Land Leveling Laser Land Grader / Leveling Machine / Leveler

>> Charcoal ball briquette making pressing forming machine

>> American style up and down sliding double hung windows glass aluminium top single hung window