Customized 3/4/5 Axis Vertical Machining Center for Metal Cutting

| US$28,500.00-62,900.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LJ-1270B-2T

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools, Metal-Forming CNC Machine Tools

Numerical Control

CNC/MNC

Performance Classification

High-End CNC Machine Tools

Certification

GS, CE, RoHS, ISO 9001

Condition

New

X/Y/Z-Axis Travel

1200/700/680mm

Spindle Nose to Table Distance

120-820mm

Max Load Capacity

800kg

Max Spindle Speed

8000rpm(Optional Direct Drive: 12000)

Transport Package

Steel Box

Specification

Customized products

Trademark

GooDa

Origin

China

HS Code

8459619000

Production Capacity

500sets/Year

Packaging & Delivery

Package Size

310.00cm * 300.00cm * 300.00cm

Package Gross Weight

7000.000kg

Product Description

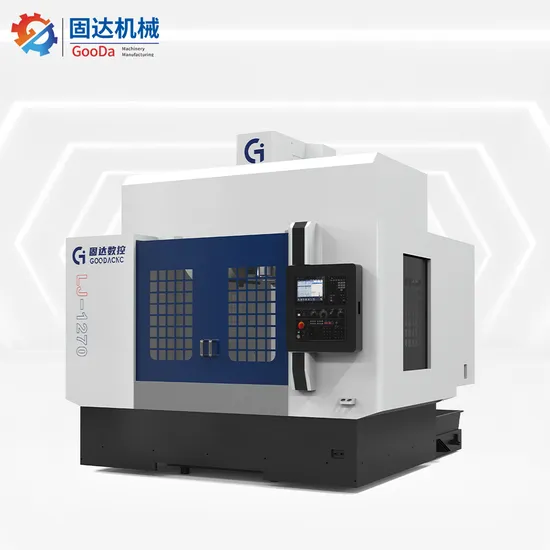

Main FeaturesGooDa Vertical Machining Center with Dual Tool Magazine LJ-1270B-2T:

Crafted with a sophisticated design, it boasts the versatility of two linear and one hard rail or the option of three linear rails, seamlessly integrated with a dual tool magazine operation.

This powerhouse not only excels in high-efficiency machining of standard panel components, but is also meticulously engineered to tackle the intricacies of machining complex workpieces with unmatched precision.

Main Functions

- Multi fixtures for small-batch machining, ensuring flexibility and precision.

- Dual tool magazine with an impressive capacity of 64 tools for relentless efficiency.

- Equipped with THK linear rails and ball screws, guaranteeing smooth and accurate transitions.

- Anti-collision tool setter for enhanced safety and reliability.

- Dual tool magazine and multi fixtures for versatile functionality.

- Seamless, programming-free tandem operation for user-friendly experience.

- Quick clamping mechanism for swift and secure adjustments.

- Engineered for high efficiency and remarkable speed.

- Features a renowned Taiwan brand spindle for superior performance.

Product Parameters

| Model | LJ-1270B-2T | ||

| Category | Attribute | Value | Unit |

| Worktable | Worktable Size | 1300×700 | mm |

| Max load capacity | 800 | kg | |

| Number of T-slots - Slot Width × Spacing | 5 slots - 18×100 | mm | |

| Travel | Three-axis Travel (X/Y/Z) | 1200/700/680 | mm |

| Spindle Nose to Table Distance | 120~820 | mm | |

| Spindle | Spindle Taper | BT40# | - |

| Spindle Motor Power | 7.5/11 | Kw | |

| Spindle Drive Method | Belt Drive (Optional: Direct Drive) | - | |

| Max Spindle Speed | 8000 (Optional Direct Drive: 12000) | rpm | |

| Feed | Rapid Traverse Speed (X/Y/Z) | 24/24/16 | mm |

| Cutting Speed (X/Y/Z) | 1~12000 | mm/min | |

| Tool Magazine | Number of Tools | 2×32T Robot Arm | T |

| Max Tool Weight | 8 | kg | |

| Accuracy | Positioning Accuracy (X/Y/Z) | ±0.005/300 | mm |

| Repeat Positioning Accuracy (X/Y/Z) | ±0.003/300 | mm | |

| Other | Electrical Capacity | 25 | KVA |

| Overall Dimensions (L×W×H) | 3.1×3.0×3.0 | m | |

| Weight (Approx.) | 7000 | kg | |

Our dedicated team of experts stands ready to guide you in selecting the most suitable machine for your unique processing requirements. Get Expert Assistance Now! Examples of Processed Parts

Quality Control

Roughness measurement of table surface using a state-of-the-art roughness tester.

Spindle dynamic balancing test ensures impeccable processing accuracy and performance.

Spindle pull force testing to precisely measure spindle tension and ensure optimal operation.

All machines must pass a rigorous coordinate measuring machine (CMM) inspection before leaving the factory, ensuring the highest standards of quality and precision.

Company Profile

Factory Display

Certifications

FAQ

Q1. What is your minimum order quantity and warranty?

A1: MOQ is one set, and the warranty is 12 months.

Q2. What CNC system do you use?

A2: FANUC, SIEMENS, MISTSUBISHI, etc. It depends on your choice.

Q3. When is the delivery time?

A3: For conventional machines, we will deliver them within 30-45 working days after receiving your deposit; For special machines, the delivery time may be longer, and we will provide you with an updated timeline accordingly.

Q4. What is the packaging for the machines?

A4: Packaging: PE bag cover (inside), plywood box, and steel beam frame. Other packing methods are also available.

Q5. How can I select the most suitable machine?

A5: Please let us know your machining requirements or the machine size, and we can recommend the best model for you.

Alternatively, you can choose the exact model yourself. You can also provide us with the product drawings, and we will help you select the most appropriate machine.

Q6. What are your trade terms?

A6: FOB, CFR, CIF, or other terms are all acceptable.

Q7. What are your payment terms?

A7: We accept T/T with a 30% deposit when placing the order and the remaining 70% balance before shipment.

We also accept an irrevocable letter of credit (LC) at sight.

Production will begin once we receive the advance payment. When the machine is ready, we will send you pictures. After receiving the balance payment, we will proceed with the shipment.

Q8: Are you a manufacturer or a trading company?

A8: We are a combined manufacturing and trading company, specializing in the innovative development and production of machine tools, with extensive experience in global exports. We warmly welcome you to visit our factory.

Q9: Can you provide OEM services?

A9: Absolutely. We are happy to create a customized plan based on your requirements and offer the best service to meet your needs.

Q10: How can we receive training for the machines?

A10: You can send your team to our factory for free training, or we can arrange for one of our engineers to travel to your location for on-site training.

>> Economic CNC Gear 4-Axis Hobbing Machine Max Dia 280mm Workpiece, 1-3 Module Range

>> Xingpai Brand Multi-Layer Three Layer Co-Extrusion LDPE HDPE PE Film Blowing Machine Plastic Extruder Biodegradable Plastic Blown Film Extrusion Machine

>> AAA Quality 100% Garanty Top Selling Mobile/Cell Phone LCD for Samsung Note 20/Note 10/Note 9/Note 8/S22/S22 Plus/S22 Ultra/S21/S10/S10 Plus/S9/S9 Plus/S8 G950

>> All Tag Security 58kHz EAS Am Tag

>> Hot Sale Multi Function Korean Premade Bag Food Vacuum Sealing Meat Product Making Packing Machinery Meat Packaging Machine

>> Chicken House Light Trap Light Filter for Exhaust Fan

>> Soft Summer Home Cotton Linen Slipper Unisex Comfotable Slipper Sandal

>> New Solid Ribbon Split Swimwear

>> Hot Sale China 4L~30L HDPE Jerry Cans/Bottles Blow Molding Machine

>> JOHNCOO New Soft Worm Bait Fishing Lure Worm Soft Baits Silicone Fishing Tackle Set

>> Pre-Seasoned 7 Piece Heavy Duty Cast Iron Dutch Oven Camping Cooking Set with Vintage Carrying Storage Box

>> 316L Stainless Steel Wire Cut Resistant Work Safety Glove

>> Custom design Youth American Football Team uniforms

>> Waterproof 3000K 4000K 6000K Oem Cob Spotlight Zinc Round Outdoor P8 P10 Screen Die Casting Aluminium Body Led Light Housing

>> Hot Selling in Southeast Asia CE Certified Xy-442 Electric Waist Massager Massage Equipment

>> ME016823 Mitsubishi Fuel Filter for Cars

>> High Efficiency 800 kVA Oil-Immersed Distribution Transformer Three Phase Electrical Transformer

>> Customized Wood Chipper Blades for Wood Saw Machine

>> 2024 New Arrival Powder Texture Smooth Non Oil Easy Blend Lovely Cheek Custom Logo Face Make up Cute Powder Blush Stick

>> 10- 25m3/H Mobile Concrete Mixing Plant From Sddom for Construction (MC1200)

>> Highly Recommend HVAC Duct Production Line 4/Rectangular Tube Forming Machines Made in China

>> Rehau brand PVC profile casement window German PVC window design

>> Factory Direct Automatic CNC High Quality Wire Cutting Machine 2.5-5.5mm

>> Jieda PD800 Model Hanging Bag Large Volume Centrifuge

>> Dental Micro Brush Disposable Micro Applicator

>> SHENGKE SK Classic Minimalist Watch Ladies Watch Woman Quartz Alloy Watch Gray Leather K0056L

>> HDPE 7 Diameter Rod Plastic White Blue Yellow HDPE Bar Unlimited Custom Size Rod

>> Copper Wire Iron Steel Crusher Rubber Scrap Tyre Recycling Equipment Tire Shredder Machine Prices

>> High-Quality Tube Welding Machine for Efficient Production Processes

>> Aluminum Solar Panel Carport Mounting PV System Carport Mounting Solar