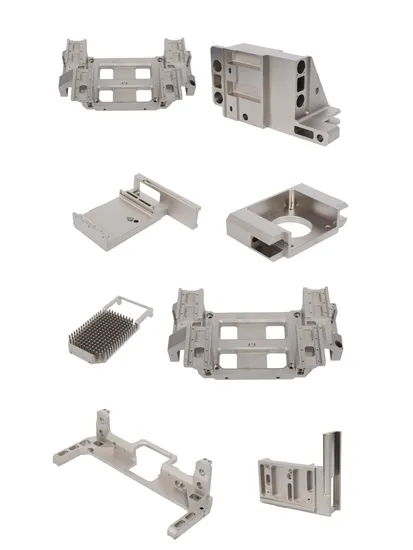

Precision CNC Machining Die Casting, Aluminum Casting for Auto Components

| US$1.00-10.00 | 100 Pieces (MOQ) |

Basic Info.

Model NO.

mm

Condition

New

Certification

ISO9001

Standard

GB

Customized

Customized

Material

Aluminum

Application

Metal Casting Machinery

Turnaround Time

Around 30-50days

Applicable to

Machine Components

Characterization

High Corrosion Resistance

Transport Package

Box

Specification

100*100*100

Trademark

BSK

Origin

China

HS Code

7616991090

Production Capacity

3000

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 50.00cm

Package Gross Weight

2.000kg

Product Description

Die casting manufactureProduct Parameters

| Material | Aluminum /Zinc Alloy |

| Pressure Chamber Structure | Horizontal |

| Casting Surface Quality Level | 1 |

| Equipment | 160T-630t Casting Machine |

| Type of Material | A356.2 |

| Advantage | High-Strength High Density |

| Transport Package | Carton |

| Trademark | BSK |

| HS Code | 7616991090 |

| Machining | CNC Machining |

| Surface Preparation | Deburring |

| Tolerance Grade | 6 |

| Certification | ROHS, IS0 9001:2015 |

| Surface | Trimming, Deburring, Polishing,Shot Blasting |

| Process | Pressure casting |

| Description | Aluminum Die Casting |

| Specification | OEM |

| Origin | SHENZHEN |

| Production Capacity | 1000tons/Month |

| Process | Aluminum Die casting, Gravity Casting, Zinc Die Casting,CNC Machining, In-house Tooling |

| Equipment | Cold chamber aluminum die casting &hot chamber Zinc die casting160T/400T//500T/630T CNC machining centers, CNC gantry machining centers, CNc turning, CNC lathes, CNC miling, CNc driling, CNc grinding, and EDM machines. |

| Material | For Aluminum Die Casting: A319,A356, A360, A369,A380,A383, A384,A413,A535,44300,44300,46000,AISi9MG, AISi9Cu3 Material ADC12,ZL102, ZL104,ZL108,Zamak2,3,5,7 etc |

| Product Applications | Automotive, Bicycle, Motorcycle, Aerospace, Machinery, Household, Electric Appliances, Oil and Gas, Fluid Control,LED Lighting,Medical Instruments, Telecom, etc. |

Company Profile

Huizhou Baishengke Precision Technology Co., Ltd

Company Profile: Introducing Huizhou Baishengke Precision Technology Co., Ltd., a trailblazer in the precision manufacturing industry. Founded back in 2001 and originally known as Shenzhen Baishengke Precision Industry Co., Ltd., we've established a robust foundation in the picturesque Zhenlong Town, Huizhou City, renowned for being the 'Home of Lychee'. Our sprawling 11,000 square meter facility is a hub of innovation, employing a passionate team of over a hundred skilled professionals dedicated to excellence.

Our company is a powerhouse in the production of a vast spectrum of high-precision products. We specialize in aluminum and zinc alloy die-casting, cutting-edge mold design and manufacturing, CNC machining, sophisticated injection-molded products, hardware components, and impeccable metal stamping parts.

Armed with the latest in production technology and a team of highly skilled technicians, we are unwavering in our commitment to our business ethos of 'integrity, quality, service, and innovation'. Our mission is to deliver exceptional products supported by our philosophy that 'integrity creates quality, professionalism shapes the future'. Our strategic marketing endeavors and unparalleled service systems have fortified our reputation, earning the unwavering trust and acclaim of clients both domestically and globally. We proudly serve dynamic industries such as information technology, semiconductor equipment, communication security, electronics, and automotive parts manufacturing.

Our Advantages

Distinctive Advantages of BSK

>> Over 23 Years of Manufacturing Excellence

>> 3 State-of-the-Art Manufacturing Bases

>> In-House Mold Crafting Expertise

>> Rigorous Quality Assurance: ISO 9001 Certified

>>80% Products Exported Globally

>> Offering Comprehensive Solutions: From Design to Mold Development to Casting to CNC Machining to Surface Treatment to Assembly and Packaging

1.Exceptional Design and Research Proficiency

Our team includes 8 seasoned R&D experts, specializing in mold design and technical evaluation. Their extensive experience, exceeding a decade in stamping and CNC machining, ensures top-notch solutions.

2.Pioneering Independent Research and DevelopmentWe boast our own advanced processing equipment, empowering us to conduct independent R&D, thorough manufacturing, and stringent quality control within our production system.

3.Meeting Diverse RequirementsWith over three decades of experience in precision machining, we excel in crafting sophisticated equipment. Our facility is equipped with high-precision Japanese-imported machine tools, milling machines, and grinders, achieving machining accuracy up to +0.005mm, solving critical challenges in high-precision equipment processing for our clients.

4.High-Efficiency Completion RateUpon receiving customer orders, we ensure prompt responses, providing samples within 20-30 days and completing batch production within 10-20 days.

Core Business Areas

Die-Casting Products:

Intricate Complex Geometry : Die-casting transforms metal into intricate and complex forms, achieving unparalleled shapes that other manufacturing methods cannot replicate.

Exceptional High Strength : Die-cast products boast outstanding strength-to-weight ratios, making them ideal for applications requiring high durability.

Impeccable Surface Finish : Die-casting delivers superior surface finishes, significantly reducing the need for extensive post-processing and machining.

Highly Cost-Effective : Die-casting is highly efficient for mass production, with impressive production rates and minimal labor costs per unit.

Material Versatility Scope : Die-casting accommodates a diverse range of metals and alloys, such as aluminum, zinc, and magnesium, offering extensive material selection flexibility.

CNC Machining:

Unrivaled Precision and Accuracy : CNC machining stands as a paragon of precision, ensuring high accuracy and maintaining stringent manufacturing tolerances effortlessly.

Remarkable Versatility : It excels in creating a vast array of parts with intricate geometries, ideal for both prototypes and full production runs.

Exceptional Repeatability : CNC machining guarantees unmatched consistency, precisely replicating each part per meticulous digital designs.

Design Flexibility : CNC machining allows seamless design modifications, accommodating quick changes through simple CNC program updates.

Superior Automation and Efficiency : The inherent automation in CNC processes reduces labor costs and minimizes human error, leading to efficient production and shortened lead times.

Exceptional Quality Control : Our state-of-the-art CNC machines are meticulously equipped with advanced measurement and inspection tools, ensuring the delivery of superior, high-precision finished products.

Both die-casting and CNC machining are absolutely indispensable in industries that demand uncompromising precision, including automotive, aerospace, electronics, and consumer goods manufacturing.

Manufacturing process

State-of-the-art Testing Equipment

| Our Quality Inspection Instruments | |

| Dimensions and Tolerances | Coordinate Measuring Machine (CMM), Micrometer, Vernier Caliper, Full Range PinGauge/Gauge |

| Mechanical Properties (Strength, Hardness,Density) | Tensile Testing Machine, Hardness Tester, Density Tester |

| Internal Structure (Porosity) | Ultrasonic Testing, Destructive Testing,apperance inspection |

High-Resolution Product Image

Detailed Photos

Company Display: A Glimpse into Our Excellence

Packaging & Shipping

Certifications

FAQ

FAQ:

Q: What kind of files can you read?

A: We gladly accept a wide array of 2D and 3D drawings, embracing formats like PDF, DWG, DXF, IGS, STP, X_T, and beyond. This flexibility ensures we meet all your design needs with precision.

Q: How would you maintain superior quality control?

A: At every stage of our meticulous manufacturing process, we implement rigorous inspections. Our commitment to excellence involves comprehensive checks during production, combined with detailed final inspections prior to shipment, ensuring that we deliver unparalleled quality.

Q: What is the process for customizing products?

A: To initiate a custom product, please provide detailed drawings that encapsulate specifications like material type, surface treatment, desired quantity, along with any unique requirements you may have.

Q: How does Huizhou Baishengke Precision Technology Co., Ltd ensure quality control?

A: Our robust quality control measures are reinforced through the use of advanced professional equipment. We employ CMM, height gauges, calipers, micrometers, ultrasonic fault detectors, hardness testers, spectrum analyzers, impact testing machines, and sophisticated quadratic equipment to achieve precision inspection.

Q: What is the Minimum Order Quantity (MOQ)?

A: Our flexible MOQ policy ranges from just 5 to 1000 pieces, and we also offer sample orders to cater to your specific needs.

Q: Are you able to create castings based on our samples?

A: Certainly. We possess the expertise to take accurate measurements from your samples, allowing us to craft detailed drawings which serve as the foundation for tooling production.

Our efficient process requires a turnaround time of 30 days for each case, ensuring your project is handled with timely precision.

>> Hydraulic Lifting Disperser Water Based Paint Vacuum High Speed Disperser Mixer Manufacturer

>> Top Quality Customized Best Selling Paper File Folder Paper Binder

>> Food Grade Homogenizer High Shear Batch Mixer

>> Professional Production Sepiolite Powder Sepiolite Velvet for Manufacturing Paint and Insulation Mortar

>> Fashion Designer Top Handle Hand Bags Tote Replicas Luxury Handbags Lady Crossbody Chain Shoulder Bag

>> Concrete Block Making Machinery for Construction

>> 1-2 Tons Tractor Winch / Forest Winch / Pto Winch

>> ODM Single-Tool Holder CNC Heavy Duty Machine Lathe Engraving Machines

>> JOHNCOO Wholesale Outdoor Fishing Portable Aquarium Oxygen Pump Breeding illumination Oxygen Air Pump

>> High-Precision CNC Automatic Machining Center for Efficient Production

>> High Quality PTFE Material Plastic Rod China Supplier

>> Pet Plastic Medical Disposable Needle Injection Making Moulding Machine Price

>> Portable Power Screw Drivers Battery Folding-Type Electric-Drive Screwdriver

>> Woodworking Machinery 6heads Four Sided Moulder Four Side Planer

>> Nexara HDPE Racking Load Flat Surfacethree Runner Euro Logistics Pallet

>> Handheld Fiber Laser Welding Machine 1500W Aluminum Copper Galvanized Steel Water Cooled

>> 2009 2013 custom 3 pieces led lights honeycomb black front grille fit for dodge ram 1500

>> Customized Barmag Al2O3 Shaft Parts/Alumina Ceramic Bar

>> 1092mm 2t/D Single-Cylinder & Single-Wire Toilet Tissue Paper Making Machine

>> Tadm3635 High Quality CNC Drilling Machine for Angle Bars

>> Window Screen Mesh Durable and Easy to DIY Screen Roll for Window

>> High-Quality Boron Steel Plough Harrow Disc Blade for Agriculture

>> Mechanical Seal TM3/M3a

>> High Quality 5V Horizontal Vertical Universal Turret Milling Machine for Metal

>> Sustainable Medoo Non-Slip Capped Overstock WPC Outdoor 3D Deep Embossed Composite Deck Tile Decking

>> Kurimoto Twin Screw Extruder Screw Elements Diameter 400 for Petrochemical Factory

>> Aroma Sachet, Linen Fabric Bag, Nature Inspired Gift Pouch, Bulk Bag, 5X7"

>> Gas Station Stainless Steel Gauge Ex IP68 Fuel Level Sensor

>> Baby Cozy Toys Kids Delightful Gift - Adorable Green Animal Plush

>> Big Bore Heavy Duty Precision Horizontal Metal Lathe Machine