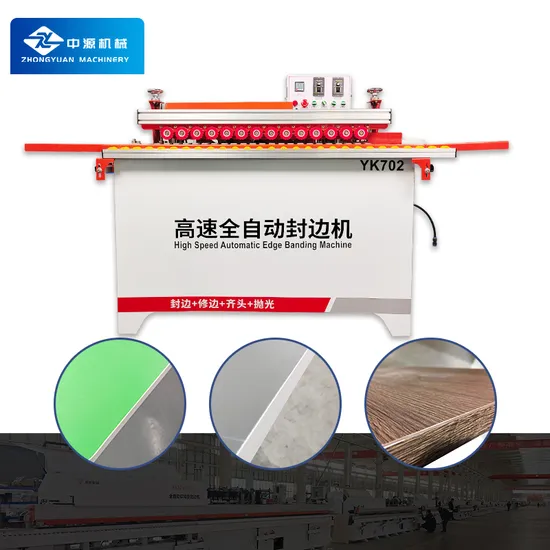

High Speed Edge Bander Machine Woodworking PVC Edgebander Machine Price Wood MDF Laminate Edge Banding Machine

| US$730.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

YK702

Type

Automatic Edge Banding and Trimming All-in-One Mac

Automatic

Automatic

Certification

CE, ISO

Model

Yk702

Supply Voltage

220V/50Hz

Rated Power

3.8kw

Capacity of Glue Pot

1000ml

Trimming Height

0-50mm

Sealing Height

5-50mm

Heating Time

5-10min

Edge Sealing Speed

0-7m/Min

Gluing Method

Double-Sided Gluing

Net Weight of Machine

105kg

Standard Size

1200*550*1100mm(L*W*H)

Transport Package

Wooden Box

Specification

1200*550*1100mm

Trademark

YinTai

Origin

China

Production Capacity

100sets/Month

Packaging & Delivery

Package Size

120.00cm * 55.00cm * 110.00cm

Package Gross Weight

105.000kg

Product Description

Product ParametersHigh-speed Automatic Edge Banding Machine:

High-speed fully automatic edge banding machine: This machine has anintegrated pressure beam design, siliconetransmission belt, straight-linedouble-sided gluing, large-capacity qlue pot, automatic feeding/breakingcuttingend, vacuum cleaner and double-sided polishing, perfect edgebanding effect.

| Model | YK702 |

| Supply Voltage | 220V/50HZ |

| Rated power | 3.8KW |

| Capacity of glue pot | 1000ml |

| Trimming height | 0-50mm |

| Sealing height | 5-50mm |

| Heating time | 5-10min |

| Edge sealing speed | 0-7m/min |

| Gluing method | double-sided gluing |

| Net weight of machine | 105kg |

| Standard size | 1200*550*1100mm(L*W*H) |

Detailed Photos

Product Application

Company Profile

Certifications

FAQ

Q1: I already have an edge banding machine and I would like a trimming machine. Do you have any recommendations?

A: Yes, we have a matching trimming machine. You can choose the product that suits you according to your actual production needs. Of course, we will also ask you some questions, such as plate size, plate thickness, equipment voltage, number of workers, and so on. With so many types of products, there is always one that is suitable for you.

Q2: Can your edge banding machine use PUR adhesive?

A: PUR glue has high requirements for glue pots. We recommend using models such as F14620-3700-3350 for up glue pots, depending on your specific needs.

Q3: Are you a factory or a trader?

A: We are a 20 year source production factory with rich production experience and a total of 8000+customers. We can provide you with thoughtful and accurate after-sales service.

Q4: How should I make the payment?

A: Firstly, you will pay a 50% deposit as a prepayment, and then we will start producing the equipment. After the equipment is completed, I will send you photos and videos, and you can make the remaining payment. After receiving all the payment, we will arrange for the fastest container to ship to you. You will receive the equipment soon, and I will arrange professional technicians to coordinate with you regarding installation issues.

Q5: How long is the delivery time?

A: Conventional equipment takes 10-12 days, customized voltage or other parameters take around 30-45 days.

>> for Honda Motorcycle Accessories and Parts 2020-2023 Sh Motorcycle Fairing

>> Waterproof nonwoven disposable hulf elastic waist ppe coverall workwear with hood

>> Newest Outdoor Indoor Summer Toys Bubble Gun Machine Toy for Kids

>> Regulate hormone levels,remove toxins from the body physical therapy apparatus

>> Engine Use Thermostat, Truck Man Engine 5435

>> 16 Oz Amber Boston Round Pet Bottle with Screw Cap

>> Grs Recycled 50s/2 High Speed Sewing Thread Yarn Raw White Top Quality

>> 2022 Industrial automatic coal dust briquetting machine egg shape briquette machine hot sale

>> 22m Articulated Boom Lift with CE (GTZZ22Z)

>> 20L 25L Plastic Jerry Can Blow Molding Machine

>> Mobile Electric Toaster Polymer Clay Oven Baking Model Bread Snack Food Oven Gas Electric Baking Silicone Baking Mat Dutch Oven

>> Custom metal Stainless Steel Perforated Sheet for windbreak wall

>> Empty 3oz 5oz 8oz 90ml 150ml 250ml Clear Round Salad Hot Sauce Glass Bottle with Cap

>> Yoga Back Roller Massager Sport Strong Load Bearing Capacity Custom Foam Roller

>> OEM Plastic Juce Bottle Making Machines

>> GLS63 AMG GL450 500 4MATIC Rear Lamp Tail Light for GL Class W166 1669060202

>> Truck Air Filter Making Machine Air Filters Production Pleating Machine Pleating Machine Full-Auto Knife Paper Pleating Machine

>> Hydraulic Lifting Equipment Work Platform (8m)

>> Waste Plastic Bottle Washing Machine Pet Flake Recycling Machine

>> Portable 4X4 12000lbs Offroad Car Electric Winches

>> Laboratory Microscope Cleaning Paper 15 X 10cm 50 Sheets Disposable Microscope/Camera Lens Tissues Lens Cleaning Tissue

>> Plastic Film Slitting Machine Slitter Rewinder Machine BOPP PVC Film Slitting Machine

>> New design 100g - 250g Automatic sachet Shisha Charcoal tablets packaging machine

>> RDL25C FINCM Attractive Price New Type CNC Rails Drilling Machine

>> Gorilla Bottle Ecigarette Filling Capping Labeling Line Machine

>> Eco-Solvent Chemical Fiber in Roll for Matte Blank Inkjet Printing Painting Canvas

>> Topkit Tower Crane with CE Centification Tc7040-16t

>> High Capacity Tmr Feeding Mixer with Low Price

>> Toptooling Custom Plastic Injection Mold Parts for Children′s Toy Production

>> New style Universal carbon fibre chrome exhaust tip for porsche 14-16 Macan Round Chroming Black