100t Bolte Type Fly Ash Cement Powder Silo for Sale Price

| US$9,800.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

VCS-100

Type

Cement Storage Equipment

Feeding Height

2m

Certification

ISO9001: 2000, CE

Condition

New

Color

as Per The Requirement of Client

Discharging Height

5m

Container Needed

4 Sets in One 40FT Container

Safety Valve

Included

Dust Collector

Included

Level Indicator

Included

Transport Package

Container

Specification

100t

Trademark

Shengmao

Origin

China

HS Code

73090000

Production Capacity

30 Sets/Month

Packaging & Delivery

Package Size

1150.00cm * 220.00cm * 250.00cm

Package Gross Weight

4500.000kg

Product Description

Vertical cement siloHorizontal cement silo

Mobile horizontal cement silo

Product Description

1. Brief introduction of our cement silo

Traditionally, we use cement silo to store dry powder material like cement, fly ash etc. It is usually equipped with accessories like filter, level indicator, flow promotion device, safety valve to ensure it works efficiently and environment friendly. Vertical cement silo is a key part of concrete batching plant.

Currently, we can produce 20T to 2000T cement silo in welding type or bolted type. Welding type cement silo is easy to install but inconvenient for transportation; While bolted type cement silo is convenient for transportation but time-consuming for installation.

2. Components of our cement silo

1) Vertical cement silo body which is usually made of carbon steel Q235;

2) Dust collector on the top of cement silo;

3) Safety valve;

4) Inside and outside ladders;

5) Level indicator;

6) Support legs;

7) Load cell on support legs;

8) Penumatic flow promotion device;

9) Manual butterfly valve;

10) Cement feeding pipe.

3. Features of our cement silo

1) Several measures are taken to make sure the cement silo is water-proof. Such as carbon dioxide welding, glass cement etc.

2) Primer and top coat are used to make sure the cement silo surface is antirust;

3) Safety valve is used to protect the cement silo when it is blocked and the inside pressure increases quickly;

4) Cement silo top dust collector is used to protect the environment;

5) Level indicators or load cell are used to let us know the quantity of cement inside cement silo;

6) Pneumatic flow promotion device is used to facilitates the discharging of cement;

7) Inside and outside ladders are equipped to help workers maintain the cement silo.

8) Our new technology can save much shipping space for clients (4 sets100t cement silo can be put into one 40HQ container).

4. Delivery of our cement silo

1) For welding type cement silo, the Max. capacity that can be put into 40HQ container is 50T;

2) For bolted type cement silo, even 2000T cement silo can be put into container;

3) For welding type cement silo, if the capacity is more than 50T, we can use break bulk vessel or flat rack container to deliver it, but the cost is much more expensive than that of the 40HQ.

Product Parameters

Specification of 100t cement silo

| Model | 100T |

| Silo Diameter (A) | 3,000mm |

| Silo Body Height (H1) | 9,924mm |

| Silo Cone Height (H2) | 2,350mm |

| Silo Height (H3) | 16,274mm |

| Total Height (H4) (including handrails) | 17,274mm |

| Discharging Height (H5) | 4,000mm |

| Material | Q235 |

| Steel Thickness (from Cone to Top) | 5-4-3-3-3-3-3-3mm |

| Accessories | Dust Collector, safety valve, Handrails, Inside& Outside Ladders, Inlet Tube, Butterfly Valve, Support Legs, Arch Breaking |

Detailed Photos

Pictures of our cement silo

1) Welding type cement silo

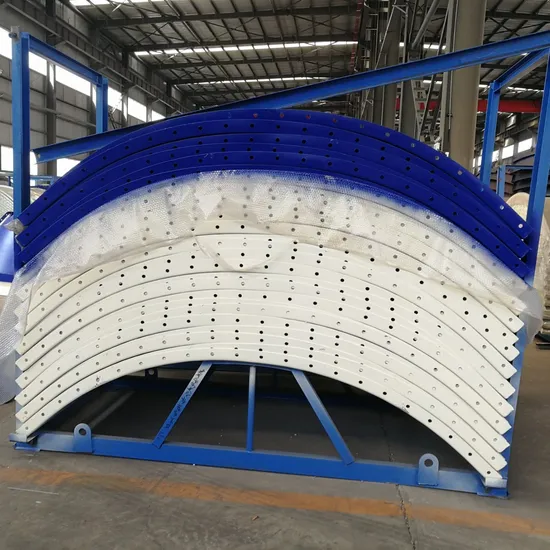

2) Bolted type cement silo

Certifications

CE certificate

>> Stone 1530 CNC Engraving Machine

>> Automatic Eyelet Pressing Machine for Pressing Eyelets Tightly on Fabrics

>> Noble PU Leather Single Watch Box with Led Light

>> Xdl19-F21-3 Wireless Push Button Waterproof 12 V Push Button for Industrial Control

>> Canwell Posterior Thoracolumbar Spinal Fixation System Titanium Spine Pedicle Screws

>> HDPE Heavy Duty Dura Deck Plates/HDPE Dura Mat Ground Cover

>> WEIKA Nice windows Latest Design UPVC Frame Swing Window

>> UC-V4 Tractor Fuel Pump

>> Container Good Loading Ramp Hydraulic Dock Leveler with Manuanl or Electric Lifting Operation Opitons

>> Private label wholesale mens shaving razor 5 blades 3 blades

>> 300W 400W 500W Aluminum Street Pole Light IP65 Waterproof Outdoor Integrated Solar Street Lamp All in One Solar Street Light

>> 15 Tons Waste Plastic to Oil Convert Waste Plastic Tire to Fuel Oil Pyrolysis Plant

>> PP non woven white lab coat disposable ppe disposable lab coat uniform safety clothing

>> 1L Universal Snow Foam Gun Washer Car Foam Cannon Bottle for Pressure Washer Gun Soap Lance Spray

>> Hot Sale Model: ZB04-2 Double Stage Pneumatic Driven Refrigerant Recovery Pump for R22, R134, R407c, R410A

>> High Quality Save Space China Manufacture Flat Cleaning Floor Mop

>> 1000kN Microcomputer Screen Display Hydraulic Universal Testing Machine

>> UHMWPE Fiber Ultra High Molecular Weight Polyethylene Filament

>> Mx204 - Juniper Router, Mx Series Base Product Bundles

>> Fully Automatic Mobile Lifting Platform Electric Lift Table 10m Elevator Scissor Lift Tables

>> YY Home US Standard High Quality Aluminium Casement Window

>> Natural Cotton Medical Absorbent Sterilized Non-Woven Sponges

>> New Design 2022 winter Side zipper Long line blank pullover hoodies for men Sweatshirts with your own logo long sleeves

>> 4: 3 Indoor Outdoor Waterproof Digital Advertising Rental Stage Meeting Room Wall LED Video Panel Billboard Screen Display TV

>> ABS Rechargeable Solar Powered Camping Lantern Outdoor Solar Zoom Camping Tent Light LED Solar Flashlight

>> 4u Potato Peanut Harvest Machine for Sale

>> Original Mi Band 6 Mi Band 7 Smart Wristband Color AMOLED Screen Tracker Heart Rate

>> Forging Iron Anodized Bicycle Accessories

>> Fiber Laser Pipe Cutting Machine 2000W Metal Tube 6m CNC laser Cutter Machine 6000*220mm Low Cost 2kw

>> Es Top Deep Hole Drilling Machine Dh-V2220 Horizontal CNC Deep Hole Drilling