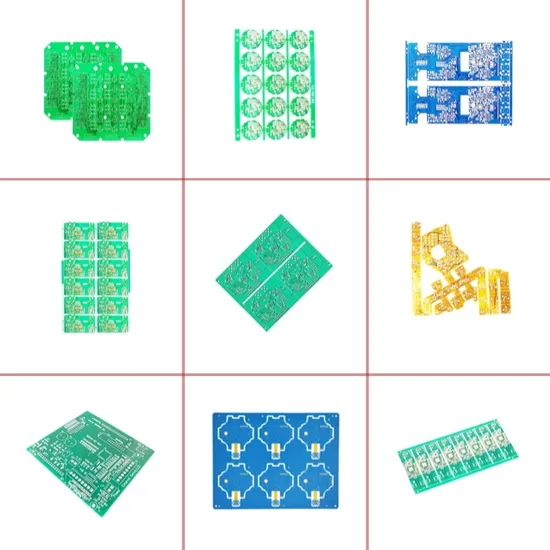

Custom Wholesale High Thin Length Width Multi Layer Rigid Flexible Copper-Impregnated Goldfinger Aluminium Ceramic Circuit Board 1-24 Layer PCB Manufacturer

Basic Info.

Model NO.

1-24 layers PBC

Material

Paper Phenolic Copper Foil Substrate

Application

Aerospace

Flame Retardant Properties

V0

Mechanical Rigid

Rigid

Processing Technology

Delay Pressure Foil

Base Material

Aluminum

Insulation Materials

Organic Resin

Brand

CL

Certification

ISO9001, 14001, 13485, 45001, 50001-IATF16949-CQC

Layer

24L

Service

OEM/ODM, EMS

Support

Fast Proofing

MOQ

A Slice

Ten Years

Export Trade Experience

Sales Model

Factory Direct

Quality Standard

Ipc-a-610 Class II & III, Ipc-a-620 Class II & III

Surface Finish

HASL, Enig, OSP, Gold Finger

Support One-Stop Service

PCB Manufacturing, Component Sourcing, SMT Placeme

Surface Finishing

HASL, Immersion Gold, OSP

Application Field

LED, Medical, Industrial, Control Board

Export Trade

More Than 10 Years

Lndustry Experience

Over 30 Years

Business Team Services

7*24 Hours Online

Transport Package

Vacuum

Specification

Custom

Trademark

CL

Origin

Shenzhen

HS Code

8534001000

Production Capacity

5000000square Meter/Year

Packaging & Delivery

Package Size

35.00cm * 30.00cm * 19.00cm

Package Gross Weight

1.000kg

Product Description

| Home | Products | About Us | Solutions | Discover | Contact Us |

| Communication equipment PCB Board | Electronic products PCB Board | ||||

| Industrial control PCB Board | Automotive PCB Board | Aerospace PCB Board | |||

| Single-Sided PcB Board | Double-Sided PCB Board | PCB 4-Layer Board | |||

| PCB 6-Layer Board | PCB 8-Layer Board | PCB 10-Layer Board | |||

| Multi-Layer PCB Board Maximum 24L | Copper PCB Board | Ceramic PCB Board | |||

| Rigid-Flex PCB Board | Rigid PCB Board | Flexible PCB Board | |||

PCB High Frequency HighSpeed Board | Aluminum PCB Board | PCBA SMT | |||

01. Technical ability - Hard board

| Design Features | 2024 | Special process design |

| Number of floors (maximum) | 24L | 1.Embedding copper ingot 2.Grading goldfinger 3.High frequency high speed material mixed pressing 4.Control deep drilling and back drilling |

| Maximum plate thickness | 6.0mm | |

| Minimum plate thickness | 0.25mm | |

| Inner layer copper thickness | 1/3~4oz | |

| Outer copper thickness | 1/3 ~6oz | |

| Minimum Through Hole | 0.15mm | |

| Min. blind hole (laser drilled) | 0.05mm | |

| Minimum buried holes | 0.1mm | |

| Through-hole plating aspect ratio capability | 16:1 | |

| Plated filled hole aspect ratio capability | 1:1 | |

| Minimum line width/spacing of inner layer | 50/50μm | |

| Minimum line width/line spacing for outer layer | 50/50μm | |

| Minimum BGA PAD | 0.2mm | |

| Minimum BGA pitch (centre) | 0.40mm | |

| Impedance control accuracy | ±10% | |

| Plated hole filling Dimple≤ | 10um | |

| Maximum Patchwork Size (Mass Production) | 610mm*720mm | |

| Surface Finish | Immersion Gold / Immersion Tin / Immersion Silver / Gold Plating / Lead Free Tin Spraying / OSP / Immersion Gold + OSP | |

| Soldermask Colour | Solder resist silkscreen: green, matte green, red, yellow, blue, black (matte black, glossy black), white Low pressure spraying: green |

02. Technical competence - Material application

| Material class | Key parameter | Material type Brand supplier Panasonic/Rogers/Shengyi/Guoneng/Ruilong/Zhongying/Lianmao/Taiguang/South Asia/Ultrasound/Taiyao |

| PTFE Series | - | R03003 AD300C Taconic RF30-7H RF-35 SG3300/GF300/GF255/SG7350D/SG7350D2 /mmWave77 GNC3304/GN300BP ZYF300CA ZYF220D RA300 RNP280 RP220 |

| PPO Series | - | AeroWave300/mmWaveG |

| Hydrocarbon Series | - | RO4730 RO4003C RO4350 RO4534 RO4535 ZYC8300 RT350B LNB33 /LNB33C/ S7136H /S7136D IT998/E EM892K/K2 |

| Extremely low loss | DF<0.002 | (M8N)R-5795N TU943N/R Synamic9GN/GN2 |

| Ultra Low Loss | 0.004≤ DF<0.002 | (M7N)R-5785N/GN Synamic8GN /Synamic8G /Synamic6N EM890K EM891K TU933+ TU883ASP IT988GSE |

| Ver y Low Loss | 0.006≤DF<0.004 | (M6)R-5775/G/N Synamic6/GX IT968/G /SE IT988G EM528/K EM890 EM891 TU883/C/A TU885 |

| Low loss | 0.009≤DF<0.006 | (M4)R-5725/S S7439 S7439G S7439C SDI06K IT150DA IT170GRA2 IT958G EM526 EM888/S EM888K TU872LK TU872SLK TU863+ TU872SLKSP |

| Mid loss | 0.018≤DF< 0.009 | (M2)R-1577 EM828G EM370(D) EM390 TU862HF TU865 S7040G S7045G SML02G(X) IT150GS IT170GRA1 IT170GT |

| FR4 | CAF | S1150G S1000H Autolad1 S1000-2M Autolad2G Autolad3 Autolad1G Autolad3G IT150G IT158 IT180A IT180I NP155F NP175F NPG151 GW1500 GW1700-1 GW2000-1 GW3000A |

03. Technical ability - soft and hard board

| Design Features | 2024 | 2024 |

| Material specification | FCCL 12-50um (Electrolysis/calendering) | - |

| Covering film 12-50um (Yellow/Black) | - | |

| Low-flow glue PP 40-100um | - | |

| RF layer number | Number of floors | 10L |

| Total plate thickness | Thickness | 0.25-2.0mm |

| Copper thickness | Inner & Outer layers | 1/4-2OZ |

| Surface treatment | Processing mode | - |

| Line width/line distance (minimum) | Face copper thickness =36 | 70/70μm |

| Aperture /Pad(min) | Mechanical drilling PTH | 100μm/300μm |

| Laser drilling Via | 50μm/200um | |

| impedance | Impedance specification | 10% |

| Solder resist | Alignment tolerance (CCD/DI) | 50um/20um |

| Soft and hard board interface area | Overflow specification | 0.5mm |

| Steel sheet/reinforcement | Fitting tolerance | 150um |

| W/B zone | Flatness (front/back) | 20um/30um |

| Appearance | Forming tolerance | 150um |

A: We are manufacturer with a separated factory.

Q2.What do I need to offer for production?

A: Basiclly PCB Gerber file and BOM list, if you have other requirement,just let us know.

Q3.MOQ?

A: There is no MOQ. We are able to handle Small as well as large volume production with flexibility.

Q4.What is needed for quotation?

A: PCB : Quantity, Gerber file and Technic requirements(material, surface finish treatment, copper thickness, board thickness )

PCBA: PCB information, BOM, (Testing documents)

Q5.What file formats do you accept for production?

A: Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

Q6.Are my files safe?

A: Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process.

All documents from customers are never shared with any third parties.

Q7.Shipping cost?

A: The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us

to quote you the shipping cost.

Q8.Do you accept process materials supplied by clients?

A : Yes, we can provide component source, and we also accept component from client.

Q9.Your production delivery date?

A : After confirming the product, we will confirm and inform the customer of the accurate production schedule and delivery time. We will make every effort to ensure that the product is delivered within the specified time, so we will arrange the production line by the independent foreign trade team of the factory.

Q10.Product qualification rate?

A : Our product pass rate is generally up to more than 99%, export business we should pay more attention to quality, so as not to cause economic losses on both sides, so we will ensure that the factory independent professional export business quality team for quality inspection.

Q11.Export services?

A : The factory has set up a dedicated export service business team and quality inspection team, this team does not participate in the business docking in China, so it can provide more comprehensive services and guarantees for trade customers.

Company Profile

Annual statistical sales ratio

Cooperative Clients

>> Lathe Machine Torno Big Bore Horizontal Lathe Machine (CS6250B) Torno

>> Gmf2015b Low Cost 5 Axis Vertical CNC Gantry Type Drilling Milling Machine with Price

>> Automatic Clamping Wireless Charger for Car

>> Automatic Drain Valve for Spray Gun at 0.2 Bar to 0.4 Bar

>> aluminum perforated interior decorative metal wall panel

>> Cheap New Product Fashion 4 Wheeler ATV for Kids Adults ATV Hot Selling Wholesale

>> High Quality Promotional Steel Metal L Shaped Support Shelf Brackets

>> Vintage Retro Snow Gray Style 304 Stainless Steel Matt Round Dinner Dessert Serving Dishes Plate

>> Factory Supply Cute Mini Reiner Braun Attack on Titan Wholesale Japanese Anime Action Figure Toy

>> 5SHY4045L0001 3BHB018162R0001 ABB CONTROLLER IGCT MODULE BRANDNEW

>> OEM 54650-4h650 Car Suspension Kyb Shock Absorbers for Hyundai Satellite 1997

>> Chinese Factory Cordless Impact Li-ion Battery Electric Wrench

>> Concrete Test Hammer Calibration Steel Anvil

>> 1500W 2000W 3000W 6000W Laser Cutter Pipe / Tube CNC Metal Fiber Laser Cutting Machine 1.5kw 2 Kw 3kw 6kw

>> Solid Quality Black Aluminum Foil Plastic Transparent Glass Shutter Window And Door

>> Meibao High Pressure Pump Equipment Machine for Washing Detergent Powder Production Line Plant

>> Poly-Cotton Thread Knitted Winter Latex Palm Coated Safety Gloves

>> Factory price ett polymer materials medical endotracheal tube holder

>> High Quality Outdoor Tactical Portable Pliers Multi Tool Combination Camping Folding Multitool Pliers

>> The Hottest Design Graceful Modern Home Furniture Living Room Solid Wood Sofa

>> Film Free Shrink Tester Shrinkage of heat shrink film Testing Machine

>> Multimeter VC9805 Test Inductance Capacitor LCD Instrument Multi-Function Instrument

>> Desktop PC LCD LED Monitor Computer 15/17/21.5/23.8 Inch Display Wholesale Custom-Made

>> Heavy Duty High Precision CNC Lathe Machine Ck61125e with 10ton Loading Capacity

>> High Power Long Distance Waterproof Outdoor Binoculars

>> Sephcare edible color E153 vegetable carbon black food color powder pigment

>> Own Brand Shaving Brush with Bowl and Safety Razor Set

>> Paint Production Line Automatic Wall Paint Production Line High Efficiency Water Based Paint Production Line

>> Small Metal Drill Vertical Stand Drilling Machine Z5032 Auto Feed Vertical Drilling Machine

>> 5gallon Bottle Blower Machine Barrel Making