Innovative Design Features for Custom High-Performance LPG Cylinder Production

| US$50,000.00-200,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

LISHENZW-001A

Function

Storage Pressure Vessel, Separation Pressure Vessel, Heat Pressure Vessel, Reaction Pressure Vessel

Application

Liquefied Gas

Material

Stainless Steel

Pressure

1.6MPa≤p<10.0MPa

Storage Medium

Moncombustible/Nontoxic

Pressure Level

Medium Pressure (1.6MPa≤p<10.0MPa)

Condition

New

Volume (M³)

Customized

Key Selling Points

Easy to Operate

Design Pressure(MPa)

Customized

Core Components

PLC, Engine, Bearing, Gearbox

Place of Origin

Tai′an, Shandong

Max Working Pressure(MPa)

Customized

Design Standard

Customized

Product Name

LPG Production Line

Outer Material

Steel

Dimension(L*W*H)

Customized

Inner Material

Steel

Transport Package

Plastic Net

Specification

Customizable

Trademark

TAIAN TITAN

Origin

Tai′an, Shandong

Production Capacity

30 Sets/Month

Product Description

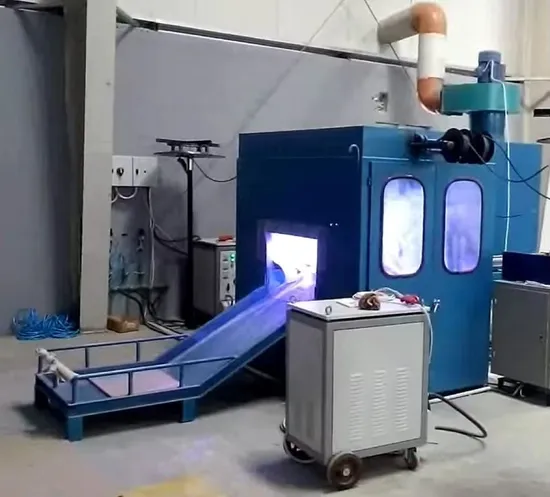

Product DescriptionHigh-Efficiency Production: Step into the future of industrial prowess with Tai'an Lishen Machinery Technology Co., Ltd's cutting-edge gas cylinder production line. This marvel of modern engineering offers unparalleled high-output efficiency, capable of producing an impressive [X] gas cylinders every hour. Elevate your production capabilities with this essential solution designed to meet the ever-growing demands of the dynamic gas cylinder manufacturing industry.Advanced Technology: Propel your production standards into a new era with our groundbreaking technologies. The hallmark of our production line is its engineering brilliance, featuring state-of-the-art innovations like automatic argon arc welding. This advancement ensures airtight and robust cylinders, virtually eliminating gas leakage risks. Precision Manufacturing: Our line, equipped with high-precision machinery and cutting-edge automation, achieves remarkable dimensional accuracy of up to ±[X]mm. This precision fosters standardization and seamless interchangeability, revolutionizing inventory management and elevating your after-sales service.

1. Sheet Metal Processing: Begin your journey to excellence with top-tier steel sheet metal. Our process leverages advanced laser technology for precise sizing, complemented by an extensive array of forming equipment to craft the resilient cylinder body. This crucial step lays the foundation for producing cylinders that meet the highest standards of quality.

2. Welding Process: After formation, our sophisticated automatic welding system takes over, executing longitudinal and circumferential welds that go beyond international standards. Rigorous non-destructive testing, including ultrasonic and X-ray inspections, ensures weld integrity, promising unrivaled safety and reliability for each cylinder produced.

3. Surface Treatment: Enhance the durability and visual appeal of your gas cylinders with our comprehensive surface treatment process. Each phase, from sandblasting and rust removal to priming and finish painting, is meticulously executed to boost corrosion resistance. The result is a product lifespan that exceeds expectations, maintaining a pristine appearance throughout its service.

Product Parameters

| Material | Stainless Steel ; Gavalized Steel | Compressed Air Pressure | 0.45MPa |

| Production Line | Non Pressure Water Tank &Pressure Water Tank | Transmission Type | Flexible |

| Certification | CE | Rhythm | Flow Production Line |

| Transport Package | Container | Rated Voltage | 380VAC 50Hz |

Company Profile

Certifications

FAQ

>> Living Room Furniture Melamine Book Shelf Bookcase

>> Skmei wholesale simple design stainless steel nylon strap hand clock women custom logo ladies quartz watch

>> Christmas Space Valentine Gift OEM Custom Logo Tableware Storage Rack Pot Lid Holder Plastic Spoon Rest with Drip Pad

>> Customized 300W 2000W Pulse Laser Cleaner Washing Wheel Cleaning Machine Car Polishing

>> Factory Customized Unique High Quality Pear Glaze Ceramic Taper Candle Stick Holder for Home Decor

>> Die Casting Aluminum Auto Parts Aluminum Auto Machinery Parts Die Casting

>> European style 3 tier floating wedding wooden bamboo decorative cup dessert bakery cake plate display stands set

>> Meidi New Energy Electric Four-Wheeler Adult Travel Disabled Scooter Car

>> New Product 4K 1X2 2X2 1X4 4X1 Support Audio HDMI Matrix Video Wall Processor

>> IEC 61238-1 Cal Bimetal Cable Al. Cu. Lugs in Manufacturers Hex Crimping

>> Taijia electromagnetic flow meter flowmeter flow meter electromagnetic remote for Chemical industry

>> China supplier hvac steel gypsum aluminum ceiling access door with drywall

>> Yellow Inflatable Dog Slide (AQ808)

>> 4 Feet Glue Spreader Machine Made in China

>> Ultrafine/Universal/Coarse/Fine/Superfine/Grinding/Crushing/Milling Grinder Machine of Food, Flavoring, Pepper, Salt, Sugar

>> EV Extral Fast Charging Piles DC-DC High Power Interleaved LLC Topologies Fast Recovery Diode Frd Osg60r030hzf To247 Power Mosfet

>> Customized Multi-Functional Drilling & Tapping Machine 32mm (ZS4032)

>> Shengfeng 20kHz 2000W Ultrasonic Welding Plastic Machine high frequency welder

>> Self Loading Small Mobile Concrete Mixer Machine

>> Home Use Toothbrush Place Rack Toothbrush Holder Wall Mounted with UV Sterilizing UV LED Sterilizer

>> Industrial Butter Aeration Mixer High-Performance System for Bakery & Confectionery

>> Insulated food delivery bag motorcycle to keep food cold

>> Hardware Encryption 256 Zinc Alloy 128GB32GB 64GB Pen Drive AES256 Hardware Encryption Flash Memory Stick USB 3.0 Flash Drive

>> Clear Louvre Glass with Pencil Round Edge Work

>> OEM Factory Sale Professional Ink Alternative for Kk Inkjet Printers Bljinks-K1

>> 4wsp19-56-300-2200-a/D Solar Pump with Plastic Impeller

>> Monthly Deals Tinplate High Speed Rotary Shear Cut to Length Line Machine

>> Cheap Ck6136A Torno CNC Hot Sale Mazak CNC Lathe Price with Automatic Turret

>> Garment Elastic Tape Elastic Cord Rubber Inside

>> Natural White Marble Stone Waterjet Art Patterns Mosaic