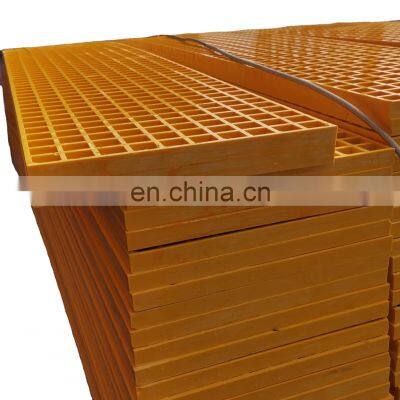

Fiber reinforced plastic grating manufactures fiberglass frp floor grating

Product Description

Product DescriptionProduct DescriptionFiber reinforced plastic grating manufactures fiberglass frp floor gratingFiber reinforced plastic grating manufactures fiberglass frp floor grating is used in variety of applications including docks, piers, boat lifts and decks in 4’ x 12’ panel sizes(3/4” square mesh opening on top surface). It is also used in and around pools, marinas, waterparks and other public recreationalareas. Micro-Mesh has maximum UV resistance, has a comfortable surface for bare feet and is durable, with a high strength to weight ratio. Depth options include 1/2”, 1” and 1-1/2”. Micro-Mesh panels are the right choice to minimize vibration from rolling cart or wheelchair traffic. The panels with a 1/2" open area between bearing bars are ADA compliant and meet the "15 mm ball test." Micro-Mesh FRP access flooring system is designed as a low cost alternative where subfloor access and unobstructed air flow is required. Lightweight 2'x 2' Micro-Mesh panels are easily removed, providing ready access to electrical conduits, air supply plenums, and service lines.We can produce many colorsFiber reinforced plastic grating manufactures fiberglass frp floor grating, such as yellow, green, Blue, Red ,Gray, black, white and so on, we also accpet customized color according the RAL color card number. Fiber reinforced plastic grating manufactures fiberglass frp floor grating is composed of alternating directional layers of continuous glass fiber for strength, with resin toconsolidate the fibers and provide the shape and corrosion-resistance. Molded grating has very high impact tolerance, as well asthe highest chemical resistance of any fiberglass grating. It can be made slip-resistant by adding grit to the surface.Specifications(mm)a*b(mm)weight(kg)38*38*251220*36605438*38*301220*36607038*38*381220*36601000*4007888150*50*501220*36609819*19*38*38*301075*36267238*38*651030*404014140*40*401010*40408119*19*38*38*381220*36609225*25*50*50*501220*366062Product FeaturesFiber reinforced plastic grating manufactures fiberglass frp floor gratingCorrosion resistantHas very excellent acid-proof, alkali resistance, resistance to organic solvents and salt, and many other gas and liquid medium corrosion performance, has the incomparable superiority in the field of anti-corrosion.According to the requirements of the actual use, it is economical to choose the base material for the use of phthalic, polystyrene, and vinyl resin.Comparing with other floor materials, FRP moulded grating provides a series of benefits, unmatched impact resistance, while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install. FRP moulded grating is made of continuous fiberglass fully soaked in unsaturated polyester resin giving a uniform structure and perfect bi-directional mechanical properties.1) Corrosion and chemical resistant2) High strength ,light weight and good bearing capacity 3) Fire retardant The flame propagation rate of ordinary flame-retardant grille (ASTM E-84) does not exceed 25; the flame propagation rate of advanced flame-retardant vinyl grille does not exceed 10. The oxygen index is not less than 28 (GB 8924).4) Slip-resistant and Anti-aging the life time about more than 20 years.7) Easy maintenance product displaysProduct production processProduct applicationMini mesh Plastic flooring fiberglass reinforced FRP sheets grating is a glass fiber reinforced material, unsaturated polyester resin matrix, through a special processing composite with a lot of space, FRP grating can be used as structure Materials, corrosive environment for the floor, trench cover, platform, ship deck, stairs, plank road and so on.ConstructionGuardrails, stairs, ladders, wall gratings, platforms, etc.Drainage treatmentDrainage ditch, drain grating, platform, structure, etc.Civil EngineeringFloors, sidewalks, bridges, tree protection, car washes, parking lots,Protect grating, etc.Chemical IndustryWork platform etc.Food processing and aquacultureThe platform, engineering guardrail, etc.Ocean industryPlatforms, fencing, sidewalks, etc.Process &PackingPacking Details : Packing, pallet,wooden box,or as the order....Delivery Details : 15-30 days after deposit for frp gratingHello friend, if you need please contact

>> Heavy Duty Recovery Winch 20000lbs for Trucks with Steel Wire Rope

>> 2021 New Virtual Reality Motorcycle Ride 9d Vr Motorcycle Racing Simulator with CE RoHS

>> flat web cargo lifting net

>> Cosmetic Packaging Round Glass Bottle Aluminium Caps Dropper for Rose Essential Oil Bottle

>> Luxury Europe front safety door design cast aluminum doors entrance

>> Modern Luxury Home Furniture Lounge Living Room Relaxing Genuine Leather Leisure Chair

>> Economic CNC Gear 4-Axis Hobbing Machine Max Dia 280mm Workpiece, 1-3 Module Range

>> Xingpai Brand Multi-Layer Three Layer Co-Extrusion LDPE HDPE PE Film Blowing Machine Plastic Extruder Biodegradable Plastic Blown Film Extrusion Machine

>> AAA Quality 100% Garanty Top Selling Mobile/Cell Phone LCD for Samsung Note 20/Note 10/Note 9/Note 8/S22/S22 Plus/S22 Ultra/S21/S10/S10 Plus/S9/S9 Plus/S8 G950

>> All Tag Security 58kHz EAS Am Tag

>> Ssuv-A01 6W 8W 14W Stainless Steel 304/316 System UV Sterilizer for Koi Tank Pool Disfection

>> Photovoltaic Series Fuse &Fuse Base

>> Hy-12m High Speed Draw Texturing Machine of 240 Spindles for Polyamide

>> Custom Aluminum Stainless Steel Lampshade Car Sheet Metal Stamping Deep Drawing Parts

>> Taijia Electric concrete resistivity tester potential detector for sale

>> 400~1200kg Electric Glass Vacuum Suction Cup

>> Customized Logo Wall Power Socket 15A American Wall Electric Socket

>> China Manufacturer Filling and Canning Machine for Can Beer

>> Hot Sale Garden Tools Glass Trimmer Backpack Gasoline Engine Grass Weeder

>> Long Arm 760mm Single Needle Compound Feed Leather Sewing Machine

>> 4HP Ohv 4-Stroke Gasoline Agricultural Cultivator Mini Tiller with 36cm Working Width

>> Customizable size biodegradable disposable wooden plate compostable dinner plate

>> Solar LED Safety Warning Barricade Light

>> Acoolda Large Waterproof Thermal Custom Insulated Food Delivery Bag

>> Good Quality Original Blood analyzer machine Mindray BC-20 Auto Hematology analyzer with a best price

>> High-Efficiency SKJ System Wood Pellet Production Equipment for Sale

>> Gas Cooker Spark Plug/Oven Parts/Ceramic Ignition/Oven Spark Plug/Gas Stove Igniter

>> Dl Precast Concrete Shape Molds

>> Sugarcane Bagasse Bento Lunch Boxes 6inch Burger Box Bagasse Pulp Sugarcane Bagasse Paper Lunchbox

>> Nice Quality Evaporative Cooling Pad Manufacturing Line Cooling Pad Production Machine