Waxing Device Oiling Deviceused in Warping Machine

| US$2,500.00-4,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

WTGA628

Computerized

Computerized

Precision

High Precision

Certification

CE, ISO9001: 2000

Warranty

1 Year

Customized

Customized

Condition

New

After-sales Service

1 Year Guarantee Period

Transport Package

Pallet

Specification

190~360cm

Trademark

WT

Origin

China

HS Code

8445901000

Production Capacity

1000sets/Year

Product Description

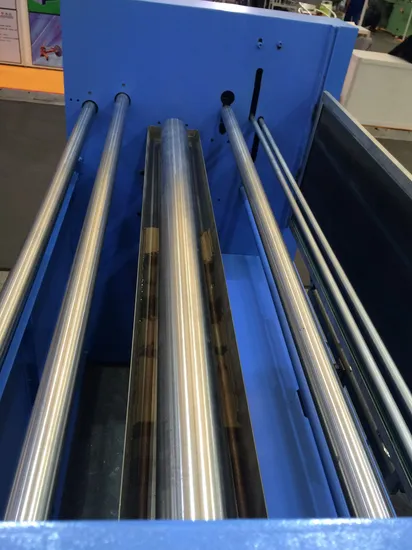

Product DescriptionWaxing device working principle is that waxing roller along the direction of the yarn flake on the sizing machine body, is a yarn pressure roll. The yarn flake hold point on the yarn pressing roller is lower than the yarn flake hold point on the waxing roller. The utility model enables stable contact surface between the yarn flake and the waxing roller, ensuring uniform yarn-waxing and improving waxing quality of the yarn flake. Detailed Photos

Machine features

High speed sectional warping machine is designed for flexible production arrangement and high quality weaving requirement. It's preparatory to weaving lines of worsted wool textile, natural silk fabric, filament fabric, special screen cloth, yarn dyed fabric, towel fabric and other special fabrics, can be completed with rapier, gripper, water-jet, air-jet and shuttle-less looms with years' of textile experiences and the latest mechanical and electric technologies.

Main Technical Specification

1. The machine is with high-strength steel structure frame, which make the machine more stable, easier for installation and can prolong the service life.

2. The big round roller is also made from high-strength steel which broke the traditional wood frame roller. The big steel roller is more suitable for large yarn package and can highly increase the warping tension.

3. The product is equipped with advanced electrical control system. The speed control motor is the main power of warping and down-shaft. Also it's equipped with reliable and sensitive brake rigging, which make the warping more convenient.

Machine installation and commissioning

This machine was semi-finished before delivery, please assemble all the parts together before starting work. To ensure the stability of the machine, please install all the foot screws and do the horizontal correction for every direction when install the machine. The acceptance tolerance value of horizontal correction is ±0.1mm/100mm

Product Parameters

| Specifications of sectional warping machine | ||

| Warping and Beaming machine | ||

| 1 | Work width | 1900~3200mm |

| 2 | Beam diameter | 600mm,800mm |

| 3 | Warping Speed | 400m/min can be adjusted step-less |

| 4 | Beaming speed | 100m/min can be adjusted step-less |

| 5 | Creel speed | 0.467~2.29mm/drum 18 grades adjustable |

| 6 | Stub Axle Height | 30~200 adjustable |

| 7 | power | Warping 3KW Beaming:7.5KW |

| 8 | Load/drop beam | automatic air press, load/drop beam device |

| 9 | Warping Machine Frame | welded steel bar |

| 10 | Drum | Steel |

| 11 | LED Display | Eview colorful touch screen |

| Pneumatic reed | ||

| 1 | Frame | welded steel bar |

| 2 | Reed | special stainless steel reed |

| 3 | Splitter plate | alumina ceramics |

| Creel | ||

| 1 | Type | rotary, H Type |

| 2 | Pitch | Customized |

| 3 | Layer | 8 |

| 4 | automatic stop device | infrared automatic stop |

| 5 | spindles | 600 |

| 6 | Tension device | Ring type |

Packaging & Shipping

PACKAGING PICS:

Company Profile

WHO ARE WE?

Liaocheng Wetex Import & Export Co., Ltd, with over 20 years of experience, specializes in fully automatic warping and high-speed weaving machinery. We have our own factory, a research and development center, and partnerships with leading domestic manufacturers. Our high-quality products are recognized in over 20 countries across Asia, Europe, the Americas, Oceania, and Africa. Known for competitive pricing and precision, Wetex provides comprehensive solutions, including on-site installation and support in various languages. We are dedicated to innovation and customer satisfaction, making us a trusted name in the textile machinery industry.

Our Advantages

WHY US?

01 Industry experience

With rich experience in the industry, Wetex gives professional guidance and advice according to the needs of customers.

02 Customer Oriented

Wetex always puts customer's satisfaction as the first place, from professional sale suggestion, order tracking, to after sale one-site service, offering customer a life-cycle support.

03 Long-term cooperation

Wetex offer long warranty period, flexible payment methods, online and offline exclusive services, etc. are all to ensure long-term and stable cooperation

04 Own factory endorsement

OUR TEAM:

EXHIBITIONS WE ATTEND:

After Sales Service

SERVICES WE OFFER:

FAQ

1.Q:What are your payment terms?

A:L/C,D/A,D/P,T/T,Western Union,MoneyGram

2.Q:What is your logistics method?

A:Express,sea,lan,air

3.Q:How long is your lead time?

A:30-90 Days

4.Q:How about your after-sales service?

A:We offer engineers available to service overseas under merchandiser's supervision and translation

5.Q:Can i go to the factory for a field trip?

A:Welcome to our old and new friends to visit our factory very much,In addition,if you wish we will send you our instructions and relevant information to facilitate a face-to-face meeting 6.Q:Are you a manufacturer or trading company?

A:We are the leading manufacturer of high speed rapier loom and fully automatic sectional warping machine. And also with many years business relationship with Local textile machinery accessories factories, we also have a trading company to supply one stop solution for our foreigh customers

Wetex is not only a trading company but owned self factory to gurantee the quality, delivery time and price effeciency

>> Poultry Pellet Feed Machine Production Line for Animal Feeds

>> New Feather Cotton Ball Fiber Pillow Stuffing Filling Machine Carding Machine Pillow Filling Making Machine Price

>> Hongyuan Portable ATV Winch 4500lb 2ton Capacity Fast Speed with Wired Remote

>> Double Colour Series Plastic Injection Machine

>> 3000L 30hl Stainless Steel Double Wall Glycol Jacketed Cooling Fermentation Tank

>> Excavator Crushing and Screening Bucket, Construction Waste Crushing and Screening Bucket

>> P3/P4/P5/P6/P8/P10 Outdoor Front Service LED Panel

>> China Factory Hover Kart Go Kart/ Hovercart

>> PP/PVC Plastic Corrugated Pipe Production Line for Drainage/Sewege/Cable Duct/Electric Conduit

>> Bestchickencage Ventilation Control System China Environmental Ventilation Control System Manufacturer High-Quality Chicken House Naturally Ventilated Systems

>> 3 Axis Full Automatic Hydraulic Metal Surface Grinding Machine Sg2550ahd Surface Grinding Machines for Sale

>> Old Brand Italy Savio Orion Used Auto Coner 60 Spindles Q2 690 Hollow Spindle -5 Panel in Hot Selling

>> Factory Price Rock Crushing Jaw Stone Crusher Machine

>> YY designed modern Australia brand fixed awning aluminum window for home or apartment use

>> Ywt Series 600t CNC Press Brake with 12mm Thickness 20FT Width

>> Ricoh Logo It Gift Novelty Gift Multi-Functional Screen Wipe

>> PVC Slipper and Sandal Making Machine

>> Electrical Cabinet Machine Press Brake

>> Large Hollow Spindle Bore 4 Round & 4 Square Tool Holders CNC Lathe Internal Turning CNC Machining Lathe

>> Guaranteed Quality Fish Feed Machine Extruder Screw Extruder Fish Feed Extruder Fish Feed Machine Extruder Fish Feed Sinking

>> HC-I030 Medical equitment High-Frequency Electrosurgical Generator surgical,Electric knife surgery,Electrosurgical unit

>> Dx68 P32 Sp52 Excavator Forklift Truck Oil Hydraulic Hose Crimper Tubing 2"6-51mm Automatichydraulic Crimping Machine Pipe Crimper Manual Crimping Tool

>> Portable 12V Mini High Power Under Seat Car Subwoofer Active Car Audio Slim 8 Inch Subwoofer

>> Arched glass double door design for home luxury front house exterior iron works black entrance doors

>> Steel Plates Gantry Type CNC Drilling Machine

>> Isb800an-3 One Step Pet Bottle Injection Blow Machine Pet Bottle Blowing Machine

>> Automatic Fish meat picker

>> Automatic Grinding Equipment Machine After Welding of Electric Cabinet Panel

>> 2022 Customized Sublimation Singlet of Pommel Pattern

>> Swing Arm Cutting Machine for Leather_Textile_Fabric Hydraulic Swing Arm Die Press Clicker of Hydraulic Clicking Press Die