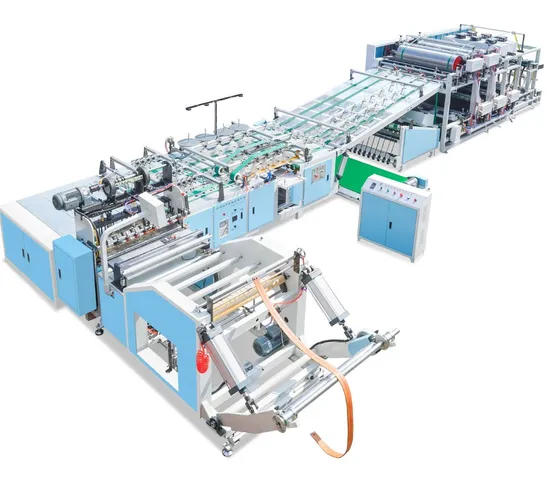

Double Sides Printing Plastic PP Woven Bag Cutting Sewing Machine

Basic Info.

Model NO.

YX-QFY800-II

Product Line

1

Lines

1

Voltage

380V

Seals Mode

Trilateral Seals

Speed

High

Continuous-Rolled

Yes

Sealing & Cutting

Heat-Sealing Heat-Cutting

Machine Type

Bag Forming Machine

Computerized

Computerized

Type

Plastic Bag Making Machine

Printing Colors

Customized

Double Sides Printing

Yes

Hot or Cold Cutting

Customized

Cutting Width

200-800mm

Total Power

7kw

Transport Package

Container

Specification

1180*4700*1900mm

Trademark

yongxu

Origin

China

Production Capacity

32-65PCS/Min

Packaging & Delivery

Package Size

118.00cm * 470.00cm * 690.00cm

Package Gross Weight

6000.000kg

Product Description

Application Suitable for cutting and sewing all kinds of market bags, fertilizer bags, rice bags, and express paper and plastic bags, it is a one-time processing equipment to complete the whole roll of woven bags to finished products.

The machine integrates cutting and automatic edge folding (paper wrapping), automatic sewing, printing and automatic material collection into one machine. With the characteristics of fast speed, easy operation and convenient maintenance, it is the ideal equipment pursued by all kinds of market bags and fertilizer bags manufacturers.

1.PLC control : Easy touchscreen to switch hot/ cold cutting function.

2.It can work for making bags with/ without printing by your choice.

3.Easy operation: One worker can coverall the jobs to this machine.

4.Suitable for most bags , Normal PP woven bag, laminated bags, paper-plastic compound bags etc. if any questions for it, customers can provide sample bags to check before confirm order.

Product Description

| Model | YX-QFY800-II |

| Max.roll diameter | 1200mm |

| Fabric width | 200-800mm |

| Fabric cutting length | 400-1300mm |

| Production capacity | 32-65Pcs/min |

| Colors printing logo | 2-4 colors |

| Hot cutting knife | Yes |

| Heat power | 2.8kw |

| The air consumption | 0.36M/Minute |

| 90 Degree Transfer tweezer | |

| Type | Gripper type |

| Feeding motor | 2HP*2Pcs |

| Distance Between stitches | 7-13mm |

| Fold sewing guide device | Single fold |

| Folding Width | 20-30mm |

| Language | English |

| Mark Reading Sensor(for pre-printed roll) | yes |

| Power consumption | 7kw |

| Machine dimentions | 1180*4700*1900mm |

| Machine weight | 6000KGS |

* The data depends on processing specification and the physical property of material.** Specification and dimensions are subject to change without prior notice.*** Special specification and versions on request.

Pingyang Yongxu Packaging CO.,LTD, Founded in 2010 at Xiaojiang Town, Wenzhou City, Zhejiang Province, China,

We are professional for complete line of PP Woven bag making machines such as Cement Woven Bag Making Machine, ,Rice Woven Bag

Making Machine, fertilizer Woven Bag Making Machine, Grain Woven Bag Making Machine, corn Woven Bag Making Machine, soybean Woven bag making machines, sesame Woven Bag Making Machine, Jumbo Woven Bag Making Machine, FIBC Woven Bag Making Machine, and Mesh Bag Making Machine, Leno Bag Making Machine, Plastic Rope Making Machine as well.We also make PP Woven bag Production Line such as Cement Woven Bag Production Line, Rice Woven Bag Production Line,

fertilizer Woven Bag Production Line, Grain Woven Bag Production Line, corn Woven Bag Production Line, soybean Woven bag Production Line,

sesame Woven Bag Production Line, Jumbo Woven Bag Production Line, FIBC Woven Bag Production Line, and Mesh Bag Production Line,

Leno Bag Production Line, Plastic Rope Production Line.

It is a specialized manufacturer of series of whole set plastic machinery products such as Complete Line of Woven Bag Making Machines, PP Mesh/Leno Bag/FIBC Woven Bag/Container Bag/Cement Bag/Rice Bag Making Machine,Plastic Bag Making Machine, Plastic Rope Making Machine. Having passed ISO9001:2000 International Quality System

authentification and got CE Certificate. Details Images

How to make pp woven sack

Certifications

Work shop

Shipping &Customer visiting

>> China Linen Cotton Fabric Manufacturer Customized Home Textile Digital Print Linen Cotton Viscose Fabric for Garment Household

>> Deep Throat Depth CNC Hydraulic Press Brake

>> Low Price Chinese Sinotruk New HOWO 6cbm 4X2 Light Truck Garbage Truck for Sale

>> Tilt in Spece Mobility Kid Chair for Old People Electric Rise Recliner Massage

>> Discount Cowtotal Factory Universal Auto Car Electric Fuel Pump for Toyota Corolla Noah Innova Hyundai Nissan Mitsubishi Pajero Chevrolet Mazda3 Suzuki

>> JIMBO smart 20 guns metal digital storage fire resistant gun safe cabinet

>> 50 Meters Dental Floss Nylon Floss Waxed with Mint Flavor Customized

>> St-747e Direct Drive Motor Overlock Industrial Sewing Machine Textile Machine

>> High Quality Biomass Comprehensive Crusher, China Alva Woodworking Machinery, Wood Chipper

>> Office Small Automatic 2 Roller Adjustable 220mm Width Photo A4 Hot Cold Laminator Laminating Machine

>> Efficient Honeycomb Paperboard Production Line with High-Speed Laminator

>> Biedas Iepe Signal Conditioner Eleven Channels Constant Current Source Paired with Acceleration Sensor

>> Best Selling Meat Paste Peanut Butter Processing Colloid Mill Grinder

>> 150 Inch Home Alr Pet Crystal 4K Ultra Short Throw Laser Projector Fixed Frame Screen

>> Wholesale High Power 100W to 20kw off/on-Grid Wind Turbine Generator for Home

>> Factory Direct Support Custom Support Send Samples Electric Scooter Mobility E Scooter Electric Mobility Scooter

>> Infrared Warm Palace Belt Warm Palace Belt Instructions Beauty Gifts

>> Men′s Sports Water Repellent Breathable Cycling Mountainbike Shorts

>> Universal Auto Storage Organizer Car Trunk Bag Large Capacity Backseat Storage Bag Trunk Cargo Mesh Holder Pocket Black

>> China Manufacture CE Standard Car Spray Paint Booth for Sale

>> High Procession Manual Lathe Ca6280b Gap Bed Lathe Machine

>> Office Ergonomic Chair Computer Chair with Lumbar Support Gaming Chair Racing

>> 10KG Factory Direct Plastic Body Double Drum Twin Tub Washing Machine In Pakistan Price

>> Stove Electric Home Kitchen Gas Electronic (JZSE4001)

>> 300d 1000d 3000d Colored High Tenacity PP Filament Yarn

>> ZC3 Sclerometer swiss hammer test rebound test hammer hardness of concrete

>> Durable Thickened Double Shoulder Top Quality 41 Inch Guitar Music Instrument Backpack Cover Cases Bag (CY8809)

>> Ce Certificate Anka Industrial Lift

>> Tungsten Carbide Cylindrical Ball-Rolling Pins for Milling Chemical

>> Eco-Friendly Printed Writable Self Adhesive Reinforced Water Activated Kraft Paper Packing Tape