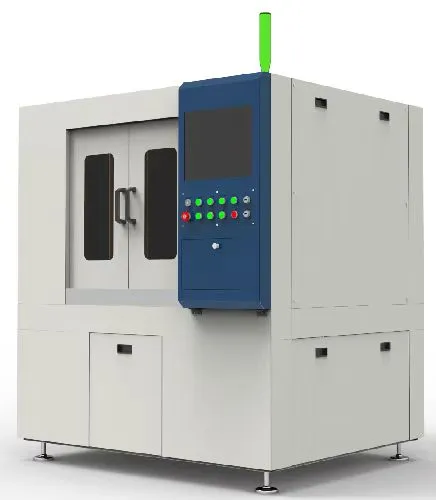

High Precision High Speed Cut CNC Metal Fiber Laser Cutting Machine for Metal Sheet Plate Engraving Gold Jewelry Aluminum Stainless Steel

| US$15,000.00-22,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

DF-M0606

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Source

Raycus*Max*Ipg

Wavelength

1080mm

Cuttable Material

Stainless Steel&Carbon Steel&Aluminum&Copper etc.

Delivery

25 Days

Cuttable Range

600*600mm

Power

1000W/1500W/2000W/3000W

Maximum Cutting Speed

60m/Min

Positioning Accuracy

0.02mm

Transport Package

Wooden Box

Specification

1800*1600*1800mm

Trademark

HND LASER

Origin

China

HS Code

8456110090

Production Capacity

1000

Packaging & Delivery

Package Size

1200.00cm * 1300.00cm * 1800.00cm

Package Gross Weight

600.000kg

Product Description

Product DescriptionFully Enclosed Shell Structure

The fully enclosed shell structure greatly improves safety.

Bus Control System

It enables data transmission via Bochu bus control system and features fast speed and stability. This system is easy to be operated and rich in functions. Even green hands can cut high-quality samples.

High-precision Cutting Head

This cutting head can achieve smoother cutting, especially suitable for situations that require high cutting quality.it has long lifespan and low maintenance cost.

Massive Production Database

* Users can invoke cutting technology from the database when cutting sheet of different materials and thickness

* Have multiple thick sheet cutting technologies like air cutting, counterboring technology, etc.

Product Parameters

Parameters of the whole machine

| Model | DF-M0606 |

| Cutting Range (mm) | 600*600mm |

| Laser Power (w) | 1000W&1500W&2000W&3000W |

| Maximum cutting speed | ≤60m/min |

| Maximum idle speed | 150m/min |

| Positioning Accuracy | 0.02mm |

| Reposition Accuracy | 0.02mm |

| Cuttable material | 1.Stainless Steel Sheets&Galvanized Sheets&Electrolytic Sheet&Silicon Sheet(0.2mm-6mm) 2.Aluminum Alloy Sheet(0.2mm-6mm) 3.Brass Sheet(0.5mm-6mm) |

Key component configuration

| Main Component | Description | Brand&Origin |

| Laser | Optional | Raycus*MAX*RECI/China |

| Optical System | Imported Medium Membrane | UK |

| Laser Cutting Head | Optional | RAYTOOLS/BOCU |

| Chiller | Laser Specific Chiller | Hanli/China |

| Reducer | Xinbao Flange Output Structure | SHIMPO/Japan |

| Motor | Servo motor | Inovance/China |

| Computer System | Yanzhong Industrial Computer | HP/Japan |

| Electrical Components | Schneider Electric | Schneider/France |

| Cutting Software | Professional 2D Laser Cutting System | HND Laser |

| Tracking Sensor System | High-Precision Automatic Sensing, Accuracy ±0.1mm | HND Laser |

| Machine Bed | Gantry Type | HND Laser |

Our customers

Certifications

Laser Cutting Machine SGS Certificated

(Can be customized to your needs)

Experience unparalleled confidence with our laser cutting machine, proudly certified by SGS. This prestigious certification assures that our equipment not only excels in mechanical performance but also adheres strictly to international safety and stability standards. For business owners, managers, and operators, this represents a critical promise of reliability and safety, ensuring seamless operation and peace of mind during every use.

Packaging & Shipping

Our laser tube cutting machines have been sold to over 50 countries worldwide, ensuring that your goods will be delivered safely and smoothly to your factory.

Company Profile

Company Information

ZHANGJAGANG HNDLASER TECHNOLOGY CO.,LTD HNDLaser Technology Co., Ltd. is a prestigious national high-tech enterprise backed by HNDLaser in Zhangjiagang. We specialize in the research, development, production, and application of cutting-edge laser equipment. Our portfolio includes Zhangjiagang HND Intelligent Equipment Co. and other esteemed enterprises.

With consistent and significant annual R&D investments, our products have gained wide market recognition, ensuring a stable production output across the entire laser industrial chain. HNDLaser is firmly rooted in the philosophy of being people-oriented and driven by scientific and technological innovation. Maintaining a focus on innovation and talent cultivation is our cornerstone for increasing market share and product recognition continually.

After Sales Service

A. Pre-Sales Service

1. Technical Consultation: We will provide you with any professional technical and pricing consultation within two hours based on your needs. We can also send relevant samples and product information, and respond quickly to any questions you may have, such as processing table size, precision, cutting thickness, and operating costs related to cutting parameters.

2. Site Visits: We welcome you to visit our company for inspections at any time and from anywhere.

B. After-Sales Service

1.We have established a comprehensive after-sales service system to track customer feedback 24/7.

2. From the date of purchase, you can attend various technical training sessions at our company free of charge.

3. After purchasing the machine, we can send technicians to your country for installation and operation training.

4. You can provide your suggestions or inquiries through various channels, including phone, fax, mail, email, or website customer messages.

FAQ

Q1: What about the warranty period?

A1: Rest assured, if you encounter any issues with the main components of the machine (excluding consumables) during the warranty period, we'll swiftly replace or repair them at no extra cost.

Q2: I'm unsure which model best suits my needs. Can you help me decide?

A2: Certainly! Please provide the following information:

(1) The type of material you're working with.

(2) The thickness,width,length and material of your sheet.

(3) The cutting requirements you need.

Q3: What are your payment terms?

A3: We offer flexible payment options such as TT, Western Union, PayPal, LC, and Cash, among others.

Q4: Do you provide CE certification and other necessary clearance documents?

A4: Absolutely, we have all the essential original documents. Post-shipment, we'll supply you with the CE document, packing list, commercial invoice, and sales contract to facilitate customs clearance.

Q5: What should I do if I'm unfamiliar with the machine operation or encounter issues after receiving it?

A5: Don't worry, we provide a comprehensive user manual with detailed images and a USB disk to guide you step-by-step. Plus, we offer monthly updates to keep you informed on any advancements.

Q6: How can I obtain a sample to verify the quality and results?

A6: Simply send us your sample, and we'll conduct a free test for you.

Q7: When can I expect to receive a quotation?

A7: Your inquiry will be addressed with expertise and precision within 12 hours.

>> Grill utensil caddy Steel Caddy For Organizing Paper Towels, Condiments, bbq grill caddy

>> Tornocw61125q Cw62125q 1250mm Turning Diameter China Manufacturer of Horizontal Lathe Machine Engine Lathe Machine with Flat Bed 600mm with 2.5 Tons Load Lathe

>> Hot Selling Toothpaste Mixing Cosmetics Cream Ointment Mixer Equipment Homogenizer Reactor Foundation Lipstick Making Machine

>> 4ux-90 Tractor Accessories New Small Potato Harvester

>> Nike Air Force 1 Low Tiffany Braneded Shoes

>> Men′s Chest Custom Bag with Large Capacity Versatile Canvas Multifunctional Waist Bag

>> Automatic Discharging Coconut Oil Extraction Disc Stack Centrifuge

>> WEIKA Black slim UPVC frame customized glass new grill design casement/ swing door

>> YCAG YORK-003 in stock

>> Wholesale Empty 5ml 10ml 15ml 20ml 30ml 50ml 100ml Amber Glass Essential Oil Bottle with High Quality Dropper

>> Multi Use Powder Coated Black Steel Metal School Bunk Beds for Hotel

>> upvc hung window lock burglar proof vinyl single hung window mobile houses vinyl single hung anti deafth windows

>> Hot Sale Tungsten Carbide Nail Gripper Dies for Enkotec Nail Machine

>> Chinese Green Tea- Fuxi Tea for Sale

>> Customized Color Sanitary Napkin Machine with Fast Packing Features

>> Samsung Type-C USB Flash Drive 256g 128g 64GB Pen Drive USB 3.1 Type C Pendrive Memory Stick for PC/Notebook/Smartphone/Tablet

>> Mobile Two Stage Crusher for Rock Stone Quartz Silca Sand

>> Low Price Parallel Spiral Paper Core Tube Making Machine

>> High Efficiency Agricultural Machinery Peanut Picker Peanut Harvester Peanut Sheller

>> Reformer Tube Conversion Furnace Tube Radiation Tube Electric Resistant Furnace Petroleum Cracking Tube Resistant Cracking Furnace Tube for Petrochemical

>> Party Decoration Christmas Gift Battery Operated LED Candle Lights

>> Factory Woven Bag BOPP Bag PP for Rice 10kg 25kg 50kg Package Agriculture Gravure Printing

>> Customized! ! ! New Chinese Mini 3.5 3.5m3 Cubic Cement Machine Concrete Self-Loading Articulated Mobile Mixing Mixer Truck with Pump Machine for Factory Price

>> Hydraulic CNC Bending Machine Huafeng Press Brake and Angle Automatic Machine

>> 2WD and 4WD Reliable Quality Qsz 2400 Combine Harvester

>> 85 Inch Interactive Flat Panel Android 14 Whiteboard 4GB 32GB Touch Screen for Meeting Presentation

>> 1.8kw 24V DC Portable Super Silent Gasoline Electric Generator for Truck Bed Food Van Semi Trailer RV Motorhome Camping

>> Blow up Water Playground in Lake Inflatables on Water

>> Partition Doors Lowe tempered glass Sliding Doors Patio Double Glazing Toronto Aluminum Sliding Door For Interior And Exterior

>> Full Automatic 4~10 Lines V Fold Facial Tissue Folding Making Machine