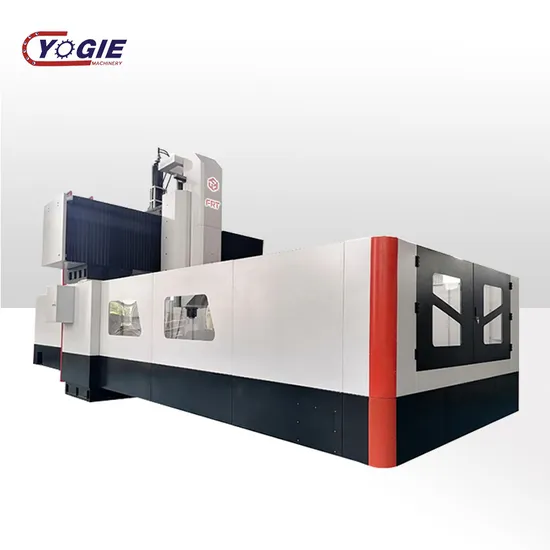

High Rigidity Milling Machine Frt3018 CNC Double Column Machining Center

| US$75,600.00-156,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

FRT-3018

Structure

Gantry

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

Precision

Certification

ISO 9001

Condition

New

CNC Operating System

Siemens/Fanuc/Knd

Working Table Size

3000*1500mm

Left and Right Stroke (X)

3000mm

Back and Forth Stroke (Y)

1920mm

up and Down Stroke (Z)

1000mm

Distance From Spindle End to Worktable S

170-1070mm

Spindle Taper

Bt50

Use Pull Stud Model

P50t-1

Spindle Speed (Rpm)

6000rpm

Machine Tool Positioning Accuracy (GB /

0.01

Repeated Positioning Accuracy of Machine

0.01

Spindle Power

22kw

Power Supply Requirements

380V

Machine Dimensions

8000*3000*3000mm

Number of Axes

3

Transport Package

Wood

Specification

Customized

Trademark

YOGIE

Origin

China, Henan

Product Description

Henan Front fixed beam and column CNC gantry boring and miling machine inherits the advantages of traditional gantry machine tools such as strong rigidity, symmetrical structure, andstrong stablity, and adopts innowative design concepis.All products adopt PROrE three-dimensionalc design. The main structure ofthe machine toolis unifom Using finite element analvsis,By opimizing the reinforcement structure and disitributing the quality reasonably, the whole machine has heavy load,strong rigidity, good dynamic characteristics, meets the requirements ofhigh-power and high-precision cuiting, and itis suitable for the processing ofsuper large and ultra heavy parts. Product Description

Product Parameters

| Item | Main Parameter | |

| CNC operating system | FANUC | |

| Worktable size | mm | 3000×1500 |

| Left and right stroke(X) | mm | 3000 |

| Back and forth stroke(Y) | mm | 1920 |

| Up and down stroke (Z) | mm | 1000 |

| Distance from spindle center to column guide | mm | 260 |

| Distance from spindle end to worktable surface | mm | 170-1070 |

| T-slot of worktable (Number/size/spacing) | mm | 6-26×150 |

| Spindle taper(model/sleeve diameter) | BT50/Φ155 | |

| Use pull stud modle | P50T-1 | |

| Spindle Speed(rpm) | rpm | 6000 |

| X axis ball screw specifications | mm | 63×16 |

| Y axis ball screw specifications | mm | 50×12 |

| Z axis ball screw specifications | mm | 50×10 |

| Machine tool positioning accuracy (GB/T 20957.4-2007 standard) | mm | 0.01 |

| Repeated positioning accuracy of machine tools (GB/T 20957.4-2007 standard) | mm | 0.01 |

| X/Y/Z axis rapid shift | m/min | 10/12/10 |

| Cutting speed | m/min | 8 |

| Spindle transmission mode | Synchronous toothed belt drive | |

| XYZ axis servo motor transmission mode and transmission ratio | X-axis reducer directly connected 4:1; YZ directly connected transmission Y-axis 1:1,Z-axis 1:1 | |

| X,Y axis guide specifications | X-axis four 55-gauge heavy-duty roller linear guides; Y-axis three 55-gauge heavy-duty roller linear guides | |

| Z axis guide specifications | Rectangle hard rail | |

| Square Ram Size | mm | 420×420 |

| Spindle power | KW | 22 |

| Recommended selection of servo motor parameters | N·M | 35/35/40 |

| Air source flow | >0.5 | |

| Power supply requirements | 380V | |

| Bed cushion height | mm | 30 |

| Workbench load bearing | kg | 8T |

| Machine dimensions | mm | 8000×3000×3000 |

| Light machine net weight | kg | 30t |

Company Profile

FAQ

Q:What is your minimum order quantity and warranty?

A:MOQ is one set, and warranty is one year.

Q:How can I choose the most suitable machines ?

A:Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

Q:What is the payment Terms ?

A:T/T ,50% initial payment when order ,50% balance payment before shipment ; Irrevocable LC at sight .

4.Can your company send the technical personnel to our company and direct our workers for free?

A:When the machine arrive the buyer's installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD200.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

>> 315/80R22.5 Joyall Factory Truck Tire for Drive Position TBR

>> High-Quality HOWO Truck for Sale - Used Concrete Mixer in Tanzania

>> Ready to Ship Cooking Oil Maker Sunflower Seed Sesame Oil Expeller Peanut Soybean Small Oil Press Machine Oil Extraction Machine

>> 2 Layers IBC Chemical Storage Tank Extrusion Water Tank Blow Molding Machine

>> Wholesale Pbat+PLA+Corn-Starch Drawstring Waste Bin Bag Roll

>> Advanced Re-Sharpening Machine for Precision Cutting Edge Renewal

>> 1/8 inch 3 way VM130-01-02 One side Pneumatic Roller Type Mechanical Valves

>> Waste Making Bran Wheat Straw Widely Used Long Grass Mill Feed Pellet

>> PP/PE/PVC/PA Plastic Single Screw Extruder

>> Sy-K005 Medical Kit First Aid Box Emergency Kit

>> Factory Direct Supply 6000Btu Wall Mounted Window Typw Window Air Conditioner O General

>> Sample Customization Injection Mold Maker Large Rattan Design PP Garden Plastic Table Stool Chair Mould

>> Brand equipment FSY Concrete Crack Depth Gauge for sale

>> Wholesale Cardboard Tea Coffee Cans Paper Tube for Food Packaging with Aluminium Metal Lid

>> St-72yt Smartlathe Bmt55 Knurling CNC Lathe Machine

>> Home Care Medical Seat Cushions

>> China Trustworthy Factory 4000kg Hairline Stainless Steel Cargo Warehouse Parking Car Lift

>> Plastic Bottle Film Shredder Pet Crusher Plastic Recycling Machine

>> Abs Double Color Sheet Abs Textured Plastic

>> PP Woven Bag Four Shuttle Circular Loom Machine

>> Car Front Fog Lamp Cover Auto Parts Front fog light trim cover for hyundai Elantra 2014 R 86564-3X7000 L 86563-3X7000

>> Taijia fixed ultrasonic flow meter ultrasonic flowmeter for river ultrasonic water flow meter clamp-on ultrasonic flow meter

>> D1649 Performance Quality Ceramic Auto Parts Front Brake Pads for INFINITI

>> Hanbs Hot Machine Model W20/15 Swiss Type CNC Lathe in High Rigidity and Accuracy

>> Good Quality Crusher Spare Parts Suitable for Jaw Crusher and Cone Crusher/OEM CH440 442.8821-05

>> Merv 8 G4 Disposable Panel Primary Filter with Cardboard Frame

>> Hot Selling 58kHz Am System EAS Retail Shop Security Supermarket Security Door

>> Factory ANSI/GOST/Duplex/ Ss/CS /Weld Neck Slip on/Blind/Threaded/Socket Weld/Plate/Spectacle Blind/Lwn/Orifice/Anchor Flange

>> Shandong Small Tillage Cultivator Ditching Machine with 3tg-4q-C Model

>> Core Filling Inflating Snacks Machine Line