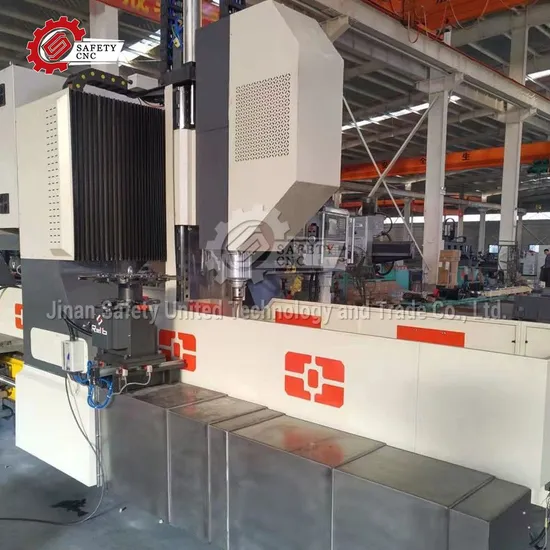

Customized Phd Series Phd Series Gantry Movable CNC High-Speed Drilling Machine

Basic Info.

Model NO.

PHD Plate Drilling and Milling Machine

Controlling Mode

CNC

Number of Shaft

3

Hole Diameter

151-200mm

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Thickness

150mm-100mm

Quan. of Spindle

1

Model of Spindle

Bt50

Max. Drilling Diameter

50

Speed of Spindle

30-3200 (R/Min)

Feeding Stroke

350 (Servo Feeding)

Tapping Diameter(mm)

M26

Clamping Mode

Manual

Spindle Motor

15(Servo Motor)

Precision of Positioning

0.04/500 mm

Precision of Repeating Positioning

0.03/500

Chip Removal

Chain Flat

Quan. of Chip Removal

1PCS

Speed of Chip Removal

1m/Min

Power of Motor of Chip Removal

0.75kw

Transport Package

Standard Shipping Packaging or Customized

Specification

Standard or Customized

Trademark

PINGANLIANSHENG

Origin

Jinan, China

Production Capacity

50000 Net/Years

Product Description

Customized PHD Series Phd Series Gantry Movable CNC High-Speed Drilling MachineProduct Description

Apply scope:

The machine is mainly used for drilling and milling connecting plates in steel structures, iron towers, bridges, mechanical processing industry, as well as the tube plate, baffles, flange, and others in industry boilers, petrochemical, pressure vessels, and so on.

Drilling Tapping Milling Tool inner cooling

Drilling Mode

Light Milling Mode

Product structure:

This machine is mainly composed of a bed, gantry, drilling and milling power head, electric control system, centralized lubrication system, cooling system chips removal system, etc.

The characteristics: 1. The base and gantry of the equipment are welded from a steel structure. Sufficient heat treatment is carried out to eliminate internal stress. Therefore, the dynamic and static rigidity is excellent, and the deformation is very small.

2. On the longitudinal movement direction of the gantry two high load-bearing linear rolling guide rails are on both sides of the base, so ensure the flexible movement. On the double side adopt an AC servo motor and precision ball screw pair for the synchronous drive, to ensure high positioning accuracy and repeated positioning accuracy.

3. The Y-axis movement is guided by two linear rolling guide rails, driven by AC servo motors and precision ball screw pairs to ensure high precision of work.

4. This machine adopts a vertical CNC feeding slide drilling head, which is driven by a YPNC-B series spindle-specific variable frequency motor through a synchronous belt. The speed ratio is 1:2, and the low-speed torque is large. It can withstand heavy cutting loads and is also suitable for high-speed machining of hard alloy tools.

5. The drilling spindle adopts a precision hollow internal cooling spindle with a BT50 taper hole and a butterfly spring automatic tool-pulling mechanism, making tool replacement very convenient. It can be used to clamp carbide internal cooling bit and high-speed steel Fried Dough Twists bit and has the function of purging and cleaning the spindle taper hole.

6. Equipped with pneumatic knife cylinder automatic knife replacement, optional tool magazine.

7. The workbench is mounted on a base, and there are T-shaped groove bars, on which workpieces can be fixed with the pressure plate.

8. The CNC control panel is installed on the gantry and can move longitudinally with the gantry, so that easy to operate. The CNC system of this machine adopts the KND CNC system which is equipped with an RS232 interface and LCD display screen. It is managed by the upper computer, and the drilling coordinates can be directly converted into CAD/CAM, which facilitates programming, storage, display, and communication.

9. The operation interface has functions such as human-machine dialogue, error compensation, and automatic alarm. The hole position of the workpiece can be automatically generated into a machining program through a keyboard or CAD floppy disk input. Equipped with pre-drilling hole position prediction and re-inspection functions, easy to operate.

10. This machine is equipped with a flat chain automatic chip conveyor and a chip collecting trolley, and it is equipped with a high-pressure internal cooling pump, which can be used for internal or external cooling of the tool. The coolant can be recycled.

Automatic tool change. Disc type or Linear type

The tools can be evenly suspended on the ACT rack, so that the knife will not rub, ensuring the service life of the tools.

The gap between the knives is obvious, making it easy to remove and put them back,

The tool storage density is high, allowing for the placement of more tools, saving workspace, and improving efficiency. Technology Parameter

| Model | PHD1616 | PHD2016 | PHD2020 | |

| Processing size | LxW(mm) | 1600x1600 | 2000x1600 | 2000x2000 |

| Thickness(mm) | 15-100 | |||

| Drilling spindle | Quan. of spindle | 1 | ||

| Model of spindle | BT50 | |||

| Max. Drilling diameter | Φ50 | |||

| Speed of spindle(r/min) | 30-3200 | |||

| Feeding stroke(mm) | 350(Servo feeding) | |||

| Tapping diameter(mm) | M26 | |||

| Clamping mode | Manual | |||

| Power of motor | Spindle motor(KW) | 15(Servo motor) | ||

| X-axis(KW) | 2×1.6 | |||

| Y- axis(KW) | 2.4 | |||

| Z- axis(KW) | 2.4 (with brake) | |||

| Precision of positioning(mm) | 0.04/500 | |||

| Precision of repeating positioning(mm) | 0.03/500 | |||

| Control mode | KND CNC system, model: KND1000 | |||

| Chip removal and cooling method | Chip removal | Chain flat | ||

| Quan. of chip removal | 1pcs | |||

| Speed of chip removal | 1m/min | |||

| Power of motor of chip removal | 0.75KW | |||

| Power of motor of inner coolant | 4KW | |||

| Auto. lubrication | Lubrication pressure | 2MPa | ||

| Oil of lubrication point | 0.1ml | |||

| Weight of machine(T) | 7 | 10 | 13 | |

| Dimension(m) | 3800x2050x2750 | 4200x2450x2750 | 4200x2850x2750 | |

| Optional- Tool magazine | 6units of Straight tools | |||

| Optional- automatic clamp | 12 units of hydraulic clamper | |||

Company Profile

FAQ

Q1: Are you a manufacturer or trading company?

A1: We are a manufacturer.

Q2: Can the machine parts be changed according to my requirements?

A2: Yes, we will try our best to give you the best products.

Q3:What is your payment term?

A3:30% T/T deposit paid in advance, 70% balance paid before shipping.

Q4: How can I get to your factory?

A4:We could pick you up at the airport or high-speed rail station.

Q5: What service can you provide before order?

A5:About the pre-sale service. We provide you answers to all your questions on our machines, such as technical parameters, price, payment terms, etc. If you wanna visit our factory and check the machines, we also can send you an invitation letter and give you our warmest welcome.

Q6: Can you finish the machine during the delivery time?

A6:We will finish the machine in time according to the determined lead time.

>> 10 Inch 300W High Performance New Fashion Home Theater Active Heavy Subwoofer Active Speaker for Arbitrary Connection

>> Liquid Fertilizer Calcium Thiosulphate

>> Water Cooling ISO 9001 Approved Inte Aluminum Sheet Drill Machine

>> Factory galvanized steel stucco wire mesh with professional experience

>> Protect your cells from oxidative stress three-in-one 300ml Hydrogen Gas Inhalers 150ml Hydrogen Gas Inhalers

>> Cryo Body Shape Cryolipolysys 4 Handles 360 cryolipolyses Fat Cell Body Slimming Machine Criolipolisis

>> Women Ladies′ Rain Jacket Dust Coat with Mesh Lining Windbreaker

>> IP/WiFi Touch Screen System Smart Wireless Remote Control Video Doorphone Intercom

>> Package Lab Consumable PP Disposable Medical Supplies 1250UL 96 Wells Pipette

>> Sasuke Uchiha Kusanagi Sword Shirasaya Anime Cosplay Samurai Katana

>> High pressure Nexiva diffusics IV catheter, BD IV catheter sindy@antmed.com

>> Breathable Anti-Static Non-Woven Disposable Bed Sheet/Pillow Cover Hospital Bedding Set

>> 84"Stainless Steel Rolling Tool Chest

>> Ybx4 Three-Phase Asynchronous Electric Motor for Industrial Chemical Industry Ex Motor

>> Laminating Machine for Plastic Photo Frame Hot Foil Stamping

>> Plastic Buoy and Pontoon Float Box Blow Molding Machine High Automation Stable Performance

>> 1-5tph China Manufacture Chicken Cattle Livestock Fish Poultry Pig Animal Feed Pellet Mill Feed Pellet Making Machine

>> Factory Direct Sale Biomass Waste Extruder Bagasse Olive Waste Extruder for Briquette Press Machine

>> Customized Logo Design Pattern Pure 100% Silk Woven Jacquard Necktie Formal Business Men Tie

>> Plastic Bottle Canister Making Drum Extrusion Blow Molding Machine

>> OEM custom logo food white sealed packaging waterproof ldpe food frosted packaging plastic zipper lock bags for snacks

>> Taijia Dual Channel Ultrasonic water flow meter portable industrial fuel flowmeter flow meter diesel

>> 1/2" Bsp Female Thread Bronze or Brass Accepted Y Strainer with SS304 Filter

>> Intelligent PP Portable Basketball Sport Court Plastic Tiles Temporary Basketball Flooring Outdoor

>> CE Approved Farm Use Flat Die Biomass Granulator

>> Stainless Steel Automatic Backwash Filter Self-Cleaning Filter for Industrial Water Treatment

>> Bh Automatic Roll Forming Machine for Multi-Shape

>> Construction Machine Mixing Concrete Batching Plant

>> S5500V2-Ei Ethernet Network Switch High-Performance Converged Mainnet Switch

>> JXZH-700 Cotton Ginning Machine