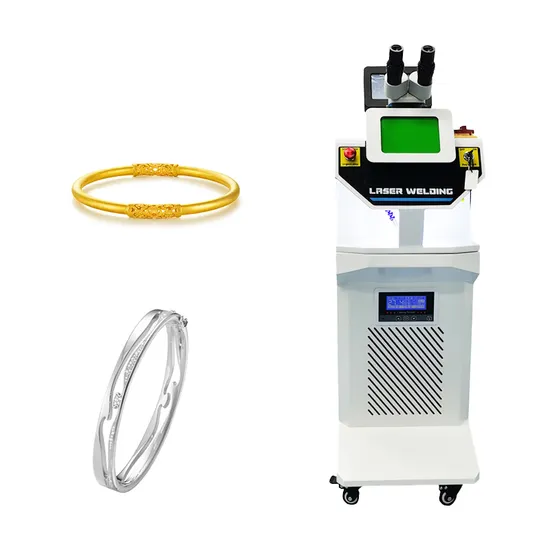

YAG Spot Mini Jewelry Welding Machine Metal Stainless Steel 150W Laser Welder and Solder Machine for Necklace

| US$2,890.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DW-200W

Application

Biomedicine, Electronic Industry, Automotive Industry, Powder Metallurgy, Manufacturing Industry, Jewelry Repair

Technical Class

Pulse Laser

Control

Manual

Power Density

Heat Conduct Welding

Laser Classification

YAG Laser

Type

Jewellery Laser Welding Machine

Product Name

Jewelry Laser Welding Machine

Max Output Power

500W

Laser Spot

0.2-0.3mm

Welding Depth

0.1-3mm

Single Pulse Energy

60joules

Wavelength

1064nm

Cooling Method

Water Cooling

Certificated

CE FDA

Power

200W

Transport Package

Wooden Box

Specification

125*78*45CM

Trademark

DOWIN

Origin

Zhengzhou China

HS Code

8456110090

Production Capacity

500sets/Month

Product Description

yag spot mini jewelry welding machine metal stainless steel 150w laser welder and solder machine for necklace200W laser jewelry spot welder welding machine widely used for jewelry, golf head, medical instrument, instrument, electronics, machinery, automobile, etc,especially for the perforating of gold and silver jewelry, wedding ring , necklace etc repair and weld

YAG Laser Welder Main Features yag spot mini jewelry welding machine metal stainless steel 150w laser welder and solder machine for necklace 1. Water cooling system : Internal integration water cooling system , make the machine size much smaller , keep the machine working in suitable temperature always

2.Microscope : with microscope , improve the machine precision welding ability , specially for extremely fine and small parts ,like prongs, settings, and delicate chains, without damaging nearby areas

3.Display :display the welding effect at all times, with color ful , make sure the welding much easier

4.Easy to operate :Without special request for the operator , very easy to learn , save time , improve welding speed

Application area :

yag spot mini jewelry welding machine metal stainless steel 150w laser welder and solder machine for necklace Used for precision welding of hardware, kitchen and bathroom industry hardware (faucet and round pipe welding, kitchen sheet metal parts, washing machine inner tube welding, etc.) and electronic industry (mobile equipment) precision hardware welding. Phone, tablet, car, etc.)

Applicable materials:

It can meet the welding of various metals, alloys, steel, Kovar alloy and other same materials, as well as the welding of copper nickel, nickel titanium, copper titanium, titanium molybdenum, brass copper, low carbon steel copper andother dissimilar metals.

>> CNC Router for Stone Multifunctional Processing Center CNC Carving Cutting Machine

>> Modified full led headlamp headlight with streamer turns and with a touch of blue function for Jeep Wrangler JL 2018-2021

>> Veneer Knife Grinding Machine

>> 1m*10m PVC Mesh Net for Motif Lights Making Christmas Decoration Lights

>> Commercial Halloween Haunted House Inflatable Maze for Sale

>> 1.82 Density of Molded Graphite Plate for Sintering Industry

>> High Quality European Standard Taper Bore Taper Bushed Type Synchronous Timing Belt Pulley Wheel

>> Industrial Rice Straw Reed Mat Weaving Machine Straw Mat Making Machine Grass Stalk Wheat Straw Curtain Sewing Knitting Machine

>> Custom Logo Cardboard Gift Sliding Box Drawer Paper Box With Clear Window for Flower Packaging

>> End Mill Sharpening Machine with Carbide Wheel Mr-X1

>> Fastest China to Europe Truck/Road Transportation Shipping From China to Luxembourg/ Monaco/Portugal/Sweden

>> Intelligent Logistics Conveyor System Code Scanning Dimension & Weight Measuring Dws Equipment

>> Ttn Hot Sell Wholesale Price Offline UPS Power Bank Supply

>> Custom Black White Bronze Color Double Glass Window Aluminium Frame Sliding Glass Window

>> Iseki Top Level Head Feed Combine Harvester

>> Hot Linear Lamp Pixel Strip DMX COB Wall Washer Lighting Price 10*45W RGB 3in1 LED Matrix Bar Beam Wall Wash Stage Light

>> 120d/2 High Tenacity 100% Polyester Manufacturer Glossy Embroidery Thread for Machine Embroidery

>> Gedeli Bifolding Windows Horizontal Slide Folding Window Aluminium Bifold Window

>> 1.5-12oz Disposable Paper Cup Machine

>> Aoma Otesaly 100iu 150iu 200iu Anti Wrinkles Deep Lines Removel Toxins Injection

>> Adk Servo Motor Absolute Encoder 23bit/25bit Ts5700 with Tamagawa/Ssi and Biss Protocol

>> Ancient Dragon Maiden Doll 1/3 BJD Doll with Joint Movement

>> Block wire saw machine with ce certificate

>> Factory Commercial Cotton Candy Floss Sugar/Candy Floss Machine with Cart

>> Costomized Festival Lantern Chinese New Year Animal Lantern Leopard Silk Lantern Festival

>> Cement silo bottom crushing valve Electric double-shaft crushing valve Block breaking valve

>> Made in China Professional Big Drone Jamer Counter Uav System Anti Jammer Price

>> wholesale bulk fishing reels carp long cast carbon fishing reel

>> Luxury Logo Printed Satin Ribbon Foil Gold Polyester Ribbon Manufacturer

>> Automatic Concrete Cement Hollow Block Solid Brick Paving Tile Making Machine