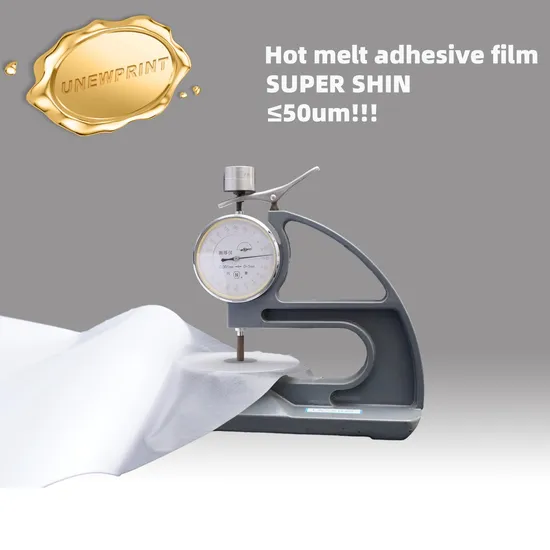

Super Ultra Thin 15um-50um Hot Melt Adhesive Film for New Energy Automotive with New Material

| US$2.50-3.50 | 30 Square Meters (MOQ) |

Basic Info.

Model NO.

EEA

Application

Automobile, Construction, Woodworking, Footwear & Leather, Fiber & Garment, Packing, Electronic Product

Material

Eea

Classification

Hot Melt

Main Agent Composition

Eea

Color

Clear

Melting Point

110degrees Centigrade/230degrees Fahrenheit

Thickness

15micron,

Bonding Temp.

130-140degreescentigrade/266-284degrees Fahrenheit

Trademark

UNEWPRINT

Origin

Zhejiang, China

Production Capacity

10000 Rolls/Month

Product Description

Product Parameters Product Name: Super-thin Hot Melt Adhesive FilmProduct Parameters

| Model No. | Thickness | Melting point | Bonding Temp. | Application |

| Base:Release Liner PET Coating:TPU | 30µm,5µm | 100-120°C/212-248°F | 100-130°C/212-266°F | Cotton,PET, Leather,Polyester |

| Base:Release Liner Paper Coating:EAA | 10µm,20µm | 80-90°C/176-194°F | 90-100°C/194-212°F | Metal,Paper,Cotton |

| Base:PEN Coating:EEA | 15µm | 110°C/230°F | 130-140°C/266-284°F | Metal,PET,PEN,PEI |

| Base:EI Coating:EEA | 15µm | 110°C/230°F | 130-140°C/266-284°F | Metal,PET,PEN,PEI |

| Base:Release Liner Paper Coating:PES | 30µm | 90°C,110°C/194°F,230°F | 100°C,120°C/212°F,248°F | Cotton,PET,Leather,Metal |

| TPU/PES | 30-50µm | 100°C/212°F | 120°C/248°F | Any material suitable for TPU and PES |

| Base:PET Coating:PU | 30µm | 90-100°C/194-212°F | 100-120°C/212-248°F | High Transmitting Anti-Yellow PU |

After extensive research, we've developed an unparalleled series of super-thin hot-melt adhesive films.

Our super-thin hot-melt adhesive films stand out in the market with a thickness ranging from just 5-50μm (0.005mm-0.05mm). These films are known for their smooth surface, high structural strength, and exceptional anti-yellowing properties.

We've pioneered a unique technology to produce a revolutionary film featuring different materials on each side, enhancing service quality for our clients.

| Product | EEA | |

| Technical Parameter | Thickness(micron) | 15micron |

| Melting Point(°C/°F) | 110°C/230°F | |

| Bonding Temp.(°C/°F) | 130-140°C/266-284°F | |

| Specification | Roll | 3" paper core |

| Width | Customization | |

| Length | Customization | |

| Application | PEN,PEI,PET,metal,etc. | |

| Support Customization & OEM | ||

| EAA FILM/PAPER RELEASE BASE | EAA FILM/PET RELEASE BASE |

| PES FILM/PAPER RELEASE BASE | EEA FILM/PEN BASE |

| TPU FILM/NON-WOVEN FABRIC BASE | TPU FILM/PET RELEASE BASE |

| PES/TPU FILM(2-Sided Different Material Film)/PET RELEASE BASE |

| Aerospace | Car Decoration | PPE Suit |

| Mobile Phones | Industries | Medical |

Backed by robust R&D capabilities, our company was recognized as a national high-tech enterprise in 2012.

Our unwavering commitment to excellence ensures that we exceed customer expectations by adhering to production standards superior to international benchmarks. R&D Capability And Patents

Packing & DeliveryFAQ 1. Who are we?

Established in 2002, we are strategically located in Zhejiang, China, with proximity to Shanghai and Ningbo seaports.

Our factory operates with a dedicated team of approximately 11-50 employees.

2. Are you a factory manufacturer?

Absolutely, we are a factory manufacturer.

3. What can you buy from us?

-- Digital print heat transfer consumables: including Cotton inkjet heat transfer paper, DTF ink/film/powder, Eco-solvent ink printable heat transfer vinyl, Eco-solvent ink printable sticker paper, Heat transfer film, Heat transfer vinyl;

-- 5-50μm super-thin hot melt adhesive film;

4. Why should you choose us over other suppliers? We ensure rigorous quality control during mass production.

We offer comprehensive customization & OEM services.

Our strong R&D capability, coupled with over 20 years of rich experience, benefits our customers immensely.

Feel free to contact us if you're interested in purchasing our premium products or developing new products.

Tips: Kindly test our materials before mass production, as we do not cover any losses beyond our material specifications.

>> Anon High Quality Walk Behind Mini Wheat Rice Reaper Machine

>> Manufacturer Wholesale Dyeing and Printing Computer Paint Color Tinting Machine

>> High Quality Mining Drilling Bit High Air Pressure DTH Hammer Drill Bit DTH Button Drill Bits for Mining

>> Durable Clear Clothes Hangers Plastic Coat Hanger for Adult Closet with Swivel Hook

>> Portable Fashion 1: 1 Clothing Brands Designer Brand Fashion a Two-Piece Luxury Ladies Famous Brand Clothing

>> Kb520 5g Industrial Router Compatible with 5g/4G/3.5g/3G/2.5g Networks 2 * 10/100Mbps Fast Ethernet Interface 5g Router

>> 84522858 front grille FOR Cadillac XT4 2018-2019

>> Large Plastic Garden Plastic Flower Pots Planters for Home Decoration

>> Lawn Mower Spindle Assembly Replaces Cub Cadet/Mtd 618-06979, 918-06979

>> Purified Sweet Natural Dried Sliced Mango

>> Concrete Wetcast Paver Block Demoulding Precast Curbstone Machine Veneer Stone Production Line

>> High Quality Heavy Duty Hydraulic Radial Drilling Machine

>> Fixtec Large LCD Screen Clear Reading Digital Multimeter Tester with Overload Precision Industrial Quality Digital Meter

>> Good Quality Old Fresh Ginger From China, Direct Ginger Farm

>> Ck6166 CNC Floor-Type New Kd CNC Flat Bed Lathe Machine

>> High Output Waste Plastic Recycle Crushing Machine Injection Mold PP PE Pet Bottles Crusher Machine Price

>> High Quality 1kw/2kw/3kw/4kw Full Closed Fiber Laser Cutting Machine for Cutting Heavy Metal Sheets

>> Grinding Powder Making Machine Grinder Mill Equipment

>> New Material Cpet APET PETG Sheet Recycling PP Recycled Material Scrap Used Plastic RPET Sheet Sheet Extrusion Making Machine

>> PLC Automatic Chain Link Fence Machine From China

>> 300m Fiberglass Cable Guide Roller 14mm FRP fish tape / fiberglass cable snakes duct rodder

>> T3 Series Residential &Industrial Ultrasonic Flow Water Meter Water Supply Remote Control System

>> Professional Custom High-Quality Fashion PU Belt Jeans Belts with Elastic

>> Professional Waste Tyre Crushing Machine Tire Grinder Tire Recycling Machine

>> Brand New Customized Version Dongfeng 4X2 Chassis Compression Garbage Truck

>> Flooring Protection Floor Tile Decoration Ceramic Tile Porcelain Tile Flooring Tile Painter Felt Vinyl Flooring Carpet

>> Australia Standard Powder Coated Heavy Duty Vet Cattle Yard Crush

>> CNC High Speed Drilling Machine for H Beams and Box Beams

>> OEM Monochrome Graphic LCD Display Cog Type 128*64 Graphic LCD Module with Controller St7565r, FPC 15pin for Industrial. Medical. Equipment.

>> Wholesale Large Capacity Makeup Wash Bag New Travel Fashion Cosmetic Bag