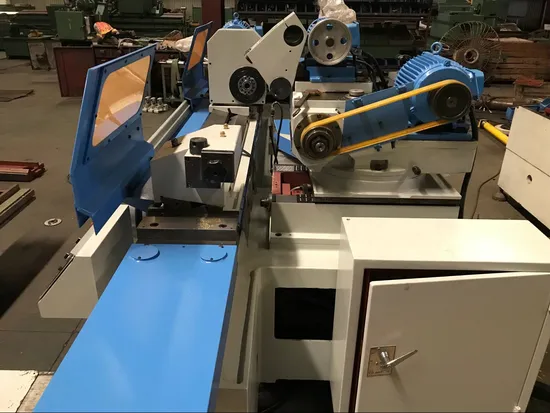

Universal Cylindrical Grinding Machine M1420/550

| US$11,200.00-13,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

M1420/550

Controlling Mode

CNC

Automatic Grade

Automatic

Cylindrical Grinder Type

Universal Cylindrical Grinder

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Grinding Length(O.D/I.D)

1000/125

Grinding Dia.(O.D/I.D)

8-320/30-100

Center Height

180

Max.Workpiece Weight

150mm

Transport Package

Wooden Case

Specification

Grinding Length(O. D/I. D)1000/125

Trademark

WHITE EAGLE

Origin

Made in China

HS Code

8460199000

Production Capacity

1000 Sets / Month

Product Description

Application and FeatureThe machine is intended for cylindrical, internal and taper grinding. It is specially suitable for workshops engaged in single-piece, small and medium batch production.

The workpiece, cylindrical and internal grinding wheels, hydraulic and coolant pumps are driven by their separate motors.

The table longitudinal traverse is actuated by hydraulic means at steplessly variable speed or operated by means of handwheel.

The wheelhead rapid approach and withdrawal and intermittent feed are effected hydraulically. The wheel feed can also be operated by hand.

Specification

| Universal cylindrical grinding machine | M1420-520 |

| Diameter of grinding | Ø8~200mm |

| Maximum grinding length | 520mm |

| Grinding bore diameter | Ø10~80mm |

| Grinding depth | 125mm |

| Speed of internal mold | 11000r/min |

| Maximum spindle load-bearing | 50kg |

| Maximum travel of working table | 550mm |

| Speed of working table | 100~4000mm/r/min |

| Rotary angel of working table | -5~+9° |

| Rotary angel of headstock | -30~90° |

| Rotary angel of grinding wheel | 180° |

| Center height | 125mm |

| Center sleeve taper | MT4 |

| Grinding wheel size | 400*40*203mm |

| Speed of headstock | 60,85,230,120,170,460r/min |

| Speed of grinding wheel | 1780r/min |

| High-speed travel of grinding wheel | 20mm |

| Maximum travel of grinding wheel | 150mm |

| Feeding rate of grinding wheel handwheel per grid | 0.005mm |

| Feeding rate of grinding wheel handwheel per rev | 1mm |

| Power of grinding wheel motor | 4kw |

| Power of headstock motor | 0.25/0.37kw |

| Power of oil pump motor | 0.75kw |

| Power of cooling motor | 0.125kw |

| Dimension (length * width * height) | 2200*1450*1650 |

| Weight | 2500kg |

| Roundness 0.002mm Cylindricity 0.003mm Roughness Ra0.32 | |

Standard Accessories

| Item | Name | Model/Drawing No. | Specifications | Amount | |

| 0 | Universal cylindrical grinding machine | M1420 | 520 | 1 | |

| 1 | Waterproof cover | M1320-25-315 | 1 | ||

| M1320-25-316 | 1 | ||||

| J21-4 | M16×10 | 2 | |||

| 2 | Tension spring | M1320-25-314 | 2 | ||

| 3 | Triangle roller box | M1320-25-501 | 2 | ||

| M1320-25-304 | 56 | ||||

| 4 | Flat roller box | M1320-25-502 | 2 | ||

| M1320-25-305 | 28 | ||||

| 5 | Set screw with flat | J22-3 | M6×12 | 8 | |

| 6 | Drive the block | M1420-21-306 | 1 | ||

| J21-4 | M6×10 | 2 | |||

| 7 | Wedge belt | J type | 620×19.2 | 1 | |

| 8 | Triangle tape | O type | 710 | 1 | |

| 9 | Wedge belt | L type | 1024×19.2 | 1 | |

| 10 | Rubber belt | M1420-30-503 | 930×25×1.2 | 1 | |

| 11 | Grinding wheel dresser | M1320-61 | Diamond clamping | 1 | |

| 12 | Cooling water tank | M1320-76 | 1 | ||

| 13 | Inner grinding shutter | M1420-83 | 1 | ||

| 14 | Internal joint shaft | M1420-31-301 | 1 | ||

| M1420-31-308 | 1 | ||||

| M1420-31-310 | 1 | ||||

| M1420-31-313 | To spin | ||||

| 14-1 | Internal grinding wheels | M1420-31-300 | adhesion | ||

| GB80ZR1AP | 30×25×10 | 1 set | |||

| M1420-31-309 | Combined wheel bolt | adhesion | |||

| MGB60ZR1AP | 12×16×5 | 1 set | |||

| M1420-31-300 | Combined wheel bolt | adhesion | |||

| GB80ZR1AP | 17×20×6 | 1 set | |||

| M1420-31-500 | Paper pad | 1 | |||

| GB80ZR1AP | 40×25×13 | 1 | |||

| 15 | Mat iron | 3 | |||

| 16 | Wrench | M1320-85-301 | 1 | ||

| 17 | Dismounting nut | M1320-85-302 | M68X2 | 1 | |

| 18 | Hexagon socket wrench | M1320-25-501 | 1 | ||

| 19 | Double-headed wrench | S91-1 | 12×14 | 1 | |

| 17×19 | 1 | ||||

| 22×24 | 1 | ||||

| 27×30 | 1 | ||||

| 20 | Inner hexagon wrench | S91-7 | 5 | 1 | |

| 6 | 1 | ||||

| 8 | 1 | ||||

| 10 | 1 | ||||

| 12 | 1 | ||||

| 21 | Grinding wheel clamp | M1320-30-103 | 1 | ||

| M1320-30-307 | 1 | ||||

| M1320-30-308 | 5 | ||||

| J21-9 | M10×40 | 6 | |||

| J22-4 | M8×10 | 5 | |||

| 22 | Carbide-tipped center | HQ95-1 | A3 | 1 | |

| 23 | Half-conical center | HQ95-3 | A3 | 1 | |

| 24 | Screw driver | 4" | 1 | ||

| 25 | Right waterproof cover | M132-10-312 | 1 | ||

| 26 | Balance shaft and nut | M1320-85-300 | Ø50 | 1 Each | |

| 27 | Flange | M1420-62-300 | 1 | ||

| 28 | Three jaw chuck | M1420 | 1 | ||

| 29 | Internal grinding attachment | M1420 | 1 |

Technical Documents

| Name | Amount | Remark |

| Operational instruction | 1 | Accessory box |

| Test certificate | 1 | Accessory box |

| Packing list | 1 | Accessory box |

Machine Photos

Factory Capabiltiy

>> HIMA F6705

>> Premium Bridge Stone Polishing Machine for Quartz and Artificial Stones

>> Customized PP Plastic Sheet PP Board with Smooth and Flat Surface

>> Plastic UHMWPE HDPE Large Construction Road Mat Temporary Road Mats for Car Parking

>> 180-500 Degrees High Temperature Adjustable Solder Tool LED Digital Display Electric Soldering Iron with Power Switch

>> Huafon Good Leathers Soft Fake Full Grain Leather for Sandals Shoes Bags

>> Four-Row No-Tillage Corn Planter with Pneumatic Seeder Function

>> D50: 1-25um Ultrafine Powder Dry Grinding Fluidized Bed Air Jet Mill

>> Stone 1530 CNC Engraving Machine

>> Automatic Eyelet Pressing Machine for Pressing Eyelets Tightly on Fabrics

>> Hengxing Factory Supply Food Additives Blend Phosphate T2185 For Cheese Processing

>> 635nm Red Light Laser Weight Loss Non-Invasive 532nm Wavelength 6D Laser Emscooling Slimming Machine

>> 30FT 9m Double Decker Luxury Pontoon Boat for Sale

>> Truck Type Hydraulic Lifting Platform Equipment Steel Structure Plant Roof Construction Source Factory Support Customization

>> Bamboo Knife Fork Spoon Cutlery Set

>> Easy to Operate Safety 200W Power Electronic Wheel Chair

>> Winter Female Hundred Students Light Version Knit Hat Male Fashion Warm Cold Hat Thickened Ear Protection Woolen Hat Knitted Beanie Hat

>> Vertical Rotary Table Injection Molding Machine for Watch Strap

>> 43" Plastic Base Frameless AI-Powered 4K LED TV Televisions Smart

>> IP66 2 Years Warranty Outdoor Area Lighting Slim Design 150W LED Street Light

>> Baby 3 Wheel Child Bike Toy with Push Handle Baby Tricycle

>> New Fishing Bag Waist Shoulder Bags Reel Lure Storage Bag Fishing Tackle Pesca MULTI-PURPOSE Canvas Multifunctional Outdoor

>> Kitchen Counter-Large Capacity Bread Storage Container Bamboo Bread Box with Window

>> Wan Beardsley Compressors 75kw 100HP Pm Motor Variable Frequency Energy Saving Screw Air Compressor

>> Chinese Manual Milling Machine X5036 Cheap Knee Type Vertical Milling Machine

>> EB S1E Electric Motorbike EEC L1 NCM Lithium 500W/750W LUYUAN electric vehicle electric bicycle

>> FL-1080P Waterproof Car Side View Camera Vehicle Camera

>> DJ-89 LCD Dental 3D Printer Resin 3D Printing Machine

>> 2 sections solid transparent fiberglass 100-200g lure weight boat fishing rod with special design

>> Modern Multi-Functional Storage Cabinet for Home and Office Wooden Furniture