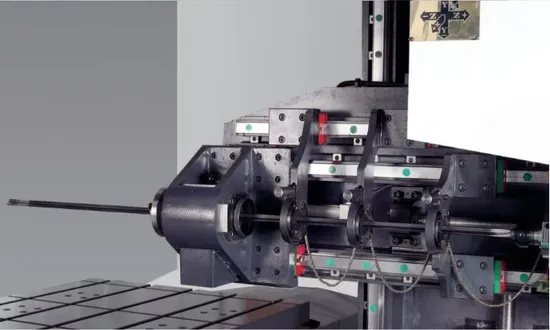

3 Axis Deep Hole Drilling Machine Gun Drilling Machine

| US$7,500.00-45,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

A06-0606

Application

Metal

Process Usage

Metal-Forming CNC Machine Tools

Movement Method

Contour Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.8-200mm

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001

Condition

New

Keywords

Deep Hole Drilling Machine

Drilling Aperture

3-20mm

Drilling Depth

600mm

Transport Package

Plywood

Specification

4200*2600*2300mm

Trademark

ubright

Origin

Cn

HS Code

8207509000

Production Capacity

60 Set/Month

Product Description

PRODUCT FEATURESThree coordinates NC linkage runs automatically;

Slender deep hole machining process without return, drilling efficiency is as high as 6 times more than ordinary drilling machines;

Processing aperture range, gun drill: 30-35 mm, BTA: 30 18-65-mm (BTA is optional);

Unilateral processing depth of up to 2500 mm, length to diameter ratio of 100 or higher;

With the ideal size accuracy, hole drilling accuracy of straightness, and roughness.

Product application:

At present, deep hole drilling is mainly used in the industries as following:

1,Mould industry: water line hole, thimble hole, ejection pin hole, electric hole, inclined hole, etc.

2,Hydraulic machinery industry: valve, distributor and pump, etc..

3,Automotive industry: cylinder, fuel supply system and other parts

4,Aerospace industry: the propeller, landing gear and other parts.

5,Chemical and generator industry: heat exchange parts.

6,ln the future, deep hole drilling will be more widely used in different fields, and will have more excellent performance.

Technical Specifications

>> Premium Upright Fire Sprinkler Head for Enhanced Safety

>> Heavy Truck Van DPF Clean Other Car Care Cleaning Equipment Doc/SCR/Fap/DPF Diesel Particulate Filter Regeneration Cleaning Machine

>> Men Sports Half-Finger Fitness Non-Slip Gym Dumbbell Weightlifting Bench-Press Wrist-Protector Climbing Gloves

>> Cheap Price Factory Direct Sale Body Kit Rear Head Lamp Headlight 81130-0r030 81170-0r030 for RAV4

>> Siecc Bran High Precision Lathe Machine

>> 7mm PVC Ceiling Gypsum Board False Ceiling Price with High Quality

>> 1" Bronze Water Meter Accessories

>> Automatic Steel Nail Making Machine Price, Concrete Nail Manufacturing Machine

>> 48V 5500W 500V PV Input Hybrid Solar Inverter WiFi and Parallel Supported

>> 150g 200g Crude almonds Nut Granule sachet automatic Packing Machine

>> New Technology PP HDPE Plastic Recycling Machine China for Small Scale Plastic Recycling Plant

>> 2020 High Precision Top Side of Saw Blade Grinding Machine for Top Side

>> High precision XKW715 Universal Bed Type Milling Machine

>> High Elastic Comfortable Postpartum Pelvic Compression Women Pelvis Slimming Belt

>> Premium Replacement Air Filter for Toyota RAV4

>> Stainless steel expanded metal wire mesh

>> Construction Equipment Concrete Floor Scarifying Milling Machine Gye-250

>> Hot Sale Good Quality Sanitary Lady Pads OEM Brand Sanitary Towel Super Absorbent Disposable Sanitary Napkins

>> Hot Sales 500 liter electric heating sandwich pot mini steam jacketed kettle

>> New Design High Efficiency Automatic Harvester River Garbage Water Grass Cleaning Machine

>> MW017 RFID Blocking Wallet Luxury Designer Leather Wallet Men Genuin Men′s Leather Wallets Card Holder for Men Clutch and Purses

>> Kraft Paper Making Machine and Carton Paper Making Machine

>> Fiber Laser in China Fiber Laser Cutting Machine

>> Wholesale Three Blank Wooden Bunny Keychains for Easter DIY Crafts and Decorations

>> 21cells Seed Starting Tray Plastic Tray for Greenhouse Garden Nursery

>> ENISO20344 Safety Shoes Impact Tester

>> Smart Eight 8 Color 360cm Air Jet Loom Textile Machinery Textile Weaving Machinery Shuttleless Loom Cotton Weaving Machine Tuck in

>> Best Price Stainless Steel Jacketed Tank Small High Pressure Reaction Kettle

>> Best Full Servo Automatic Baby Diapers Production Disposable Machine Manufacturer

>> TOKIT PAI PAI Rice Cooker Mini 1.5L Small Capacity Multifunctional Household 1-2-3 Persons Ceramic Coated Non-Stick Liner Pot Co