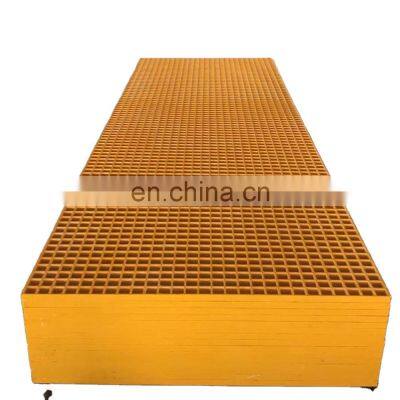

high strength industrial flooring molded fiberglass FRP grating

Product Description

Product DescriptionProduct Descriptionhigh strength industrial flooring molded fiberglass FRP gratingFiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. Fiberglass grating does not corrode like steel grating and is therefore used in corrosive environments to reduce maintenance costs.Material advantages:Strong bearing capacityStretch-proofHigh-temperature resistanceAnti-corrosionNon-flammableGood insulationNo rustNon-slipMildewproofAnti-shrinkageEasy to cutEnvironmental protectionApplication usage:ConstructionGuardrails, stairs, ladders, wall gratings, platforms, etc.Drainage treatmentDrainage ditch, drain grating, platform, structure, etc.Civil EngineeringFloors, sidewalks, bridges, tree protection, car washes, parking lots, Protect grating, etc.Chemical IndustryWork platform etc.Food processing and aquacultureThe platform, engineering guardrail, etc.Ocean industryPlatforms, fencing, sidewalks, etc.Details ImagesMolded FRP grating is composed of alternating directional layers of continuous glass fiber for strength, with resin to consolidate the fibers and provide the shape and corrosion-resistance. Molded grating has very high impact tolerance, as well as the highest chemical resistance of any fiberglass grating. It can be made slip-resistant by adding grit to the surface.Specification Fiberglass Grating has many sizes for you to choose.ThicknessmmMesh SizemmPanel SizemmOpen Area%Unit Weightkg4040*401007*300764602538*381220*366069523838*381220*366069855050*501220*3660721003038*381000*04069753825*1521145*290060763025*251220*3660648450*503819*191007*4007729238*38Production steps1. Stirring raw materialsResin, fiberglass fiber yarn, calcium powder filling, color paste, reagents, etc. are arranged in proportion, stirring for 20 minutes.2 . Draw yarnLay the alkali-free yarn layer by layer to improve the strength of the FRP grating.3 . Compression moldThe stirred raw materials are poured into the mold and compacted mechanically or manually.4 . Heat curingAfter the grating is heated for 20 minutes, the raw materials and yarn are fused together.5 . Cooling demoulding, mold liftingAfter the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.6 . Grinding, painting and washingThe FRP grating is polished and washed with a layer of varnish or water.PackingProduct packagingFiberglass Grating is usually packed by the pallet.To protect the FRP grating well, we also do Corner guard with film wrap.FAQQ: How can you guarantee your product quality? A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high quality supplier. Q: Are you a trading company or a manufacturing factory? A:We are a manufacturing factory with export qualifications. Our factory is one of the Best FRP products manufacturer in China since 2010. We have FRP products of high quality and various kinds. Q: I am interested in your products, could I get sample for free? A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is kindly offering your shipping account. Q: Can you do the design for us? A: Yes. With experienced teams in fiberglass product design and manufacturing, we can provide customizedshape,dimension, colors service.For more details, Please contact Cathy anytime, Contact info as following:

>> Four Wheel Mobile Lifting Platform with a Wide Operating Table Lift

>> Factory Price Automatic Signs Making CNC Bender Making Aluminum Profile Channel Letter Bending Machine

>> Reliable Heavy Duty Lifting Stage for Sturdy Industrial Performance

>> Automatic Center Pivot Irrigation System

>> Steel Round Flat Bar and Carbon Steel Cold Drawn Steel Square Carbon Steel Round Bar 1215 12L14 4140 4135 8620 Sj235 C45 S45c C35 S35c

>> 5 LED Bulbs Air Turbine High Speed Handpiece Air Turbine 2hole 4hole

>> Double-Shaft Shredder Blade Plastic Film Household Waste Packing with Crusher Rotor Knife Claw Knife Crushing Knife

>> Tower Fabrication Machine FINCM CNC Transmission Tower Power Transmission Steel Shear Shearing Marking Punching Machine

>> Wind Power Hydraulic Pipe Flange for Foundation Ring

>> Hot Sale Fishing Net Machine with Single Knot Nylon/HDPE Braided Sports /Fishing Net

>> Timing chain tensioner For Mercedes-Benz W201 W123 C123 1020501011 TN1037

>> 350ml Gourd Shaped Disinfectant Cleaner Plastic Bottle with Nozzle Can Be Customized

>> Pharmaceutical Automatic Soft Gelatin Capsule Encapsulation Filling Line Vitamin Fish Oil Omega Capsule Filler Softgel Capsule Making Machine

>> 150W High Quality 1390 Wood Laser Cutter Cutting Engraving Machine

>> OEM 42744451/42744452 headlight headlamp for chevrolet Trailblazer 2019

>> China Manufacturer Sensor Nursery LED Round New Design Night Light

>> HC-I006 High Quality Medical Gynecological examination bed gynecology chair stainless steel portable gynecology hospital chair

>> Hydraulic Sheet Metal Press Brake Machine Price for Sale

>> 32 Cavity Cap Compression Machine for 30/25 Water Cap

>> Spray Bake Paint Booth Automotive Spray Booth/Car Paint Spray Room CE Approve Custom AC-6900

>> jumper cable 4.3/10 Mini Din Plug Male Straight RF Connector For 1/2 Super Flexible Cable

>> Used Refurbished Medical Radiology Equipment Neusoft NeuViz Dual 40 kVA CT Scanner Machine for sale

>> Newest Front and Rear Bumper Spoiler Body Kit for Land Cruiser Prado

>> 269PLUS-D/O-261-100P-120

>> Commercial Electric Fryer Fries Fried Chicken Production Food Frying Machine

>> 8 Pcs Travel Makeup Brushes Set With Bag Wood Handle Professional Makeup Kits All In One

>> Plastic Pet Honey Jar Wide Neck Bottle Cans Blow Molding Making Machine

>> 200 L Efficient and Energy Saving Waste Plastic Agglomerators / Aggregate

>> Gots Oeko-Tex 100 Eco-Friendly Dark Gray Heat Transfer Printing High Quality File Pocket Felt Bag with Customers Logo

>> Novelty Magic Silly Putty Unicorn Slime Toy