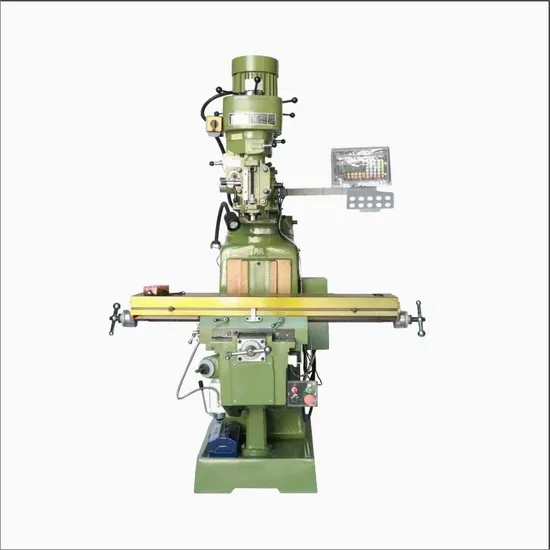

Lifting Table Milling Machine with Advanced Features for Enhanced Performance

| US$3,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

4S

Type

Worktable Milling Machine

Object

Hardware

Structure

Rocker

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Precision

High Precision

Certification

GS, ISO 9001

Condition

New

Transport Package

Wood Case

Specification

1750*1700*2200mm

Trademark

ALT

Origin

China

HS Code

8459590000

Production Capacity

2000 Sets Per Month

Product Description

Unveiling the extraordinary 4s Vertical Lifting Table Milling Machine, a masterpiece of engineering excellence, meticulously crafted in the heart of Taiwan. This state-of-the-art marvel is specifically designed to set unprecedented benchmarks in precision and efficiency for metalworking enthusiasts, offering an unparalleled experience for those who demand nothing less than the absolute best.Product Description

Mechanical CharacteristicMeticulously constructed with the superior Meehanna cast iron, this machine exemplifies extraordinary rigidity and unwavering stability. It promises enduring performance without deformation, ensuring robust and dependable operation that stands the test of time.The spindle, reinforced with a sophisticated combination of precision bearings, unleashes formidable cutting power and delivers exceptional accuracy. This empowers the machine with enhanced machining capabilities, turning it into a powerhouse of performance.Showcasing an innovative inverted hanging design, the end milling head excels in delivering outstanding precision. Its user-centric operation and convenient braking mechanism make operation seamless. For those seeking bespoke features, tailored solutions are readily available to meet specific needs.The three-axis screw nuts are crafted from premium-quality phosphorus meter copper, renowned for its excellent wear resistance. This ensures a prolonged operational lifespan, offering unwavering reliability and durability.The XY shaft slide is treated with advanced high-frequency annealing, significantly enhancing wear resistance. This treatment extends the machine's operational lifespan, ensuring continuous top-tier performance.An integrated lubrication system is seamlessly engineered to ensure optimal sliding performance, maximizing machine efficiency and longevity.

Product Parameters

1.Milling Machine Rotation Speed

Rotation speed is a critical factor that directly influences processing efficiency and cutting force. A higher rotation speed not only boosts cutting power but also enhances surface quality while minimizing residual stress on parts, resulting in superior machining outcomes.

Milling Machine Cutting Speed Cutting speed plays a vital role in determining both processing speed and quality. The optimal speed depends on factors such as material hardness, cutter material, and machine type, ensuring exceptional results for various applications. Milling Machine Processing Accuracy Processing accuracy is an essential performance metric, critically impacting both machining precision and part quality. It is influenced by factors such as cutting force, machine and tool rigidity, workpiece clamping accuracy, and initial machine tool errors. Milling Machine Precision Stability Precision stability is crucial for maintaining consistent machine accuracy throughout operation. It is affected by initial tool errors, deformation of the machine tool, and tool wear, all of which are essential to uphold quality.

| Product Name | ||

| Product Name | Milling machine | |

| Product model | 4S | |

| Product technical parameters | ||

| dimension | Table size | 1270*254MM |

journey | Left and right stroke(X) | 720MM |

| Front and rear stroke(Y) | 380MM | |

| Up and down stroke(Z) | 320MM | |

| Arm reach | 520MM | |

| Distance from spindle end face to table surface | 50-490MM | |

Principal axis coefficient | Spindle taper | R8 |

| Spindle speed | 80-5440RPM(16-speed) | |

| Spindle travel | 127MM | |

| Spindle horse power | 3HP | |

| Milling head | Milling head tilt Angle | 180° around / 45° front and back |

Machine profile dimensions | T-slot (Number * Size * Spacing) | 3-15.88*65MM |

| Machine size (L * W * H)(MM) | 1750*1700*2200MM | |

| Approximate machine weight | 1280kgs | |

| The configuration is as follows | Accessories name and specification | quantity |

Standard parts for machine tools | 1,Hand oil pump | 1 |

| 2,Work light | 1 | |

| 3,Organ board + protective glue | 1 | |

| 4,Lever | 1 | |

| 5,Tools and toolboxes | 1 | |

| 6,Operating instruction | 1 | |

Special parts for machine tools | 7,Two axis electronic ruler | 1 |

| 8, X-axis automatic feed | 1 | |

| 9, 6 "flat pliers | 1 | |

| Clamp plate | 1 | |

| 11, chuck | 1 | |

Detailed Photos

Packaging & Shipping

Professional Team

FAQ

1. What are the Payment Terms?

A: We accept T/T payments, requiring a 40% initial deposit upon ordering and the remaining 60% balance to be paid before shipment. This payment structure ensures a smooth transaction and timely processing of your order.

2. What are your trade terms?

A: We offer flexible trade terms including FOB, CFR, and CIF, giving you the freedom to choose the option that best suits your logistical needs and preferences.

3. When is the delivery time?

A: For our standard Vertical CNC Drilling Machine Center, we guarantee delivery within 30 days. For custom or specialized machines, additional time may be required. Please align your order placement with our provided delivery schedule to ensure timely receipt.

4. What is your minimum order quantity and warranty?

A: Our minimum order quantity is one set, ensuring accessibility for all customers. We also offer a comprehensive one-year warranty, reflecting our commitment to quality and customer satisfaction.

5. How are the machines packaged?

A: Each machine is meticulously packed in a robust wooden case, guaranteeing it arrives in pristine condition, ready for immediate use upon receipt.

6. How can I choose the most suitable machines?

A: Provide us with your specific requirements, and we will recommend the most suitable model tailored to your needs. Alternatively, you may select your desired model directly from our extensive range of options.

Alternatively, you can send us your product drawings, and we will identify the ideal machine configuration for your specific applications, ensuring optimal performance and efficiency.

>> Wholesale Cheap Colorful Plastic Handle 1.8L Thermos Vacuum Flask

>> Chx5263 CNC Vertical Milling and Turning Machine

>> Hfd-6000 Semi Automatic Pillow Compress Packing Machine Quilt Compress Packing Machine for Cushions Blankets Comforters Pet Mats

>> Marvell Q-Logic Qle2672 Card Dual-Port Fiber Mmf Optical Channel LC SFP+ Pcie Host 16GB Network Card

>> Tungsten Based Alloy W-Ni-Fe W-Ni-Cu Wcu High Temperature Strength Alloy ASTM Standards

>> Precision CNC Block Parts for 5 Axis Milling Machines

>> LC-A100ml Chemistry Laboratory High Temperature and High Pressure Stainless Steel Photochemical Reactor

>> Large CNC Gantry Milling Machine Machining Center GF-4025

>> Ferrice Magnet for Motor of Fitness Equipment 3.5kw

>> HDMI Input 7 Inch 1024X600 Capacitive Touch LCD Display for Raspberry Pi

>> Indoor and Outdoor Adult Fitness Equipment (QTL-1801)

>> Metal-Cutting CNC Tools Ssg Tool Wire Cut EDM Machine with CE

>> Window Machine/Vinyl Window Welding Machine/PVC Window Profiles Single Head Seamless Welding Machine

>> Top Sale 2024 Good Quality 16g 32 GB 64 GB Memory Card with Adapter

>> OEM RF Coaxial Cable Connector Rg316 Assembly Antenna Extender Cable Adpaper Coaxial Jumper Cable

>> Cleaning The Equipment, Cleaning The Pump for The Ball Spray 60e: Head12m Flow: 3800L

>> Clk6140s Slant Bed CNC Lathe Machine

>> Organic Shirakiku Dried Dashi Kombu Kelp Konbu, Dashima or Haidai Kombu Seaweed Algae

>> Greetmed Factory price medical cotton elastic self adhesive dressing bandage

>> Kdvm800la 24m/Min High Precision 5 Axis CNC Milling Machine

>> OEM ODM Factory Manufacturer Custom Plastic Medical ABS/PA/PP/PC Parts Injection Molding

>> Steel Hot Re Rolling Mills Supplier From China

>> China Cheap Price Auto Discharging Automatic Paper Tube Cutting Machine with Multi Cutter

>> 25kg/Bag L-Tryptophan 98% Feed Grade Additives for Broiler Chickens

>> China Manufacturer Genuine Automobile Steering System Auto Spare Parts Repair Kit Electric Power Steering Pump For Hyundai Kia

>> Combination High-Pressure High Lift Water Treatment Seawater Desalination High Flushing Pump

>> LED NSK W&H Dental Tool High Speed Handpiece with Low Speed

>> Ks12-9 1 Ton 1t Hydraulic Bagger Machine with Long Reach Boom Arm

>> AC 500kw 1000kw Resistive Loadbank 600kw 700kw 800kw Load Bank for Generator/UPS Test 50Hz/60Hz

>> Outdoor Beach Umbrella Artificial Palm Leaf Straw Hawaii Grass PP270 Cm