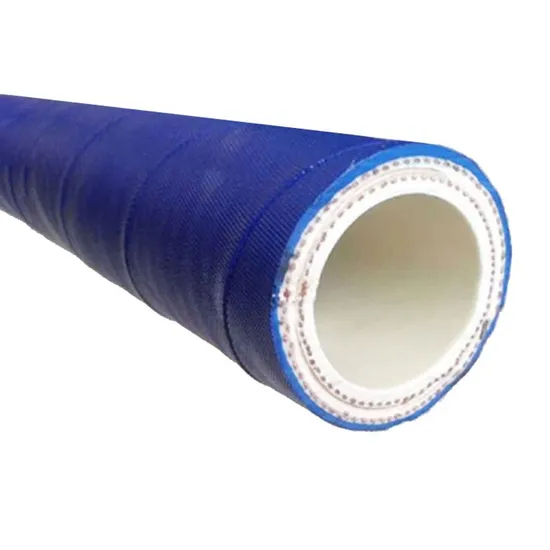

High Quality and Hot Selling Food Suction Discharge Hose

Basic Info.

Model NO.

Food Suction Discharge Hose

Color

Color

Product Name

EPDM Rubber Food Garde Hose

Keywords

EPDM Suction Discharge Food Hose

Tube

White, Smooth EPDM Rubber

Reinforcement

High Strength Synthetic Cord and Helix Wire

Cover

White, Wrapped EPDM Rubber, Weather Resistant

Application

Food and Drinking Water Hoses

Temperature Range

-40celsius - 120celsius

Inside Diameter

19-152 mm

Branding

Extrim Blast PRO

Working Pressure

10 Bar

Burst Pressure

30 Bar

Nominal Weight

0.67-8.84 Kg/M

Length

30-60 M

Ome & ODM Custom

Accept

Bending Radius

200-600mm

Transport Package

Nylon Belt, PVC Transparent, Plastic Reel

Specification

30-60 m

Trademark

GRANDFLEX

Origin

Qingdao, China

HS Code

40092100

Production Capacity

6000000m/Year

Packaging & Delivery

Package Size

120.00cm * 120.00cm * 120.00cm

Package Gross Weight

20.000kg

Product Description

Product DescriptionINDUSTRIAL HOSE

Custom designed and hand-fabricated hoses for a variety of industrial applications including FDA compliant high pressure sanitary hoses, chemical hoses, air hoses, petroleum hoses, brewery hoses, and material transfer hoses.Compared with civilian hoses, the industrial operating environment is more complex and harsher, and the equipment has more stringent requirements on the delivery pipes. Therefore, industrial hoses have strict specifications and standards from design, and material selection to production, transportation, and even final storage.

Product Parameters

| INDUSTRIAL HOSE | ||||||||||

| Tube | White,smooth EPDM rubber | |||||||||

| Reinforcement | High strength synthetic cord and helix wire | |||||||||

| Cover | White,wrapped EPDM rubber,weather resistant | |||||||||

| Temperature range | -40 Celsius to 120 Celsius | |||||||||

| Inside Diameter | Outside Diameter | Working Pressure | Burst Pressure | Nominal Weight | Bending Radius | Length | |||

| Inch | mm | mm | Bar | Psi | Bar | Psi | kg/m | mm | m |

| 3/4 | 19 | 31 | 10 | 150 | 30 | 450 | 0.67 | 200 | 60 |

| 1 | 25 | 36 | 10 | 150 | 30 | 450 | 0.84 | 250 | 60 |

| 1-1/4 | 32 | 45 | 10 | 150 | 30 | 450 | 1.20 | 250 | 60 |

| 1-1/2 | 38 | 52 | 10 | 150 | 30 | 450 | 1.52 | 250 | 60 |

| 2 | 51 | 65 | 10 | 150 | 30 | 450 | 1.96 | 300 | 60 |

| 2-1/2 | 64 | 78 | 10 | 150 | 30 | 450 | 2.95 | 400 | 60 |

| 3 | 76 | 91 | 10 | 150 | 30 | 450 | 3.44 | 400 | 60 |

| 4 | 102 | 120 | 10 | 150 | 30 | 450 | 5.06 | 500 | 60 |

| 6 | 152 | 172 | 10 | 150 | 30 | 450 | 8.84 | 600 | 30 |

LONG-LASTING DURABILITY:

This high-quality hose is made from imported raw materials and features a special elastomer compound, ensuring a super long service life and withstanding harsh working conditions.MULTI-PURPOSE APPLICATION:

This flexible hydraulic hose is suitable for various applications, including fuel, oil, and gas transmission, making it an ideal choice for users who require a versatile and reliable hose.TEMPERATURE RESISTANCE:

With a working temperature range of -40°C to +90°C, this hose can withstand extreme temperatures, making it perfect for use in diverse environments.USER-FRIENDLY WARRANTY:

Our factory provides a warranty, giving you peace of mind and protection for your investment.QUICK DELIVERY:

With our factory stock, we offer fast delivery, ensuring you receive your order promptly and can get back to work without delay.

FAQ

Q1. What hose do you provide?

Main rubber hose products:

high-pressure steel wire braided hose, high-pressure steel wire spiral rubber hose, steel wire winding hose, flame retardant, resistance to high temperature and high-pressure drilling hose, etc.

Q2. What are the product applications?

Mining, hydraulic support, hydraulic system, emulsification pump, construction machinery, coal mine underground water delivery, feng shui working face, water delivery, oil transportation, sand pumping, mud discharge, suction dust, exhaust gas, ash, engine gas pumping, Gas drainage/warm air duct.

Q3. What are your advantages?

High quality, complete specifications, stock in stock. company has passed ISO9001:2015 international quality management system certification and ISO14001:2015 environment management system certification. HOSAS18001:2007 certification of safety management system certification, mining products safety sign, etc.

Q4. What is your shipping way?

Express (DHL, FedEx, TNT), By air, Or Sea. We will choose one shipping way to suit customers' requests.

Q5. How do you guarantee your quality?

Firstly, we do quality tests during every process. We produce most components by ourselves, it starts from cutting raw material and machining roughly in the first step. casting , forging , punching , heat treatment , finish machining , painting , assembling , and finally packing , we will spot-check for each step.

Secondly, we will collect all comments on our products from customers in time. And try our best to improve quality all the time.

>> HIMA F6705

>> Premium Bridge Stone Polishing Machine for Quartz and Artificial Stones

>> Customized PP Plastic Sheet PP Board with Smooth and Flat Surface

>> Plastic UHMWPE HDPE Large Construction Road Mat Temporary Road Mats for Car Parking

>> 180-500 Degrees High Temperature Adjustable Solder Tool LED Digital Display Electric Soldering Iron with Power Switch

>> Huafon Good Leathers Soft Fake Full Grain Leather for Sandals Shoes Bags

>> Four-Row No-Tillage Corn Planter with Pneumatic Seeder Function

>> D50: 1-25um Ultrafine Powder Dry Grinding Fluidized Bed Air Jet Mill

>> Stone 1530 CNC Engraving Machine

>> Automatic Eyelet Pressing Machine for Pressing Eyelets Tightly on Fabrics

>> Automatic Rotary One Color PVC TPR Shoe Sole Making Machine

>> for Sur-Ron Light Bee X Large Capacity Battery Bluetooth Direct Replacement Ant BMS Surron off-Road Dirtbike Modified Battery

>> Matson Fast Ship USA Fba Dropshipping Logistics Service Amazon DDP Sea Freight Forwarder From China to USA Shipping Agent

>> Mzd Safe Freight Forwarding, China′s Best Cheap Ocean Shipping Services

>> High Precision CNC Surface Grinder, Surface Grinding Machine M3060 Table (600*300)

>> 550W 144 Half Cut Cells Monocrystalline Solar Panel

>> Hospital Surgical Autoclave Vertical Pressure Steam Sterilizer

>> Wholesale Customized 5m-Width PVC Coated Tarpaulin Tent Truck Cover Fabric

>> Precision Gap Bed Lathe with 52mm Spindle Bore and D6 Spindle Nose

>> China supply high quality air filter end cap for filter with free sample service

>> Wholesale Gym Shorts Running Workout Shorts Custom Women Sports Scrunch Butt Shorts for Women

>> q switch nd yad laser tattoo removal system/nd yag q-switch laser

>> Hot Selling Factory Price Durable Garbage Bins 120 Liter with Wheel

>> Single Phase Energy-Saving Controller

>> Advanced Polymer Rheometer for Computerized Material Analysis and Testing

>> Waterproof Interior White upvc Tempered Glass Modern Bathroom door casement bathroom doors

>> 24 Cavities High Speed Machine for CSD Cap

>> Z3050/16 Rock Drilling Machinery Double Column Hydraulic Radial Drilling Machine

>> Flexible, Split Wedge Gate Valve

>> Handmade Custom Made Family Portrait Canvas Oil Painting From Photo